Cooling Tower

Cooling towers reduce water temperature in the air conditioning process. Selecting a cooling tower needs information like capacity calculations, trusted brands, selection criterias, prices, etc. It leads to the wisest buy at the best price.

Cooling Towers Expert Selection and Pricing Guide

A cooling tower reduces the temperature of the water circulating in the condenser of air conditioners, power plants, refineries, and various industries, using a heat exchanger. In open-circuit cooling towers, water droplets fall onto packings or interface elements (boards) that spread the water over their surfaces, increasing wet surfaces and reducing water flow speed. This process creates more opportunities for sufficient heat exchange between the incoming water flow and the air passing through the cooling tower, effectively decreasing the water temperature within the cooling tower. Nevertheless, before starting the technical selection guides, the application and usage of cooling towers should be determined. So, here you are with the most common usages of HVAC cooling towers.

Review, Selection, and Pricing of HVAC Equipment

Applications and Uses of Cooling Towers

Cooling towers are considered key components in cooling and industrial systems, and their primary function is to reduce the temperature of circulating water and dissipate excess heat. Due to their effective performance, optimized energy consumption, and the important role they play in completing and enhancing heat exchange processes within systems, cooling towers are widely used across various fields. In general, cooling towers are commonly applied in the following areas:

- HVAC Equipment: In hospitals, medical centers, hotels, and large residential and commercial complexes, cooling towers are used to supply chilled water required for water-cooled and absorption chillers, as well as other cooling equipment. The stable performance of these units has a direct impact on cooling quality, thermal comfort, and the proper operation of HVAC systems.

- Heavy Industrial Equipment: In heavy industries, operating machinery and equipment generate a significant amount of heat. Cooling towers help reduce water temperature and transfer heat, preventing excessive temperature rise and contributing to improved safety, enhanced process efficiency and product quality, extended equipment lifespan, and prevention of production line shutdowns.

- Power Plant Cooling Systems: In power plants, especially thermal power plants, a large amount of heat is generated during the energy production process. Cooling towers play a vital role in rejecting this heat and cooling the water used in the plant’s operating cycles, thereby improving the overall system efficiency.

- Refinery Cooling Systems: Due to complex processes and high operating temperatures, refineries require continuous cooling systems. Cooling towers are utilized in these facilities to control temperature, enhance safety, and maintain the stability of refining processes.

- Manufacturing Plant Cooling Systems (Production Processes): In many manufacturing plants, temperature control is critical at various stages of the production process. By providing a stable supply of cooled water, cooling towers help maintain product quality, increase production speed, and reduce equipment wear and tear.

- Wood, Molding, and Casting Industries: In wood processing, molding, casting, and plastic injection industries, equipment and molds are exposed to high temperatures. The use of cooling towers in these industries ensures effective temperature control, improves final product quality, and increases the service life of molds and machinery.

Choosing the Right Cooling Tower Capacity

When choosing the appropriate capacity for a cooling tower, it is essential to consider that the maximum temperature difference between the “input and output water” from the cooling tower (ΔT) will always be lower than the difference between the “input water temperature and the wet bulb temperature.” In a more straightforward explanation, the minimum temperature of the water exiting the cooling tower will consistently be a few degrees higher than the humid air temperature at the location where the cooling tower is installed.

For instance, in cities such as Tehran, Erbil, Kabul, Sulaymaniyah, Aleppo, Mosul, Kirkuk, and others with similar climates during summer, the maximum temperature of humid air is approximately 23 ℃, and the minimum temperature of the water leaving the cooling tower will be around 26 ℃.

Factors to Consider When Choosing the Cooling Tower Capacity

Another important aspect is that even under optimal conditions and dry weather, a cooling tower's ability to decrease output water temperature compared to input water is limited to around 30℃.

Furthermore, suppose the output water temperature of industrial processes in a factory in the city of Tehran is high and needs to be reduced to around 26℃, using one, two, or even three open-circuit cooling towers in series. In that case, ensure that the water entering the first tower isn't hot enough to damage the cooling tower's packing. Consequently, if an open-circuit cooling tower is used to lower the water temperature of production processes, the water entering the tower should not exceed 70℃.

Suppose the water temperature is higher than this. In that case, other methods should be employed to reduce it, such as exposing the water to ambient airflow or using water-to-air plate heat exchangers before entering the cooling tower.

Also, the lower the relative humidity of the air in the place where the cooling tower is installed, the lower the temperature of the moist air in the place, and as a result, the cooling efficiency and the decrease in the temperature of the water leaving the tower will be higher.

Notes:

An important point regarding the capacity calculation and selection of the cooling tower for all types of water-cooled air conditioning projects and cooling towers required for the production line processes of workshops or industrial factories accuracy and checking of the weather and climate conditions of the project site. Especially if the relative humidity and temperature are high in the summer.

Suppose the project is in an area with a moderate climate, such as Tehran, Karaj, Mashhad, Shiraz, Kermanshah, Khorramabad, Semnan, Isfahan, Sulaimaniyah, Erbil, Mosul, Aleppo, Mazar-e-Sharif, Kabul, Kirkuk, Tabriz, etc. The amount the heat transfer and water temperature reduction of the cooling tower are somewhat different based on the moisture temperature of the ambient air compared to hot and dry climatic conditions, such as the cities of Yazd, Kerman, Zahedan, Zabul, Baghdad, Oman, Medina, Karbala, Najaf, etc.

Cooling Towers Types in terms of Material and Function

The overall function and the structural materials in typical use on cooling towers for HVAC projects include:

- Body Material: Galvanized, Fiberglass, and Concrete

- Airflow Suction: Natural and Forced (Mechanical Current)

- Airflow and Water Synergy: Crossflow and Opposite Flow

- Water Distribution System: Watering Nozzle - Basin - Watering arms

- Body Shape: Round and Square

- Operation: Open Circuit and Closed Circuit

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

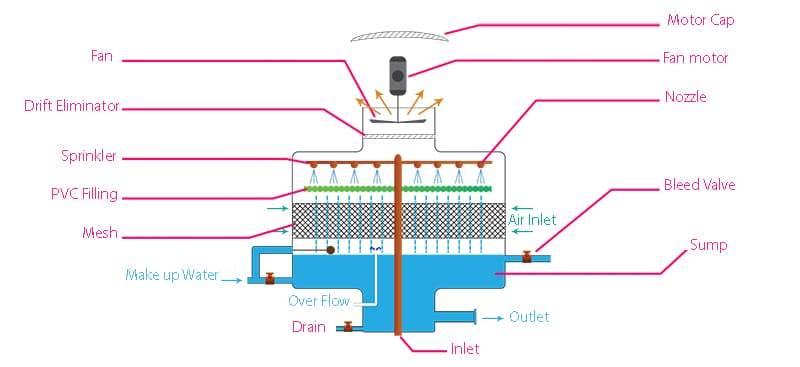

Open-Circuit Cooling Tower

Open-circuit cooling towers are those regular cooling towers used in air conditioning systems where the water (heat transfer fluid) is cooled after entering the tower and spraying on the packings (which increases the contact surface with the airflow inside the tower). After collecting the water in the lower pan of the tower, it is pumped back to the heat exchange cycle.

When choosing an open-circuit cooling tower, the following information must be considered:

- Cooling tower shape (round or square)

- Cooling tower body material (galvanized or fiberglass)

- Water flow rate for the condenser or cooling tower (3 GPM per ton of refrigeration for compression chillers and up to 5 GPM per ton of refrigeration for absorption chillers)

- Dry and wet bulb air temperatures of the cooling tower installation environment during summer

- The temperature difference between the input and output water in the cooling tower.

- Difference between the temperature of the water leaving the cooling tower and the wet-bulb temperature of the ambient air (Approach Range for industrial use)

- The cooling tower's capacity and flow rate are proportional to the desired chiller capacity in terms of a ton of refrigerating (TR or TOR) or proportional to the volume and temperature reduction of circulating water in industrial processes and factories.

Note: In cooling towers used for industrial, telecommunications, etc., which are also used in the cold seasons of the year, the use of electric heaters (elements) in the pan of cooling towers is required to prevent water freezing and damage to the device.

Extra: Every ton of refrigeration equals 12,000 BTU.

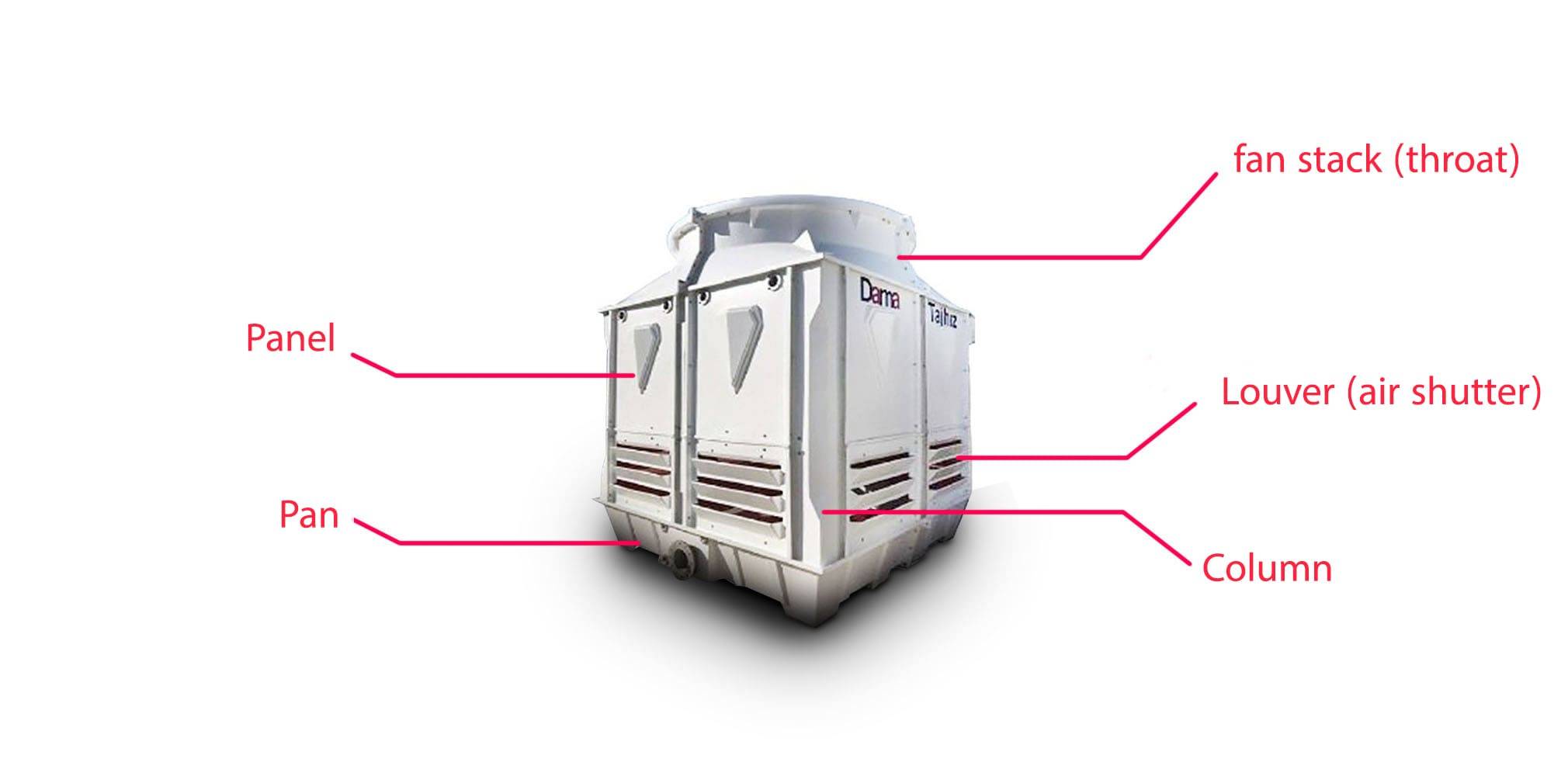

Open Circuit Cooling Tower Exterior Parts

External components and components of the open-circuit cooling tower

The external components and parts of the open circuit cooling tower are:

- Fan stack (throat)

- Louver (air shutter)

- panel (the shell)

- Pan

- Column

Closed Circuit Cooling Tower

In closed-circuit cooling towers, water is sprayed onto the packings while air flows through the tower, cooling the circulating water. This water comes into contact with a coil containing a heat transfer fluid, such as water or oil, which reduces the temperature of the fluid flowing through the closed-circuit coil. Due to the additional equipment needed, such as heat exchange coils and pumps, closed-circuit cooling towers are generally pricier than open-circuit ones.

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

Hybrid Cooling Towers

Hybrid means combining two or more different approaches to create a better approach. Therefore, it can be said that the hybrid cooling tower is a special and complete combination of the closed circuit and open circuit cooling towers, designed to improve the overall performance, increase efficiency, and take advantage of the advantages of these two types of cooling towers. Due to its special design, the hybrid cooling tower has higher dimensions and height and a higher initial construction cost than open-circuit and closed-circuit cooling towers.

Also, the average annual water consumption in the hybrid cooling tower has been greatly reduced, called a low-consumption hybrid cooling tower. In this method, the cooling fluid passes through the coil of the cooling tower (such as a closed-circuit tower) and is cooled. It passes through the heat exchanger or condenser and is cooled again in the vicinity of the cool water entering from the pan of the hybrid cooling tower.

Dry Cooling Towers

Dry cooling tower refers to air condensers of compression refrigeration systems or air-to-fluid heat exchangers (air coolers), which act like a heat exchanger between water and air. In this system, water and air do not have any direct contact with each other, so water does not evaporate (in this way, water consumption in the air-cooled condenser is zero).

The operation of the dry cooling tower or air-conditioning condenser is as follows:

Hot water from industrial processes enters the cooling tower through pumps and pipes.

This hot water flows through the copper coil (or reciprocating copper pipes).

At this stage, indirect contact between weather and climate occurs: In this way, the outside air is sucked into the cooling tower by the fans in the coil's outer part. Then, this air collides with the surface of the hot fluid transfer tubes, and as a result of these continuous collisions, the fluid coming out of the dry cooling tower loses its heat to the dry temperature of the surrounding coil and cools down.

Cooling Tower Main Parts

Every cooling tower consists of four main parts. These are as follows:

- fan stack (throat)

- Louver (air shutter)

- panel (wall)

- pan

- a column

Cooling Tower Coil

The cooling tower coil is one of the components of the closed-circuit cooling tower. These coils function similarly to the packing and nozzles in open-circuit cooling towers. The key difference is that the nozzles spray water, while coils in closed-circuit towers circulate water through pipes, and the heat exchange occurs indirectly through the surface of the metal pipes.

Closed-circuit cooling tower coils are classified into copper, steel, and galvanized categories based on the material used.

Cooling Tower Fan

The cooling tower fan is the main component of a cooling tower, significantly influencing its efficiency. These fans circulate vast amounts of air through the device, requiring maximum efficiency and minimal vibration for optimal performance.

Factors such as blade width, impeller diameter, and fan rotation speed contribute to varying airflow in different fan types. Like other AC fans, cooling tower fans can be categorized into centrifugal and axial types, most commonly used in round and square cooling towers.

Cooling Tower Drift Eliminator

An eliminator or drip catcher is typically installed above the nozzles to minimize the number of water droplets drifting from the top of the cooling tower.

These are commonly made of PVC or PP materials. PVC eliminators often feature a honeycomb design, while PP eliminators use a V-bar design, reducing water loss to less than 0.02% of the tower's circulating water.

Cooling Tower Packing

The packing inside the cooling tower must be selected based on the appropriate design and material. Typically, cooling tower packings are made from 400-micron-thick, antibacterial, pharmaceutical-grade PVC or splash/random splash packings made from polypropylene (PP), depending on the buyer's preference and order.

Eco-Friendliness of the Cooling Towers

All types of cooling towers play a significant role in reducing water consumption by cooling circulating water and returning it to the refrigeration or production cycle. Therefore, it is highly recommended to use them, especially if they are air-cooled (condenser), in regions and countries with water shortage problems such as Iraq.

This also helps to reduce the pressure on the underground water source. The cooling tower device itself does not pose any risks to humans and the environment. As a result, these devices can be extremely useful in preserving the environment and reducing the pressure of industrial factories on the environment.

Cooling Tower Maintenance and Care

Knowing and understanding the various types and their benefits and disadvantages is crucial for maintaining a cooling tower, as well as the following factors:

- To protect the tower body against harmful ultraviolet rays, as cooling towers are often in open environments and exposed to direct sunlight, applying a suitable Nopitel Clickal Gel (NPG) coating is essential.

- The main structural elements and secondary parts (screws, nuts, etc.) should be made from stainless steel or galvanized iron, as internal cooling tower components are in constant contact with water.

- Considering that the water temperature reduction in the cooling tower is an evaporative process and is accompanied by the evaporation of a significant volume of water, the degree of hardness and the quality of water in the cooling tower, especially in the open circuit cooling towers, are significant. Failure to maintain and control water hardness in standard conditions (less than 50PPM) causes sedimentation and adhesion of water sediment to the packings inside the device and, eventually, in addition to reducing the lifespan and efficiency of the device. It even causes the internal pipes of the chiller condenser or heat exchanger to clog, resulting in financial losses.

- The necessity of using a stainless-steel filter on the bottom of the cooling tower pan and the way the water comes out of the device and continuous visits to make sure that the meshes (holes) of the filter are not clogged due to the prevention of any blockage in the way of the cooling system pipes, such as the condenser, is a chiller.

- To control and adjust the water hardness level of the cooling tower, in addition to the necessity of using resin hardeners in appropriate capacities or electromagnetic hardeners, the method of flushing should also be used to reduce the accumulation of hardness and water salts in the water. Used a cooling tower pan. Its method is that, according to the cooling tower's capacity, every 30 to 45 days, the facility's operator must completely drain the water and salts of the cooling tower pan from the lower part of the pan, and the new water is though. Replace the bottom one.

The New Generation of Cooling Towers

The new generation of cooling towers is cube-shaped and cross-flow type, with the possibility of air suction from only two sides of the device. Using the new design and technology in the construction of cross-flow cubic cooling towers, the limitations and disadvantages of the old generation of cooling towers have been completely removed.

The most important advantages of the new generation of cubic crossflow cooling towers are as follows:

- The ventilation fan's sound has been reduced significantly by using special aluminum alloys and designing it with specific angles.

- Installation of the inspection valve for easy access to the cooling tower's interior to reduce the device's periodic services (in the case of the customer's order and specified in the purchase order invoice).

- It does not occupy much space, with the possibility of air suction only from its two sides, especially in high capacities, and the arrangement of new cubic cooling towers side by side without needing lateral distances from each other (needs less installation space).

- Significant savings in water and electricity consumption of the device.

- Using new technology to evenly distribute water on the internal packings of the cooling tower by the gravity method.

- No need for a water dispenser and complete elimination of problems caused by it (such as clogging of nozzles and broken shafts, and related financial losses).

- Separation of capacity and construction of smaller cooling towers in the form of multi-cells in more suitable capacities by having several electric motors and smaller propellers, and eliminating the complete vibration of the device

The Function of the Cooling Tower Multi-Stage Thermostat

By using a multi-stage thermostat and installing it on the water pipe coming out of the cooling tower pan to the chiller condenser, it is possible to reduce the water temperature by changing the speed of the electric motor of the cooling tower fan according to the command sent to the tower inverter, based on the set temperatures of the gradual thermostat. Controlled the output from the cooling tower (input to the condenser).

Suppose the intelligent control system is not installed. In that case, it is necessary to install at least one thermostat with the possibility of turning off and on the fan motor of the cooling towers for the times when the weather is milder, on the outlet water pipe from the cooling towers to the collector of the cooling towers' pumps. To be able to have more control over the temperature of the water coming out of the cooling tower.

DamaTajhiz: The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

If you need advice regarding the selection, calculation, and purchase of household and industrial cooling towers, you can contact the sales expert of DamaTajhiz HVAC.

As the first and most reliable sales collection of all construction and air conditioning equipment in Iran and the Middle East countries, the technical information and guaranteed prices of all types of cooling towers in various capacities have been presented in the specialized collection of Damatajhiz for intelligent and optimal review, selection, and purchase.

At any stage of reading this article, you can contact our experts in the specialized collection of heating equipment; in addition to getting the necessary advice, you can experience a satisfactory purchase from this dynamic collection.

Suggestion for Replacement of the Old Cooling Towers

Suppose you plan to replace your old, worn-out cooling tower with a new fiberglass one. At the same time, you check the capacity, the volume of circulating water, the tower’s dimensions, the chassis, and the possibility of installation in the place of the old cooling tower. In that case, you might as well want to pay attention to the flow rate of the circulating water pump of the new tower, especially when replacing a galvanized or Marley one with a fiberglass cooling tower.

Here are some extra key points to consider when replacing your cooking tower:

- The thickness of the fiberglass body

- An anti-UV coating

- Galvanized bolts and body

- Having a Super Blade Fan

- The type and amount of the packing

- The strength of the stands

- The quality of the electromotor fan

- Quality of the stairs or the ladder

Water Softener & Filtration System in Cooling Towers

Various microorganisms present in running water can grow and multiply in the cooling tower water. As they adhere to the pipe and other components of the device, these microorganisms can cause corrosion and damage, ultimately diminishing the system's efficiency. Furthermore, bacteria and algae in the cooling tower water can corrode parts and lead to deposits.

Calcium and magnesium hardness are the primary factors contributing to deposits in cooling tower and chiller condenser components. These deposits obstruct proper heat exchange and decrease the efficiency of the equipment by creating a hard surface.

Contaminations, such as airborne dust, can also cause deposit formation in the cooling tower and chiller. When these materials enter the cooling tower and become damp, they create a mud-like layer in the pipes and other components, significantly reducing the system's efficiency.

A water softener and filtration effectively prevent deposit formation on various parts and surfaces of the cooling tower and chiller. Additionally, incorporating appropriate anti-scaling agents for the water aids in preventing deposit formation and maintaining the device's efficiency.

Using water softeners and filtration directly correlates with reducing repair costs and increasing the cooling system's efficiency. To prevent deposit and corrosion of pipes and components (as well for related equipment like chillers). It is advisable to add appropriate anti-scaling agents and use filters compatible with the cooling tower.

Estimating Water Compensation of Cooling Towers

In normal conditions, the approximate water consumption for all types of cooling processes in cooling towers can be considered as 0.2 to 0.3 liters per minute for each nominal ton of tower capacity. However, it's important to note that water consumption in cooling towers depends on factors such as relative humidity, ambient air temperature, and the temperature difference between the incoming water and ambient air.

When the cooling tower is in the refrigeration circuit, the amount of compensation water can be calculated based on the type of chiller compressors (for water-cooled and air-cooled chillers), according to the following estimates:

- For chillers with screw compressors: 4 GMP/100 tons

- For chillers with centrifugal compressors: 4 GMP/100 tons

- For chillers with reciprocating compressors: 4 GMP/100 tons

- For absorption chillers: 8 GMP/100 tons

At DamaTajhiz HVAC team, we offer various cooling towers at competitive prices, ensuring you can find the perfect solution for your needs. Our comprehensive technical specifications provide all the information you need to make an informed decision. We pride ourselves on offering original warranties and fast nationwide delivery for all our products. With DamaTajhiz, you can easily choose the ideal cooling tower for your requirements.

Cooling Tower Industrial Applications

Using cooling towers in the industry effectively removes unwanted heat from molds, processes, or heat exchange of one fluid with another. In this operation, hot water from industrial equipment or any other heat source enters the open-circuit or closed-circuit cooling tower and spreads evenly on top of it. As the water flows down the cooling tower, the flowing water is evenly sprayed on the packings (in open-circuit towers) and on the coil (in closed-circuit towers) to increase the contact of water with the air.

Therefore, heat transfer and reduction of water temperature in the tower are done through the process of water evaporation. While the water evaporates, the heat is taken from the water. Finally, after its temperature decreases, the water is collected in the lower part of the cooling tower pan. Then, cool water is pumped towards the desired devices in the direction of the product production process to prevent the temperature of these devices from rising too much, and this cycle is constantly repeated.

As mentioned before, one of the most important points regarding reducing the water temperature of industrial processes by using open-circuit cooling towers is to pay attention to the temperature of the water exiting the process or the water temperature that we want through the method of evaporative heat transfer by the cooling tower.

The use of industrial cooling towers to reduce the temperature of circulating water in product process operations in all industrial factories, such as glass and ceramic production, wood and paper industries, pharmaceutical and medical industries, food industries (dairy and oil production), petrochemicals, etc. It is widely used.

How Do Industrial Cooling Towers Work?

Industrial cooling towers efficiently remove excess heat from one fluid to another using water. In this process, hot water from industrial equipment or other heat sources enters the open or closed-circuit cooling tower and spreads evenly on top.

As the water flows down the tower, it covers a large surface area, increasing air-water contact and promoting heat transfer through evaporation. As water evaporates, it loses heat. Finally, after the temperature has been reduced, the water flows into the tower pan at the bottom. The cooled water returns to the primary heat source, and the cycle repeats.

Factors to Consider when Using an Open-Circuit Cooling Tower in Industrial Processes

If you want to use the open circuit cooling tower and related packings to cool the hot water of industrial processes, install a water pool next to the cooling tower device so that the hot water enters the pool before entering the device, where it evaporates during the water evaporation process. It is necessary to reduce its temperature to some extent and make it suitable for entering the cooling tower.

A critical point in industrial cooling towers is the relatively high temperature of the output water from production processes. According to the quality and material of the open circuit cooling tower packings, these packings are usually resistant to a temperature of 55 and a maximum of 57 degrees Celsius in the best conditions, and for higher temperatures, other solutions should be used as an alternative.

Cooling Towers vs. Condensers

One of the common questions about cooling towers concerns the similarity of the operation of evaporative condensers or air-cooled condensers with the closed-circuit cooling towers and the main difference between them.

In general, in terms of the evaporative cooling process, closed-circuit cooling towers function similarly to evaporative condensers to dissipate heat from domestic and industrial cooling systems. Nevertheless, the difference is that none of the closed-circuit cooling towers use refrigerant gas to reduce the temperature like air-cooled condensers do; rather, they effectively reduce the temperature through circulating water in the system. So basically, the operating systems of these two devices (closed-circuit cooling towers and air-cooled compressors) are different.

Tips for Transporting and Installing Cooling Towers

When transporting and installing cooling towers, consider the following:

Diameter of the Cooling Tower

Suppose the diameter of the fiberglass cooling tower you purchased exceeds 220 cm. Transporting the tower separately to the project site is advisable to prevent damage during transportation. The final assembly of cooling towers with diameters greater than 220 cm would be completed on-site with an additional fee.

The Stand of the Cooling Tower

The stand of the cooling towers is designed and constructed according to the exact weight and dimensions of the tower to ensure that it can support the tower's weight by the building's structure and avoid any issues related to the architectural appearance of the building. If a crane cannot move the integrated tower at the project site, refrain from ordering the assembled cooling tower.

The Location of the Cooling Tower

The installation location of the cooling towers must have no obstacles, ensuring the free flow of fresh air into the tower. Additionally, when multiple towers are used nearby, take measures to prevent the air exiting one tower from directly entering another, as this may reduce the device's efficiency.

Once the appropriate capacity is selected and placed outdoors with unobstructed airflow, achieving optimal efficiency should not be an issue.

However, if the cooling tower is installed inside a building or enclosed by walls, consider the following:

- There must be ample, unobstructed space around the tower to allow fresh air to reach the cooling tower.

- The humid air exiting the cooling tower must be discharged to prevent it from returning and recirculating within the tower. Recirculation of such air increases the wet temperature of the air entering the tower, causing the water in the system circulation at the exit from the cooling tower to remain warm.

- When multiple towers are installed nearby, preventing air recirculation is especially important.

- The installation location of the cooling tower is determined by various factors, including the sound intensity at a 10-meter distance, the structural strength of the location, additional equipment costs, and architectural considerations.

Due to the importance of fan balance in the performance of the cooling tower and its direct relationship with the lifespan of the fan and electromotor, to maintain the dynamic balance of the air circulation fan, pay attention that all types of cooling towers should be installed in a completely horizontal and level position at the installation site.

Factors to Consider When Buying Square or Round Cooling Towers

When looking to buy a cooling tower, consider the following factors:

- Capacity and Dimensions: Ensure the cooling tower is suitable for the space where it will be used, as it comes in various types, capacities, and uses.

- Water Make-Up Requirements: This will help determine your project's appropriate model and capacity at the right price.

- Characteristics, brand, and type of the cooling tower: Research these factors to make an informed decision.

Review, Selection, and Pricing of HVAC Equipment

Cooling Tower Price

The price of a fiberglass cooling tower varies depending on its type, capacity, and brand. To simplify the process of selecting and purchasing a cooling tower, it's essential first to determine the necessary tower capacity.

All cooling towers featured on the DamaTajhiz website have product identifiers and appropriate pricing. Any discounts sought by customers have already been included in these prices.

Dear users;

Studying the stated information above to obtain additional information to purchase the types of cooling towers. You can also contact the experts of the AC equipment by dialing one of the extension numbers 117-119-120-126-317 to get advice or to ask your questions.

Dear users, while thanking you for the trust you put in the technical opinions of air conditioning sales experts of DamaTajhiz, it should be noted that the choice of the desired product brand based on history, brand strength, service, and product price is ultimately determined by the buyer. But in the field of cooling towers, most users and buyers choose and buy best-selling brands such as Ventilation, Saran, DamaTajhiz, Saravel, and G Plus due to their quality, price, and after-sales service.

Moreover, since Damatajhiz HVAC is one of the primary groups specializing in heating equipment, it is the first and most viewed authority for selling air conditioning equipment and an official member of the heating and air conditioning equipment sellers' union. Therefore, it is now safe to say that we provide all kinds of cooling towers in the Middle East region. Hence, if you are from the same country in the area and you need a cooling tower, please place your order with our expert sales team. Product warranty and a reasonable price are included.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.