Heat Exchanger

Heat exchangers (including shell and tube, plate, and double-pipe types) are widely used in industrial applications and building services for heat transfer between two fluids. Below, the types, technical specifications, selection guidelines, and the best prices of plate heat exchangers and shell-and-tube heat exchangers are presented.

Heat Exchanger Expert Buying Guide and Price List

As it is clear from the name, heat exchangers are kinds of heating equipment, responsible for exchanging heat between two fluids, such as water, gas, oil, air, etc. There are two common types of heat exchangers: the shell tube and the plate heat exchanger.

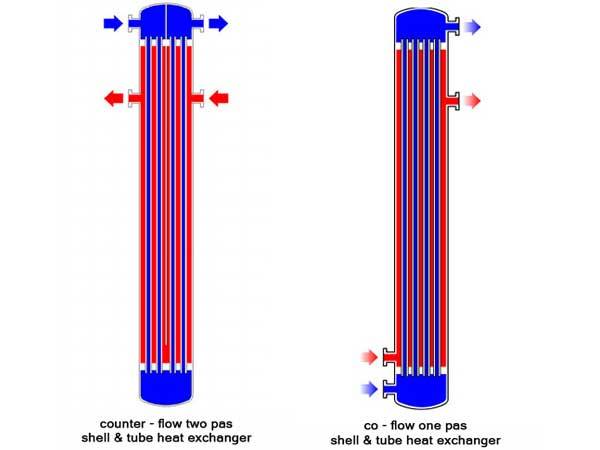

Shell and tube heat exchangers have different types according to the number of tube passes, and the simplest of them has one shell pass and one tube pass, which you can see in the picture below.

Review, Selection, and Pricing of HVAC Equipment

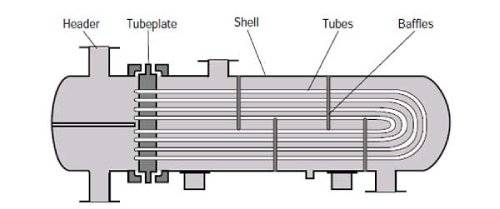

In some models of heat exchangers, there are plates called "Baffles" to increase the displacement coefficient of the fluid inside the shell by creating turbulence and a transverse velocity component in the flow. Those heat exchangers that have baffles are usually produced with one shell pass and two pipe passes or two shell passes with four pipe passes.

Types of Heat Exchangers

As mentioned before, there are three types of heat exchangers based on how they function: shell and tube, plate, and air-cooled or finned heat exchanger. But in terms of how water circulates through them, they are also divided into three types, which are parallel flow, asymmetric flow, and cross flow, which we will examine in the following.

1. Shell & Tube Heat Exchanger

These Exchangers are widely used in the facilities, air conditioning, swimming pools, and even chemical industries. As its name suggests, the shell and tube heat exchanger consists of a large cylindrical tank (shell) at high pressure and a pipe row inside of it.

The water runs inside the tubes as hot/cold water or steam flows around the tubes. Due to the large number of these pipes and the high contact surface it creates, heat is transferred to the liquid inside the pipes and heats up or cools down the liquid.

In shell and tube heat exchangers with baffles (flow-directing plates), the fluid flows from side to side in a crosswise direction.

The Piping: The pipes are responsible for heat exchange as they are in contact with fluids of different temperatures on both sides. The pipes (which vary in size and material) are usually made of copper. Still, depending on the application, they can also be made of stainless steel, nickel, aluminum, brass, or titanium.

However, according to the coefficient of heat transfer of the fluid inside or outside the pipes, whichever side this coefficient is lower, it is possible to use pipes with fins from the other inside or even the outside, which naturally have a higher construction cost.

The Shell: The shell (along with the tube sheets) holds the pipes and connections of inlets and outlets. Moreover, heat transfer is also done inside the shell, and the thickness of the shell depends on the working pressure and the diameter of the shell.

U-shaped heat exchangers have the least expensive structure because only one U-shaped tube bundle is needed. However, the insides cannot be cleaned mechanically due to the U-shaped bend and non-disassemblable shell; therefore, acid washing must be done to clean this type of heat exchanger. An even number of pipes are used in this type of heat exchanger, but thermal expansion is not limited.

Stainless steel is usually used in the construction of the shell of this heat exchanger. Because its heat transfer should be at the lowest level and its pressure tolerance should be at the highest possible level, on the shell of the heat exchanger, the water entry and exit path, hook, hanger, drain connection, installation location of the sensor's safety valve and etc. should be considered.

Shell and tube heat exchangers have different arrangements in terms of fluid flow on the shell side and the tube side and are selected and used based on the heat transfer level, working pressure, coil pressure drop, manufacturing methods, corrosion control, and cleaning issues.

Baffles are used in shell and tube exchangers to increase the heat transfer coefficient on the shell side and also to keep the tubes in place in a better way.

|

|

How Shell and Tube Heat Exchangers Work

The operation of the shell and tube heat exchanger is such that fluid flows in the tubes that are placed together in a group, and at the same time, another fluid with a different temperature between the shell and the outer wall pipes flows.

Two fluids with different temperatures pass through the shell and tube heat exchanger in close proximity to each other and without direct contact, which causes heat exchange between the two fluids.

This heat transfer takes place through the walls of the pipes. In order to increase the heat transfer coefficient, barriers called baffles are embedded inside the shell, which prevent the rapid passage of the fluid inside the shell, resulting in better efficiency of the shell and tube heat exchanger.

The sides of the shell and tube heat exchanger have two connections. The connection of the relevant pipes should be such that the entry of one fluid and the exit of another fluid take place on the same side of the heat exchanger.

Tube sheets are also located at the top of the tubes, and in addition to keeping the tubes, they help separate the two fluids from each other so that there is no direct contact between them.

This type of heat exchanger has features such as high pressure and temperature tolerance and simple design, which has made it widely used in various industries.

In other words, the shell and tube heat exchanger has become one of the most widely used heat exchangers due to its favorable structure and effective performance and is used in many industries such as oil and gas, petrochemical, refrigeration systems, and especially for the provision of hot water required by private and public swimming pools.

Shell & Tube Heat Exchanger Advantages in Industries

Among all the advantages of shell and tube heat exchangers the following can be mentioned:

- In a small volume, they create a large surface for heat transfer.

- Can be used for a wide range of materials.

- They are easily cleaned.

2. Plate Heat Exchanger

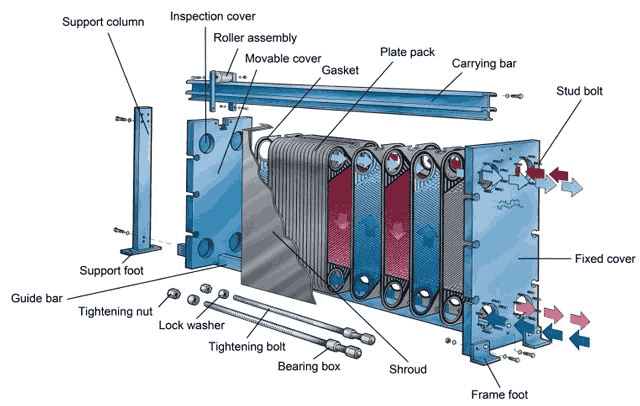

The plate heat exchanger, which has been used in the Industry for over a hundred years in terms of structure, mainly has 4 models, but the gasketed and brazed or welded models are the most important ones.

Gasketed Plate Heat Exchanger

Gasketed plate heat exchangers are mainly used in industries such as instructional facilities, the air conditioning industry, the food industry, the petrochemical industry, the paint industry, the oil industry, etc., due to the frame cost compared to welded model (with the same size and capacity).

Other advantages of gasketed plate heat exchangers are the ability to increase the capacity, easy repair, service, and wash.

Brazed Plate Heat Exchanger

Brazed (welded) plate heat exchangers, along with water softeners, are mainly used to provide hot water for buildings, swimming pools, floor heating systems, oil cooling, and even as evaporators and condensers in chillers, which should be exactly calculated based on the project (except for the spa). In this regard, you can consult with the experts of DamaTajhiz HVAC Group.

Note: Regarding price comparison of heat exchangers in the same capacity, all types of brazed plate heat exchangers have a more affordable price.

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

How Plate Heat Exchangers Work

The method of plate heat exchanger is that a number of thin plates are placed one after another, between which cold and hot fluid flow tubes are connected to the plates one by one. In the space between the plates, hot fluid and cold fluid flow alternately.

This structure increases the efficiency and proper heat exchange of two fluids due to heat transfer between the walls of the plates.

The plate heat exchanger is more limited than other exchangers in terms of temperature and pressure tolerance. Still, due to its high heat transfer surface and smaller dimensions, it is widely used in places with limited space or in cases where we need fast heat transfer.

In general, the plate heat exchanger with the structure of plates and alternating flow of fluids has a faster performance in heat transfer and is used in various industries due to its wide applications.

But it goes without saying that the essential prerequisite for using a heat exchanger, especially plate heat exchangers, is the installation and operation of suitable hardeners to prevent deposition and loss of thermal efficiency on the surfaces and walls of heat transfer in heat exchangers.

Plate Heat Exchanger Advantages

Plate heat exchangers have some advantages to shell and tube heat exchangers due to having high heat transfer coefficient, much smaller dimensions, and higher efficiency (especially if a water softener is used); they can supply hygienic hot water in no time without the need for a storage (coiled and double-wall sources).

Plate Heat Exchanger Installation Tips

Here are some great tips that can be useful when it comes to the installation of a plate heat exchanger:

- The Installation Position: The plate heat exchanger can be installed horizontally and vertically. Still, in both situations, it should be noted that the exchanger is installed so that the air can easily escape from it. In the horizontal position, it is better to have the heads of the water pipes upwards, and in the vertical position, the heads of these pipes should have a slight slope.

- The Stand or Chassis: For the installation of large plate heat exchangers, it is better to consider a chassis to make sure it is fixed in place without imposing extra weight on the pipes or directly on the floor of the engine room. The most important point in installing a plate exchanger is how to connect the water input/output pipes.

- The Water Port: In most plate exchangers, the water input and output are on the same side, but they must be in opposite directions. However, in some heat exchangers, due to the existence of baffles, observing the correct direction is effective on the exchanger's efficiency.

- The One-Way Valve: When installing a plate heat exchanger, be sure to use a one-way valve in the water input (head), and always pay attention to the direction of the hot water and the cold water, as they must be in the opposite direction.

- Washing Principles: In addition to the necessity of installing a water softener (which has already been mentioned,) the installation of the spool nut and the valve on every port is mandatory in order for the washing service to perform periodic and acid washing.

- Manufacturer's catalog: The use of plate exchangers has become widespread in homes and industrial workshops. Therefore, it is very important to read the manufacturer's catalog before installing a plate heat exchanger in order to be able to benefit from your device.

Note: Due to the necessity of using a one-way valve and two strainers (filters) as well as a water softener (magnetic, electronic, etc.) during the installation and operation of all types of plate heat exchangers, make sure you also order those accessories and equipment along with your plate heat exchanger.

3. Finned Heat Exchanger

The type of finned heat exchangers is mainly used for "gas to gas" or "liquid to gas" applications, which are widely used in various industries, including refrigeration (even at very low temperatures), ducted/ductless air conditions, cold storage, energy recovery, process industries, and cold water coils.

These heat exchangers are also used in hot water coils of air conditioners, fan coils, hot water coils, unit heaters, etc. They are also used in gas turbines, nuclear power plants and propulsion engineering, refrigeration systems, heating and ventilation, excess heat recovery systems, and chemical industries.

How Finned Heat Exchanger Work

An air-cooled heat exchanger, like a car radiator or a condenser in split air conditioners or air-cooled chillers, uses airflow to cool a fluid (such as water or even gas). The operation of this type of heat exchanger is as follows:

Inside the heat exchanger, hot fluid (usually water or hot gas) enters from one side. This fluid contains heat that must be removed from it.

Fins in the heat exchanger surround tubes. These fins increase the heat transfer surface and increase the heat transfer efficiency. Air passes around the tubes and fins at high speed, and this air flow acts as a means of absorbing the heat of the hot fluid and cooling it.

As the air passes through the tubes and fins, the heat of the hot fluid is transferred to the air. The heat transfer from the fluid to the air passing over the coil is done in a better way by using the added surface of the fins.

As mentioned, with the help of fins, the level of heat transfer in the air-cooled heat exchanger is greatly increased, and this helps to cool the hot fluid better. This type of heat exchanger is used as an essential component in cooling engines and air conditioning systems, as well as in automobiles and many other devices and industries.

After transferring heat to the passing air, the hot fluid is cooled and exits from the other side of the heat exchanger. It is used to cool various systems, for example, in car engines to cool engine water.

Plate vs. Shell & Tube Heat Exchanger: Overall Comparison

In terms of comparison, plate heat exchangers may differ from shell & tube heat exchangers, which are presented in the following table:

|

|

Plate heat exchanger (gasketed) | Shell & Tube Heat Exchanger |

|---|---|---|

| Supply and return fittings | On the one hand | In several ways |

| coefficient of heat transfer | 3-5 | 1 |

| Working weight ratio | 1 | 3-10 |

| Dimensions | small | Big |

| space coefficient | 1 | 2-5 |

| Welding | NO | YES |

| Sensitivity to vibrations | not sensitive | is sensitive |

| Gasket | available on each page | Available in every BUNG |

| leakage detection | Easy | difficult |

| The possibility of access for inspection | No restrictions on any side | Limited |

| Disassembly time | up to 15 minutes | From 60 to 90 minutes |

| Repair | Replacement of plates or gaskets | Changing pipes or blocking pipes |

| Change in heat-transfer surface area | Easily by increasing and decreasing pages | difficult |

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

When choosing a heat exchanger required for the project, the type of heat exchanger, dimensions, as well as the material and working pressure, in addition to calculating and determining the capacity and heat level.

The important matter of the pressure drop of the water passing through the coil or plates of the heat exchanger (and air passing through the heat transfer coils) must be considered to calculate the head of the circulator pump or the static pressure of the ventilation fan.

Also, the correct calculation of the diameter of the water circulation pipes to all types of heat exchangers that the energy-carrying fluid is water causes the sufficient volume of the energy-carrying fluid to be able to carry out all the heat.

Causes of Plate Heat Exchanger Leakage and Perforation

Perforation of plate heat exchanger plates is one of the serious problems affecting the performance of heat transfer systems, as it leads to reduced efficiency and fluid leakage. This issue can be caused by several factors, which can be categorized as follows:

Below, we review the main causes of this phenomenon in a simple yet technical manner:

1. Pitting Corrosion

This is the most common cause of plate perforation in heat exchangers. When the fluid contains corrosive ions such as chlorides, these ions damage the protective layer of stainless steel and concentrate at a specific point. As a result, a very small pit forms, which rapidly penetrates the thickness of the exchanger plate and causes a leak.

2. Erosion Corrosion

When the fluid flow pressure exceeds the allowable limit, or when the fluid contains suspended particles such as sand, grit, or hard deposits, these particles act like abrasive materials. Over time, the thickness of the heat exchanger plate decreases in critical areas, eventually leading to perforation.

3. Cavitation Phenomenon

If the pressure drops significantly in certain sections of the heat exchanger, vapor bubbles are formed. When the pressure rises again, these bubbles collapse violently on the internal surface of the plate heat exchanger. These repeated impacts cause metal particles to detach and create microscopic holes in the inner walls of the plates.

4. Mechanical Stresses and Metal Fatigue

Sudden changes in temperature or pressure cause continuous expansion and contraction of the equipment and plates. Since plate heat exchanger plates are very thin (typically between 0.5 and 0.6 mm), these stresses lead to the formation of hairline cracks, which eventually result in metal perforation.

5. Scaling and Under-Deposit Corrosion

As is well known, changes in water temperature cause dissolved minerals to precipitate. Due to continuous temperature variations of the working fluids, heat exchangers are among the most scale-prone components in heat transfer systems. When a layer of scale forms on the internal surface of the plates, it not only reduces heat transfer efficiency but also creates an environment beneath it where fluid flow cannot reach. In these areas, the concentration of chemical substances increases, often leading to a severe type of corrosion known as crevice corrosion or under-deposit corrosion inside the heat exchanger plates, which gradually damages and destroys the plates.

6. Improper Installation and Maintenance

Excessive tightening or loosening of bolts can also apply uneven pressure on the plates of a plate heat exchanger, increasing mechanical stress and causing perforation, particularly around the bolt locations.

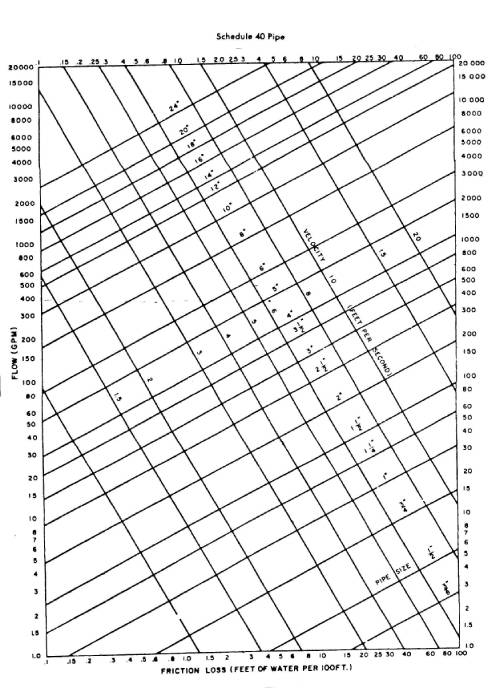

The Steel Pipe Diameter Calculation for the HVAC System

You can use the diagram below to calculate the diameter of steel pipes of heating and cooling systems:

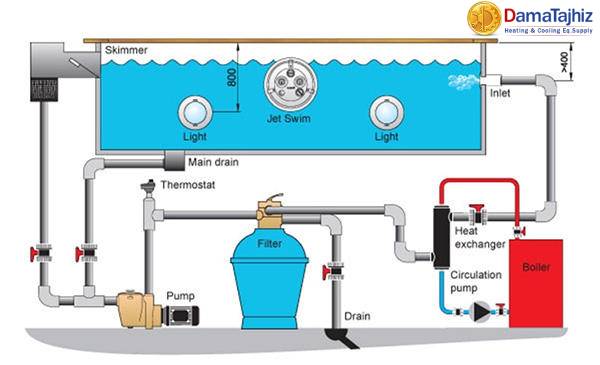

How to Place a Heat Exchanger in the Pool Heating System?

Due to the excessive usage of heat exchangers in swimming pools, saunas, and hot tub heating systems. The location of the heat exchangers as a pool heating system has been precisely determined in the image below, along with other pool equipment arrangements.

The usage of heat exchangers has been integrated due to the body material, which is usually made of steel or stainless steel. However, they should be carefully placed after the filter and before the disinfection equipment.

In the heat exchangers group of the DamaTajhiz HVAC website, which is the first and the most visited shopping site for cooling and heating devices in the Middle East. So feel free to browse and examine the product you truly desire, finalize your purchase at the most suitable price, and be sure of receiving original and valid service and guarantee.

Buying Heat Exchangers (Tube & shell / Plate)

To be able to buy the most efficient heat exchanger that will satisfy your needs, first determine the type and required capacity of the device.

On the DamaTajhiz HVAC website, the technical information of dozens of heat exchangers (plate and shell & tube) from reputed brands with their main guarantee has been presented for you to enjoy the good feeling of an optimal and smart purchase.

Also note that in the specialized HVAC group of Damatajhiz, all types of heat exchangers are only sold in bulk. Therefore, if you want to wholesale these products, contact us.

Heat Exchanger Price (Tube & Shell / Plate)

The price of the heat exchanger varies according to the variety of models and brands available on the DamaTajhiz HVAC website. Where you can discover the best deals on plate and shell & tube heat exchangers.

Our wide selection makes it easy for you to find the most suitable device for your needs.; it should be noted that the prices presented on the DamaTajhiz HVAC website are up-to-date, and a generous discount is already included in the prices. Therefore, the best price for all types of heat exchangers is guaranteed for wholesale purchase.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

Dear Users;

While thanking you for your trust in the technical opinions of the sales experts of DamaTajhiz HVAC Group, it should be mentioned that the determination and selection of the desired product brand based on history, brand strength, service, and product price is ultimately determined by the buyer.

However, in the case of heat exchangers, most users and buyers choose and purchase the best-selling brands such as Hepaco, Kaori, Agrin Energy, HTM, Azaran Sanat Amertat, and Aquamarine based on their quality, price, and after-sales services.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.