DamaTajhiz Cooling Tower

DamaTajhiz cooling towers are manufactured and produced in open-circuit, closed-circuit, and industrial types with cubic and circular fiberglass models in terms of appearance and body material since 2004. The following content provides technical specifications, reviews, how to select, sales record, and the price for all models of DamaTajhiz Cooling towers.

DamaTajhiz Cooling Tower Expert Selecting Guide and Price List

In terms of temperature, the minimum temperature of the water exiting the cooling tower is usually a few degrees higher than the wet bulb temperature at the location of the cooling tower.

DamaTajhiz open-circuit, closed-circuit, and industrial fiberglass cooling towers with appropriate dimensions, sufficient thickness of the fiberglass body, the installation of the largest volume of packing inside the cooling tower to increase the cooling surfaces, as well as the use of new technology in the method of spraying and distributing water, have special advantages over other brands in terms of performance, efficiency, reducing water consumption and service.

Here at the DamaTajhiz HVAC store, technical information and the best prices for all types of DamaTajhiz cooling towers including cubic, circular, open-circuit, closed-circuit, and industrial cooling towers with the main warranty and fast delivery time have been presented for you to enjoy the good feeling of a smart shopping experience.

Factors to Consider When Buying a DamaTajhiz Cooling Tower

There are some very important factors you should keep in mind when buying a DamaTajhiz cooling tower including:

- Inlet water temperature to the cooling tower

- Outlet water temperature from the cooling tower

- Flow rate or volume of water entering the cooling tower

- Wet and dry air temperature of the cooling tower installation location

DamaTajhiz Industrial Cooling Towers

Industrial cooling towers constitute an important and extensive part of refrigeration equipment that is calculated, designed, and used in industries and manufacturing plants to maintain and provide the desired temperature range for the proper operation of production line equipment or the production of quality and optimal products in industrial processes.

The main distinguishing feature of industrial cooling towers is providing a temperature difference of more than 12 degrees Celsius between the inlet and outlet fluid and having special features and customization to meet the needs of the production process of each industrial project, which we will discuss below.

Why Choosing DamaTajhiz Industrial Cooling Towers?

It can be said that more than 60% of industries that use production lines and automation need refrigeration equipment to maintain high production volumes and stabilize the quality of their parts and products, and only 10 of these cases, which are food industries, are required to install chillers. Because of the need for temperatures lower than 20 degrees Celsius, which are generally included in food industries.

Therefore, other industries can choose industrial cooling towers to meet the refrigeration needs of their production lines at a much lower cost than installing chillers.

DamaTajhiz Industrial Cooling Tower Features

Among the important features of DamaTajhiz industrial cooling towers are:

- High efficiency in heat transfer.

- Providing a greater temperature difference than those cooling towers used in air conditioning systems.

- Change in design to reduce the need for periodic repairs.

- High accuracy and sensitivity in delivering the temperature and flow rate defined for the design and construction of industrial cooling towers.

- Differences in the types of internal elements such as using more resistant packings, anti-corrosive raw materials, reduced wear and tear of mechanical parts, etc.

- The ability to custom design industrial cooling towers for acidic and alkaline environments.

- No use of metal even as support inside and outside industrial cooling towers.

- Definition and adaptation of each tower to the intended project's specific temperature and weather conditions.

Types of DamaTajhiz Industrial Cooling Towers

There are two main types of DamaTajhiz industrial cooling towers open-circuit and closed-circuit:

DamaTajhiz Open-Circuit Industrial Cooling Tower

DamaTajhiz open-circuit industrial cooling towers are those where the incoming water goes directly to the main consumer after coming into contact with the air and reducing its temperature, such as a condenser or production equipment.

DamaTajhiz open-circuit industrial cooling towers are used in various places such as:

- Parts manufacturing industries are used to cool down machinery.

- Metal and plastic injection industries for cooling down the mold bodies.

- Disposable containers for cooling mold bodies and the desired quality of parts.

- Leather manufacturing industries for the quality of the final product.

- Dairy industries for rapid cooling of packaged products.

- Isogam manufacturing industries for increasing production and the desired quality of the product during the working season.

- Textile industries for increasing the quality of manufactured products.

- All sectors of the automotive industry that have production lines and where the speed and quality of production are important.

DamaTajhiz Closed-Circuit Industrial Cooling Tower

DamaTajhiz closed-circuit industrial cooling towers are those where the water inside the tower does not enter the equipment or condensers directly are called closed-circuit cooling towers.

In these towers, by installing a coil inside the tower and cooling the intermediate fluid that flows inside the coil (usually water), the fluid is sent from the temperature drop into the production line equipment.

DamaTajhiz Industrial Cooling Tower Buying Guide

To determine the capacity and buy a suitable DamaTajhiz industrial cooling tower, the following basic information is required:

- Desirable temperature of the mold, process, or manufactured products.

- The time it takes for the cooling fluid temperature to reach the desired temperature after starting the production line.

- The heating rate of the injection devices or the volume of required cooling water.

- The geographical location of the installation site in terms of outside temperature and relative humidity in summer.

- The number of machinery in the production line.

For Example:

Production of small disposable parts in a hot climate using 3 injection molding machines, including one 100-gram machine and two 200-gram machines with a coolant volume of approximately 600 liters, reaches a hot temperature within an hour and a half after starting work in the summer, which causes damage to the manufactured parts. The desired production temperature is 40 degrees.

Cooling Down Plastic and Metal Mold Injection Machinery

One of the most important reasons for cooling devices in industries is to cool plastic and metal injection molds to maintain the quality of parts and molds in the production line.

Unfortunately, some people, especially sellers of injection molding machines, consider the use of chillers to cool injection molds and recommend the installation of chillers to buyers.

Mold injection machines that work at high temperatures do not require the temperature of the cold water of the chiller to form the part and prepare for the next injection. As you might know, the temperature of all production molds and their cooling fluid in normal and continuous production is in the range of 35 degrees to 90 degrees Celsius.

As the operators and owners of these machines know, by reducing the temperature of the mold (intermediate fluid) by 10 to 15 degrees Celsius, the quality of the final product is maintained and the manufacturer can increase the number of parts produced without waiting for the mold to cool.

Therefore, using an expensive and complex device with sensitive parts such as a chiller with a high initial purchase cost and astronomical electricity consumption to cool the temperature of the production line fluid has many disadvantages, such as:

- They have high electricity consumption costs.

- Chillers impose a high initial cost on the buyer.

- The cost of repairing and maintaining chillers is very high due to having precise and foreign parts.

- Chiller repairs are a difficult and complex task that requires a skilled expert.

- Chillers are easily damaged with the slightest changes and are removed from the production line.

Answer and Solution:

Using an industrial cooling tower instead of a chiller can be a suitable and inexpensive solution for cooling all mold injection machines and other production machinery.

We as the designers and producers of cooling towers since 2004 highly emphasize the use of industrial cooling towers instead of chillers in factories and workshops because of the following reasons:

- Much lower cost of an industrial cooling tower compared to a chiller

- There is only one moving electrical and one mechanical part in industrial cooling towers, the electromotor and the reducer.

- Cooling towers can work without the need for skilled people for repairs or any semi-skilled labor.

- Unlike chillers, cooling towers work without the need for environmental concerns such as freezing.

- Very low cost of replacing parts and ease of obtaining spare parts compared to chillers.

- Creating a temperature difference of 10 degrees to 15 degrees Celsius in proportion to the ambient temperature.

- Very low power consumption compared to a chiller, at the level of a few horsepower electric motor!

DamaTajhiz HVAC Co.; Engineering, Manufacturing, and Trading Company in the Middle East Since 2004

Review, Selection, and Pricing of HVAC Equipment

DamaTajhiz Closed-Circuit Cooling Towers

First of all, it should be noted that closed-circuit cooling towers are used to separate the water inside the cooling tower from the water inside the condenser or inside industrial equipment.

DamaTajhiz close-circuit cooling towers are used in industrial processes in which production line equipment is sensitive to temperature, both in terms of maintaining the continuity of operations and production line equipment and sometimes even in terms of reducing the temperature of the product during the production process.

In closed-circuit cooling towers, coils are installed to separate the water inside the cooling tower, which is saturated with sediment and salt due to contact with the outside air and heat exchange. In this way, the intermediate fluid in the coil is cooled and protected from tower water sediments and further damage.

The coils are made of copper due to their high heat transfer conductivity, and in some cases, they are made of stainless steel at the request of the customer. All coils are tubular, and a collector is placed in the form of a small tank at the beginning or end of the tubes to accumulate or change the direction of the fluid inside the coil.

Because it is expensive to build a circular heat exchange coil, closed-circuit cooling towers are all built in a cubic shape. The cubic design also allows the coil to be mobile for repairs and maintenance, which is very important. Therefore, closed-circuit towers are necessarily cubic.

Closed-circuit cooling towers are used in various productions such as glassmaking, food products (soft drinks, fruit juices, etc.), the production of plastic parts, die-casting and metal parts, rubber manufacturing, and wherever the financial value of the production lines and production equipment is worth this cost.

The design of the DamaTajhiz closed-circuit cooling towers is done according to specific calculations, which are based on initial information and data from the customer, as well as the temperature conditions of the production process and the installation location of the cooling tower.

The Structure of DamaTajhiz Closed-Circuit Cooling Towers

DamaTajhiz close-circuit cooling towers include a tubular coil, coil support, fluid inlet, and outlet flange to the coil, and also an electro pump that regulates the speed of water or fluid inside the coil, which will be determined and specified by DamaTajhiz based on the temperature calculations of the process.

Engineer Design and Construction Calculations of the DamaTajhiz Closed-Circuit Cooling Towers

Many calculations must be done considering the following factors and requirements:

- Calculation of the required heat exchange capacity in the coil.

- Determination of heat exchange surfaces and number of tubes and coil dimensions.

- Number of rows and how the tubes are placed (density).

- Determination of the heat exchange capacity in the open-circuit cooling towers in proportion to the required cooling of the coil in environmental conditions.

- Determination of the tower dimensions in proportion to the determined coil dimensions, especially the height.

- Determination of the airflow and water flow of open-circuit cooling towers for the required heat exchange in the coil.

- Determination of the fluid circulator pump inside the coil in proportion to the flow rate and design conditions for heat exchange.

- Internal technical designs of the cooling tower including base, coil, nozzles, etc.

Unfortunately, some companies simplify the determination of capacity and the need for accurate calculations before producing a closed-circuit cooling tower and present their proposal without taking into account sufficient technical information such as flow rate, capacity, and ambient temperature.

For example:

For a project where the flow rate of the intermediate fluid is about 350 GPM (equivalent to the flow rate of a 100-ton open-circuit cooling tower), a 100-ton closed-circuit tower is recommended, which means placing a coil in a regular 100-ton cooling tower.

Basic Information Required to Design a DamaTajhiz Closed-Circuit Cooling Tower

There are a few basic pieces of information required for designing a DamaTajhiz close-circuit cooling tower:

- Required Water Flow Rate: In other words, the total volume of liquids used to cool the devices.

- Maximum Temperature of the Intermediate Fluid: What is the maximum temperature that the intermediate fluid that enters the equipment reaches before this heat prevents the continuation of production?

For example, The cooling water of 3 plastic injection machines reaches 50 degrees after starting work in June and after 2 hours of work. And after 4 hours it reaches 75 degrees and the device needs to be shutted off! - Production Temperature: In simple terms, what is the appropriate temperature of the intermediate water for optimal operation of the equipment?

Usually, operators and employers of production lines specify a temperature range, and it is better to consider the minimum temperature during design. - Ambient Temperature and Relative Humidity: Relative humidity of the air and maximum and minimum summer temperatures in the installation location and seasonality operation or full-time operation.

Factors to Consider When Buying a DamaTajhiz Fiberglass Cooling Tower

When buying a DamaTajhiz fiberglass cooling tower, you should keep in mind the following factors:

- Since cooling towers are located in open environments and exposed to direct sunlight, a suitable coating of Neopentyl Glycol (NPG) is used in the body of DamaTajhiz fiberglass cooling towers to protect the body of the cooling tower against ultraviolet rays.

- Considering that all internal parts of the cooling tower are always in direct contact with water, all main metal parts such as the structure and auxiliary parts of DamaTajhiz fiberglass cooling towers (screws, nuts, etc.) are produced from stainless steel or galvanized iron to prevent rusting and decay.

- The water cooling surfaces (packings/fills) inside the DamaTajhiz cooling towers are selected from the appropriate designs and materials. Usually from P.V.C with a special antibacterial coating of medical grade (FDA approval) with a thickness of 400 microns and a splash or random-splash packing made of PP which is supplied according to the choice and order of the customer.

- To choose the right packing/fill for the cooling tower, pay attention to the use and operating conditions of the device; for example, the plate-shaped packings (fills) that are made of PVC are more efficient than the splash packings that are made of PP due to the creation of a wider contact surface between the water and the air, but in contrast, the splash packings are more resistant to sediment and poor-quality water (hard water) and are more susceptible to clogging and erosion.

- The eliminator or drip catcher is usually made of PVC or PP and is installed at the top of the nozzles to reduce the amount of drift or water droplets from the top of the cooling tower. The design of the PVC eliminator is usually a honeycomb shape and in PP models it is a V-bar shape, which reduces the amount of water loss to the minimum possible and less than 0.002 water in the cooling tower circulation.

- To increase the life of the electric motor and reduce the noise of the air fan when starting up the cooling towers, ensure the static and dynamic balance of the air circulation fan.

- When ordering cooling towers with high capacities, it is better to use a power transmission system equipped with a gearbox.

- Ladders are usually installed for easy access to various parts of the cooling tower as well as maintenance and repair.

- In air conditioning systems, the temperature of the water entering the cooling tower (from the condenser of the water-cooled chiller) is about 33 to 35 degrees Celsius, and the temperature of the water leaving the cooling tower to the condenser of the water-cooled chillers should be about 28 to 30 degrees Celsius. In other words, the temperature difference between the water entering and leaving the cooling tower in air conditioning systems is usually about 4 to 6 degrees Celsius.

- In closed-circuit cooling towers, which are usually used for some industrial and cooling operations, the cooled water is used to reduce the temperature of the fluid passing through the coil inside the tower.

- If a smart control system is not installed, a thermostat must be used instead in the return water path from the cooling tower to the cooling tower pump collector to control the temperature of the water leaving the device, with the ability to turn on and off the cooling tower ventilation fan automatically.

DamaTajhiz HVAC Co. is one of the most reputable manufacturers of various air conditioning equipment with the best quality in the Middle East and West Asia since 2004.

Using the most advanced and fully automatic industrial machinery and relying on the knowledge and expertise of colleagues who have completed all training courses, based on engineering calculations to manufacture and supply a wide range of products such as:

- Cooling Towers: Open/closed-circuit, industrial, circular, cubic, fiberglass, and galvanized cooling towers from 10 to 800 tons of refrigeration.

- Chillers: Water/air-cooled, scroll, and screw compression chillers.

- Mini Chillers: Water/air-cooled mini chillers from 3 to 15 tons of refrgeration.

- Air Conditioners: Domestic, industrial, and hygienic air conditioners as well as ducted split AC units from 2 to 5 tons of refrigeration.

- Air Washers: All types of air washers in all capacities.

- Fan Coil Units: Fan coil units in all sizes and capacities.

- Industrial Evaporative Coolers: Industrial swamp coolers in various capacities.

- Exhaust and Ventilation Fans: Centrifugal and axial fans.

- Etc.

Note: It is possible to visit the factory during the production stages and if you need further advice on selecting the right cooling tower, you can contact the DamaTajhiz HVAC sales team.

Extra: Each ton of refrigeration equals 12,000 BUT per hour

- Damatajhiz Engineering Company is one of the most reputable manufacturers of various HVAC equipment with top-quality standards in Iran and Middle Eastern countries. Since 2004, the company has been producing and supplying a wide range of products, including open-circuit, closed-circuit, and industrial cooling towers in round and cubic designs made of fiberglass and galvanized steel, with capacities ranging from 10 to 800 refrigeration tons, equivalent to 120,000 to 9,600,000 BTU. Its product portfolio also includes water-cooled and air-cooled compression chillers (scroll and screw types), various industrial and hygienic air handling units with different capacities, air washers, different types of fan coil units, air-cooled mini chillers with capacities from 3 to 15 refrigeration tons, ducted split AC units with capacities from 2 to 5 refrigeration tons, industrial evaporative coolers, exhaust fans, ventilation fans, and more. All products are manufactured using the most advanced fully automatic industrial machinery and supported by the expertise and technical knowledge of well-trained professionals, based on precise engineering calculations and tailored to the specific conditions of each project. Damatajhiz also offers a golden product warranty, competitive pricing, and the opportunity to visit the factory during the production stage.

"Mr. Asaad Kazem Project (Shipment of 5 cubic fiberglass cooling towers with a capacity of 300 refrigeration tons from Damatajhiz to Iraq)"

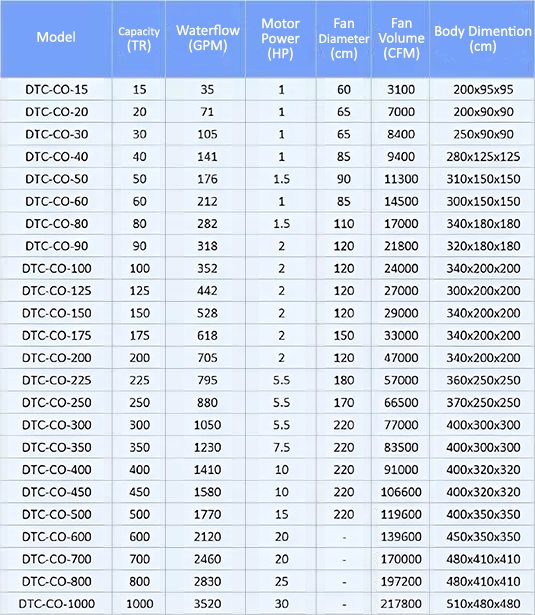

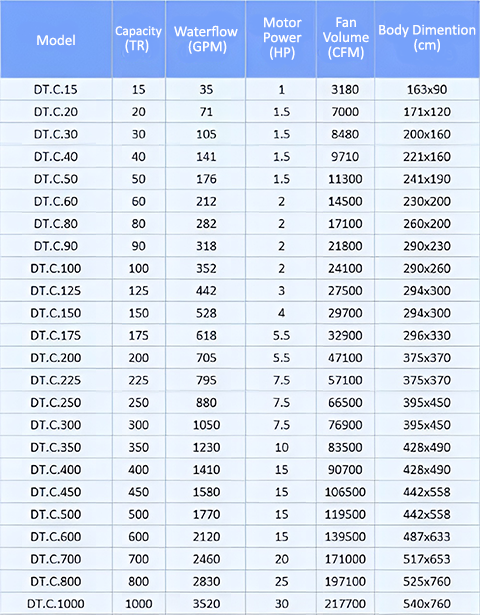

DamaTajhiz Cooling Tower Technical Specifications Table

The following table presents the most important technical specifications for DamaTajhiz fiberglass cooling towers:

DamaTajhiz Open-Circuit Cubic Fiberglass Cooling Towers (DTC-CO Series):

DamaTajhiz Open-Circuit Circular Fiberglass Cooling Towers (DT.C Series):

Buying DamaTajhiz Cooling Towers

The first step in buying a Damatajhiz cooling tower is to determine the capacity and the dimensions of the installation location of the device. DamaTajhiz cooling towers are manufactured and supplied in different types with different capacities, dimensions, and uses.

So it is very important to consider the flow rate and volume of water and the use of your environment, then factors like the temperature difference, features, brand, and type of cooling tower to make sure the right model and capacity are selected.

Here at the DamaTajhiz HVAC store technical information on all types and models of DamaTajhiz cooling towers with original warranties is provided for you to enjoy an optimal and smart shopping experience.

The Price of DamaTajhiz Cooling Towers

The price of DamaTajhiz cooling towers varies based on the type and capacity. So you must first determine the required cooling tower's type and capacity.

All the DamaTajhiz cooling towers presented in the DamaTajhiz HVAC store have product identifiers and reasonable prices, and the discounts desired by consumers have already been included in these prices.

Note: To inquire about the price of a cooling tower, in addition to stating the required circulating water flow rate, and the temperature of the water entering and leaving the device, you must also specify the geographical installation location of the cooling tower, the type, and the body material of the device.

DamaTajhiz Cooling Tower Top Buyers

While thanking all our dear customers, here's the list of the top 126 buyers of the DamaTajhiz Cooling Towers:

- Mr. Asaad Kazem (Project in Iraq): 5 units of Damatajhiz cubic fiberglass cooling towers with a capacity of 300 refrigeration tons

- Hamrah Aval Administration Project: 2 units of Damatajhiz cubic fiberglass cooling towers with a capacity of 150 refrigeration tons

- Tadbir Saze Faramān Company (Kermanshah Governorate Project): 3 units of Damatajhiz cubic fiberglass cooling towers with a capacity of 250 refrigeration tons

- Behdasht Chemical Company Project: 3 units of Damatajhiz cubic fiberglass cooling towers with capacities of 100 and 300 refrigeration tons

- Shahid Ghazi Pharmaceutical Company: 800-ton refrigeration capacity cubic fiberglass cooling tower (two-cell) by Damatajhiz.

- Tam Tejarat Tavana Company Project: 60-ton DamaTajhiz cubic fiberglass cooling tower

- Engineer Madadi’s Project: Two DamaTajhiz cubic fiberglass cooling towers with a capacity of 150 tons

- Zar Spring Manufacturing Company (Saipa): 200-ton DamaTajhiz cubic fiberglass cooling tower

- Mr. Javaheri - Shalamcheh: 2 DamaTajhiz 200-ton cubic fiberglass cooling towers.

- Dejpa Oil and Bitumen Refining Company: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Vista Sanat Tojal Company: 1 DamaTajhiz 180-ton double-cell cubic fiberglass cooling tower.

- Alvand Tile and Ceramic Company: 200-ton cubic fiberglass cooling tower, refrigeration temperature equipment

- Fahim Food Industries Company: 1 DamaTajhiz 300-ton cubic fiberglass cooling tower.

- Shazand Petrochemical Company: 3 DamaTajhiz 200-ton cubic fiberglass cooling towers.

- Semnan Chemical Energy Company: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower.

- Sadr Bridge Residential Complex - Tehran Qalandari Street: 1 DamaTajhiz 125-ton cubic fiberglass cooling tower.

- Fara Daru Fan Avar Mehr Company: 1 DamaTajhiz 40-ton cubic fiberglass cooling tower.

- Eram Grand Hotel - Tehran: 2 DamaTajhiz 150-ton cubic fiberglass cooling tower.

- Mr. Ebrahim Sherahi: 1 DamaTajhiz 40-ton cubic fiberglass cooling tower.

- Ghot Arvand Company: 1 DamaTajhiz 30-ton cubic fiberglass cooling tower.

- Yazd Hadid Steel Company: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Mr. Asadi - Tehran, Niavaran: 1 DamaTajhiz 30-ton cubic fiberglass cooling tower.

- Telecommunications - Tehran, District 2: 1 DamaTajhiz 80-ton cubic fiberglass cooling tower.

- Naqshineh Steel Company - Tabriz: 1 DamaTajhiz 40-ton cubic fiberglass cooling tower.

- Mr. Sherahi - Shahr-e-Ray: 1 DamaTajhiz 40-ton cubic fiberglass cooling tower.

- Baikem Kimia: 2 DamaTajhiz 400-ton cubic fiberglass cooling towers.

- Mr. Ghobishawi: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Mr. Fattalpour: 1 DamaTajhiz 60-ton cubic fiberglass cooling tower.

- Mr. Khodai: 1 DamaTajhiz 20-ton cubic fiberglass cooling tower.

- Roshd Plast Company: 1 DamaTajhiz 60-ton cubic fiberglass cooling tower.

- Pars Molybden Company: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower.

- Afaq Gostaral Company: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Rahyab Khak Ebniye Company: 1 DamaTajhiz 60-ton cubic fiberglass cooling tower.

- Robat Ferroalloy Complex - Kerman: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Mehr Afshan Chemical Company: 1 DamaTajhiz 20-ton fiberglass cooling tower.

- Shahid Beheshti University: 1 DamaTajhiz 20-ton cubic fiberglass cooling tower.

- Kara Andisheh Hammers Company: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Jahan Alek Afra Company: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower.

- Mr. Zare: 1 DamaTajhiz 20-ton cubic fiberglass cooling tower.

- Mr. Beigi: 1 DamaTajhiz 40-ton cubic fiberglass cooling tower.

- Kimia Tak Razi Arvand Company: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Arg Jadid Travel Agency: 1 DamaTajhiz 60-ton cubic fiberglass cooling tower.

- Sandan Iranian Industries Company: 1 DamaTajhiz 80-ton cubic fiberglass cooling tower.

- Mr. Khodakarami: 1 DamaTajhiz 150-ton cubic fiberglass cooling tower.

- Mr. Sharifi: 1 DamaTajhiz 80-ton cubic fiberglass cooling tower.

- Afshan Shimi Mehr Company: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Iman Tek Tabarestan Company: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Golnan Company: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower.

- Liosa Pharmed Company - Tehran: 1 DamaTajhiz 20-ton cubic fiberglass cooling tower.

- Mr. Aibakabadi - Iraq: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Copal Aluminum Company - Isfahan: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Sepehr Gostar Oil Industries Company - Arak: 1 DamaTajhiz 40-ton cubic fiberglass cooling tower.

- Parisan Ventilation Company - Kerman: 2 DamaTajhiz cubic fiberglass cooling tower.

- Firoz Residential Complex - Mashhad: 2 DamaTajhiz cubic fiberglass cooling tower.

- Electricity of Sistan-o-Baluchestan, District E: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Iran Khodro Aluminum Casting Company - Abhar: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Zahedan Governorate - Zahedan: 1 DamaTajhiz 60-ton cubic fiberglass cooling tower.

- Misagh Farm: 1 DamaTajhiz 20-tons of cubic fiberglass cooling tower, temperature-controlled refrigeration

- Tepco Energy Company: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Aramco Tehran Company - Tehran: 1 DamaTajhiz 40-ton cubic fiberglass cooling tower.

- Setareh Caldon Company: 1 DamaTajhiz 800-ton cubic fiberglass cooling tower.

- Buali University - Hamadan: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower.

- Fateh Polymer Company - Shiraz: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower.

- Pars Polymer Khavaran Company: 1 DamaTajhiz 60-ton cubic fiberglass cooling tower.

- Melika Dairy Company - Karaj: 1 DamaTajhiz 350-ton cubic fiberglass cooling tower.

- Karmania Automotive - Bam: 1 DamaTajhiz 80-ton cubic fiberglass cooling tower.

- Crop Iran Company - Qazvin: 1 DamaTajhiz 150-ton cubic fiberglass cooling tower.

- Kashan Ductile Pipe Company Kashan: 1 DamaTajhiz 400-ton cubic fiberglass cooling tower.

- Karan Company - Qum, Pouyan Steel: 1 DamaTajhiz 80-ton cubic fiberglass cooling tower.

- Tehran University of Science and Technology - Tehran: 1 DamaTajhiz 20-ton cubic fiberglass cooling tower.

- NAJA Central Command Headquarters: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Khorjin Gostar Company - Arak: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Refractory Materials Supply and Production Company: 1 DamaTajhiz 120-ton cubic fiberglass cooling tower.

- Nano Age Knowledge Company: 1 DamaTajhiz 300-ton cubic fiberglass cooling tower.

- Sabalan Fabric Company - Ardabil: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Tehran Battery Power Company - Tehran: 1 DamaTajhiz 500-ton cubic fiberglass cooling tower.

- Parmida Zafaranieh Project - Tehran: 1 DamaTajhiz 170-ton cubic fiberglass cooling tower.

- Mohned Keshavarz Project - Shiraz: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower.

- Dina Power Development Company: 1 DamaTajhiz 60-ton cubic fiberglass cooling tower.

- Mehr Steel Company - Sahand: 2 DamaTajhiz 60-ton cubic fiberglass cooling tower.

- Behnoosh Company - Tehran: 2 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Abhar Aluminum Casting Company: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Amrabadi Engineer Project - Isfahan: 1 DamaTajhiz 30-ton cubic fiberglass cooling tower.

- West Asia Cement Company - Mashhad: 1 DamaTajhiz 250-ton cubic fiberglass cooling tower.

- Qazvin Aluminum Rolling Company - Qazvin: 1 DamaTajhiz 200-ton cubic fiberglass cooling tower.

- Sarban Sanat Sabz Company - Mazandaran: 1 DamaTajhiz 80-ton cubic fiberglass cooling tower.

- Derakhshan Co. - Iraq, Shimi Bandar: 1 DamaTajhiz 150-ton cubic fiberglass cooling tower.

- Asadi Engineer Project - Kerman: 2 DamaTajhiz 700-ton cubic fiberglass cooling towers.

- Zarbaft Farahan Factory - Tabriz: 2 DamaTajhiz 200-ton cubic fiberglass cooling towers.

- Hamon Naizeh Factory: 4 DamaTajhiz 100, 200, 250, and 400-ton cube fiberglass cooling towers.

- Mr. Shafiei - Tehran: 1 DamaTajhiz 150-ton cubic fiberglass cooling tower.

- Yekta Tahrir Indica Company Factory - Sirjan: 1 DamaTajhiz 30-ton cubic fiberglass cooling tower.

- Iran Bronze Steel Company - Tehran: 2 DamaTajhiz 50-ton cubic fiberglass cooling tower.

- Anoushirvan Niavaran Residential - Tehran: 1 DamaTajhiz 150-ton cubic fiberglass cooling tower.

- Mr. Abdolmohammadi - Tehran, Zafaraniyeh: 1 DamaTajhiz 250-ton cubic fiberglass cooling tower.

- Setareh Caspian International Food Industries: 1 DamaTajhiz 400-ton cubic fiberglass cooling tower.

- Anbieh Gostar Company - Shahrood: 2 DamaTajhiz 175-ton cubic fiberglass cooling towers.

- Mr. Zakeri - Jafatai: 1 DamaTajhiz 250-ton cubic fiberglass cooling tower.

- Kia Electromotor Part Company - Safadasht, Industrial Park: 1 DamaTajhiz 150-ton cubic fiberglass cooling tower.

- Behshir Najm Hessam Company / Sepehr Industrial Park - Nazarabad: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower.

- NAJA Headquarters: 1 DamaTajhiz 300-ton circular fiberglass cooling tower.

- Sadaf Gostar Co.: 1 DamaTajhiz 50-ton circular fiberglass cooling tower.

- Tehran Delta Co.: 1 DamaTajhiz 250-ton circular fiberglass cooling tower.

- Mahan Aviation Co.: 1 DamaTajhiz 90-ton circular fiberglass cooling tower.

- Mena Polymer Company: 1 DamaTajhiz 160-ton circular fiberglass cooling tower.

- Ama Fuel Company: 1 DamaTajhiz 60-ton circular fiberglass cooling tower.

- Yazd Baft Company - Yazd: 1 DamaTajhiz 175-ton circular fiberglass cooling tower.

- Iran Language Center: 1 DamaTajhiz 125-ton circular fiberglass cooling tower.

- Yak-Yak Company: 1 DamaTajhiz 150-ton circular fiberglass cooling tower.

- Pars Khazar Company: 1 DamaTajhiz 100-ton circular fiberglass cooling tower.

- Sam Electric Company: 1 DamaTajhiz 150-ton circular fiberglass cooling tower.

- Najafabad Azad University - Najafabad: 1 DamaTajhiz 300-ton circular fiberglass cooling tower.

- Mr. Baharan Shimi - Borujen: 1 DamaTajhiz 125-ton circular fiberglass cooling tower.

- Ferdowsi University - Mashhad: 1 DamaTajhiz 30-ton circular fiberglass cooling tower.

- Mr. Peykar Ara: 1 DamaTajhiz 100-ton circular fiberglass cooling tower.

- Meditec Sys Company: 1 DamaTajhiz 100-ton circular fiberglass cooling tower.

- Yazd Wire and Cable Company: 1 DamaTajhiz 100-ton circular fiberglass cooling tower.

- Tehran Azad University - Tehran: 1 DamaTajhiz 125-ton circular fiberglass cooling tower.

- Al-Faisal Project - Morocco: 1 DamaTajhiz 50-ton circular fiberglass cooling tower.

- Izogam Shargh Donya Company: 1 DamaTajhiz 400-ton circular fiberglass cooling tower.

- Saipa Construction: 1 DamaTajhiz 400-ton circular fiberglass cooling tower.

- Jihad University of Science and Technology: 1 DamaTajhiz 60-ton circular fiberglass cooling tower.

- Kashan University of Medical Sciences - Kashan: 1 DamaTajhiz 175-ton circular fiberglass cooling tower.

- Al-Faisal - UAE: 1 DamaTajhiz 60-ton circular fiberglass cooling tower.

- Refractory Materials Supply and Production: 1 DamaTajhiz 120-ton circular fiberglass cooling tower.

- Mihanzaj Company: 1 DamaTajhiz 450-ton circular fiberglass cooling tower.

- Tehran University - Boys' Dormitory: 1 DamaTajhiz 150-ton circular fiberglass cooling tower.

- Tehran University - Girls' Dormitory: 1 DamaTajhiz 150-ton circular fiberglass cooling tower.

- Khorasan Razavi Audio and Video: 1 DamaTajhiz 150-ton circular fiberglass cooling tower.

- Khorasan Electric Industries Company: 1 DamaTajhiz 100-ton circular fiberglass cooling tower.

- Tehran Oil Exploration Operations Company: 1 DamaTajhiz 200-ton circular fiberglass cooling tower.

- Iran Helicopter Manufacturing Company (Penha): 1 DamaTajhiz 250-ton circular fiberglass cooling tower.

- Engineer Nazari - Tehran, Niavaran: 1 DamaTajhiz 150-ton circular fiberglass cooling tower.

- Engineer Mardani - Tehran, Sa'adat Abad: 1 DamaTajhiz 170-ton circular fiberglass cooling tower.

Note: You can visit the projects after coordinating with the DamaTajhiz HVAC.

________________________________________________________________________

"Mr. Asaad Kazem – Iraq Project (Shipment of 5 cubic fiberglass cooling towers with a capacity of 300 refrigeration tons from Damatajhiz to Iraq)"________________________________________________________________________

"MCI Project (2 Cubic Cooling Towers, 150 Ton Refrigeration – DamaTejhiz)"

________________________________________________________________________

"Engineer Javaheri - Shalmcheh: 2 DamaTajhiz 200-ton cubic fiberglass cooling tower."

______________________________________________________________________

"Yekta Tahrir Indica Factory - Sirjany: DamaTajhiz 30-ton cubic fiberglass cooling tower."

________________________________________________________________________

"Najm Hossam Company (Sepehar Nazarabad Industrial Estate) - Behshir: 1 DamaTajhiz 100-ton cubic fiberglass cooling tower."

________________________________________________________________________

"Engineer Shafiei - Tehran, Pasdaran: 1 DamaTajhiz 150-ton fiberglass cooling tower."

________________________________________________________________________

"Engineer Zakari - Joghtai city: 1 DamaTajhiz 250-ton fiberglass cooling tower."

________________________________________________________________________

"Other Projects Equipped with Different Types and Capacities of DamaTajhiz Cooling Towers"

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.