Control & Safety Valves

Control and safety valves are important in safely and optimally using fluids in HVAC equipment. The following content provides information on different models and brands, reviews, how to choose, and the prices of all control and safety valves.

Control and Safety Valve Expert Buying Guide and Price List

If you want to use control and safety valves and the fluid pressure differences, and you do not know what type of control and safety valve, what type of connection, brand, price, and specifications you need, stay with us as we answer all your questions.

In general, control and safety valves are equipment for controlling the flow and pressure of fluids. Control and safety valves are used in cases where there is a pressure difference in the fluid flow (both liquid and gas).

To select control and safety valves, in addition to considering the type of valve required (the most critical types of which are mentioned below), it is necessary to consider the size, type of connection (gear or flange), working temperature, working pressure, type of flow fluid, type of controllability, performance, body material, product brand, etc.

The Main Functions of Control and Safety Valves

These are some of the functions of the control and safety valve:

- Complete disconnection and connection of current

- Prevent the return of liquids and gases

- Adjust the passage of the required amount of liquids and gases

- Adjust and control the amount and pressure of liquids and gases

- Control and keep devices under pressure

Control and Safety Valves' Materials

The materials vary according to the type, application, working pressure, etc. cast iron, bronze, brass, and sometimes steel (SS) valves are commonly used in construction projects, while in industrial projects such as power plants, petrochemical plants, refineries, shipbuilding, the pharmaceutical/food industries, etc.

Depending on the fluid that passes through the valve or the environment, the body and other components can be carbon steel, alloy steel, and stainless steel.

Review, Selection, and Pricing of HVAC Equipment

Control and Safety Valves Categories

There are 3 main categories of control and safety valves:

- Manually operated valves

- Automatic valves that work with the air force, control valves, and gases (control valves)

- Electric motor-operated valves

Types of Safety Valves

Control and safety valves have the following types (which we will examine in the following):

- Diaphragm valves

- Two-way and three-way motorized valve

- Pressure-reducing valve

- Butterfly valves

- Safety valves

- Automatic valves

- Balancing valves

- Pressure relief valves

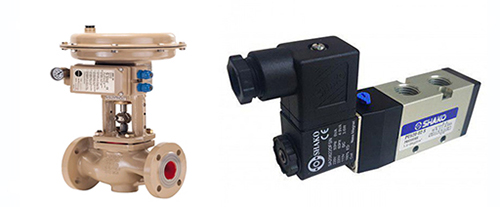

Automatic Valves (Solenoid Valves)

Automatic valves AKA solenoid valves are usually used with an automatic controller to control the amount of flow.

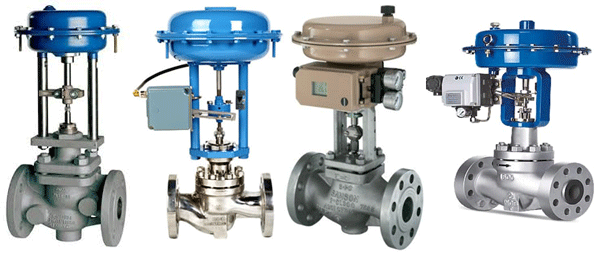

Types of Control Valves

Control valves are divided into the following groups:

Actuator Control Valves

An actuator control valve converts the output signal from the controller (electrical signal) into linear or rotational motion. Operators come in various sizes, types, outputs, and models.

The Most Common Actuators Used for Automatic Valves

6 most common actuators used in automatic valves are:

- Magnetic (mostly seen in solenoid valves)

- Pneumatic

- Electric

- Electronic

- Hydraulic

- Thermostatic

The radiator's thermostatic valve, with its air temperature sensor and the volumetric or longitudinal expansion of its actuator section (variable temperature), cuts off the radiator's hot water flow and maintains the room temperature balance.

Two-Way Valves (Single/Double Seat)

In two-way automatic valves, fluid enters the inlet and exits from the outlet. Depending on the valve stem position and the valve disc, current flows through the valve.

Two-way valves can have one or two seats. In the case of single-seat valves, a singular seat and a disc are used to close the valve.

Double-seat valves are two-way valves with two seats and two discs. These valves are used in cases where the pressure drop when closing the valve is required for two sections. Gradual, single-pulse, open normal, close regular, etc., are some examples of two-way automatic valves.

In some applications, these valves cannot be used due to the limited space or size of the existing 'mixing/dividing' three-way valves. In such cases, levers with two butterfly valves mounted on a three-way valve are used.

Note: The flow rates of butterfly valves differ from standard valves that have discs and seats, so using these valves is possible only in cases where their flow rates are compatible.

Three-Way Valves

In three-way valves, the two currents are mixed. They are commonly used in HVAC systems to mix hot and cold water. The application of these valves is to control the air temperature after cooling water coils.

So, the cold water in the coil is mixed with the hot water returning from the coil or the other way around.

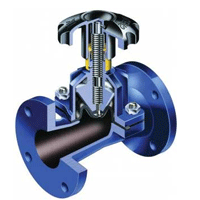

Diaphragm Valves

The diaphragm valves have a simple yet exciting structure. Diaphragm valves consist of three critical parts:

- Body

- Diaphragm

- Bonnet

The diaphragm is made of a reinforced rubber curtain or other elastic material that moves up and down by moving the handle of the elastic curtain valve and increasing/decreasing the fluid passage which controls the volume of fluid.

The diaphragm separates the valve contents from the opening and closing mechanism, so there is no need for sealing devices.

If material leaks around the valve, it indicates that the diaphragm is perforated and needs to be replaced. This type of valve is used to control corrosive substances such as acids.

Note: A diaphragm valve will be useless when the temperature is high because the diaphragm melts at high temperatures. Diaphragm valves are used only at low pressures and temperatures.

Pneumatic Valves

Control valves need a unique stimulus to start their activity. Some work with electric or hydraulic actuators, while others work with pneumatic actuators, which are used more than other valves in water or gas pipelines.

Pneumatic valves may be fully open or fully closed, or in other positions based on their user manual.

Pneumatic Valve Components

Pneumatic valves consist of 4 main parts:

- Control circuit

- Positioner (which adjusts valve mode and fluid flow rate)

- Mechanical valve (usually ball or butterfly type)

- Pneumatic power generator

Note: Pneumatic valves take some time to open and close, some of them are single-acting, and some are gradual and it is very important to consider the time that pneumatic valves need to open and close.

Pressure Reducing Valves

The pressure-reducing valve reduces the current fluctuations by reducing the pressure and keeping it at constant pressure.

The outlet pressure in the pressure-reducing valve is constant even when the inlet pressure fluctuates. Still, whenever it is required to adjust the outlet pressure, it is possible by using the upper handle of the valve.

This valve can be called a fully automatic device because it has a particular structure for making changes and reducing pressure, which does this without transferring energy. The water inlet pressure can also be adjusted using this valve, even when there are extensive inlet pressure fluctuations.

A pressure-reducing valve or pressure-regulating valve is usually installed near the water flow meter of buildings after branching from the main water pipe of the city.

These valves also have a unique screw for adjusting the pressure and regulating the valve's outlet pressure.

Pressure Relief Valves

Pressure relief valves are a type of safety valve that are usually used interchangeably. The appearance and function of both types of valves are the same, and it is to limit the amount of pressure of a liquid, vapor, or gas by discharging part of that fluid.

Safety valves are commonly used for air and steam. These valves are characterized by their rapid opening and closing. Pressure relief valves on the other hand are generally used for liquids, and they open or close slowly when the pressure changes.

Butterfly Valves

Butterfly valves are commonly used in oil and petrochemical units. Their structure has a typical body and a circular plate in the middle. The plate rotates around a bar at 90 degrees and connects to the valve's moving part. This actuator can be manual or by air pressure or electricity.

Butterfly valves are available in various sizes from 4 inches to 24 inches; They are easy to repair but must be lubricated regularly. In exceptional cases, some of them are equipped with a hand pulley connected to the plate's rotating rod, and its mechanism is located in a gearbox.

If the main drive, air or hydraulic, fails, they can hold the plate in any position by releasing it from the gear with a lever. The use of butterfly valves in units with low pressure during operation is widespread due to the minimal pressure drop.

Another feature of these valves is to maximize the fluid flow rate in the minimum time. Especially in fluid pressure control in tanks or towers, these types of valves are used to transfer fluids in large volumes.

Practical Advantages of Butterfly Valves

The following are some of the advantages of the butterfly valves:

- Easy to use

- No slippery and sliding parts

- Reduce pressure drop

- Ability to control

- Cheapness and lightness

Note: Do not combine the plate's fabric with porous chemical or petrochemical products as this might be very dangerous.

Butterfly Valves Applications

4 of the most common applications of the butterfly valves are:

- Thermal power stations

- Hydroelectric power stations

- Industries, especially oil and gas

- Water and sewage pipings

Balancing Valves

Manual balancing valves can be rotary (stem), ascending (rising), or non-ascending (non-rising).

Generally, the structure of this type of valve has a moving part with an orifice that adjusts its position according to the compressive forces and, thus, will change the flow passage area.

With this valve, when the pressure changes, the fluid flow will reach a predetermined value.

Safety Valves

Safety valves are a piece of special equipment that makes a unit safe against sudden pressure increases suitable for engine rooms, factories, and generally all industrial units and for different fluids such as gas, steam, water, or compressed air.

Pressure limitations in such applications, which usually result from the tolerable pressure of equipment, pipes, and devices or manufactured products, as well as problems related to maintaining the safety of people, are called safe operating limits for pressure or SOL / P.

How to open the safety valves and their working specifications are directly related to how the internal components of the safety valve are designed.

In most cases, this design is done so that after opening the safety valve due to pressure increase and the POP Action. This action is intensified quickly until the valve is fully returned.

Safety Valves Applications

Safety valves are used for gases, air, steam, etc. (except liquid). Safety valves automatically prevent an unauthorized increase in pressure relative to the defined and permissible pressure on pressure vessels and the piping system.

Safety valves automatically prevent excessive gas and liquid pressure. In other words, when necessary, the required amount of gas, steam, water, or air is discharged from reaching the permissible pressure of the device.

Types of Safety Valves

There are 3 main types of safety valves in terms of functionality:

- Safety valve with spring

- Weighted safety valves

- Safety valves with springs and diagrams

Safety valves are designed to open at a specific pressure. These valves are divided into three types:

- Safety valves installed on sources, tanks, and gas devices are called gas safety valves.

- Safety valves installed on sources and liquid devices are called liquid relief valves.

- Valves installed on gas and liquid sources and devices are called safety relief valves.

Buying Control and Safety Valves

Here at DamaTajhiz HVAC store, technical information and prices for all types of control and safety valves including water and fuel solenoid valves, motor valves, gas control valves, safety valves, steam valves, pressure relief valves, pneumatic valves, etc. from reputable brands such as Danfoss, Dangar, CSCase, Honeywell, Takban, Hisco, etc., have been presented for you to enjoy a good and smart shopping experience.

All products in the DamaTajhiz HVAC store come with the original warranty and the discounts desired by customers have already been included. If you have more questions about control and safety valves, you can contact us through email or WhatsApp.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet With You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.