Boiler Burner

The burner, together with the boiler, forms the heart of a building’s central heating system. Below, the types of burners, technical specifications, capacity sizing, selection criteria, and the best purchase prices of burners are presented.

Boiler Burner Expert Selection Guide and Price List

Generally, a boiler burner, also known as a burner boiler, is a device that converts fossil fuel energy into thermal energy by burning it. The energy generated by the burner for a boiler in the boiler's combustion chamber is transferred to the energy-transferring fluid (water in most cases) by displacement and radiation methods.

Boiler burners create heat in all relevant types of boilers and heaters. They are known as the beating heart of the heating systems.

Review, Selection, and Pricing of HVAC Equipment

A burner operates by atomizing or injecting fuel (gas, diesel oil, or heavy fuel oil) and mixing it with air. This fuel–air mixture passes through a diffuser (flame spreader) and is then ignited by the ignition transformer and spark electrodes. This combustion process generates the required heat inside the boiler or furnace combustion chamber.

It should be noted that every burner and boiler includes several control devices—such as the relay, photocell, pressure switch, and solenoid valve—which regulate the amount and timing of each stage of the burner operation.

Optimal burner performance has a significant impact on improving the combustion process, reducing energy consumption, and ensuring proper operation of mechanical systems. Therefore, by using the technical information provided by DamaTajhiz’s specialized platform, you will be able to select the best and most efficient heating equipment suitable for your project.

4 Points about Boiler Burners Fuel Combustion

The following are four of the most important points about the fuel combustion of a boiler burner:

- For every 300-meter increase in height above the sea level (due to the decrease in air density), the fuel combustion efficiency of all types of boiler burners decreases by about 4%.

- The calorific value of each cubic meter of natural gas is approximately equivalent to 9200 kcal.

- The calorific value of each liter of diesel is approximately equivalent to 8500 kcal/h.

- The calorific value of each kilogram of diesel is approximately equivalent to 10500 kcal/h.

Note: To choose a boiler burner, after determining the type of fuel and its suitable capacity, pay attention to the diameter of the boiler burner's flame tube for the possibility of placing it in the boiler. Do not forget that you can always consult with the experts of DamaTajhiz company about it.

Types of Boiler Burners

Mainly, there are three types of boiler burners based on the fuel they burn, which are "Gas-Fuel Boiler Burners", "Liquid-Fuel Boiler Burners", and "Dual-Fuel Boiler Burners". In the following, you study all three types in detail. After that, you can compare them to select the best one for you.

Gas Boiler Burner

Gas boiler burners are divided into two types: those with a fan (or blowers) and those without one, which makes them completely noiseless, which makes them a great option for apartments.

The gas boiler burner is designed for the combustion of natural gas. The gas first passes through the filter by a gradual electric valve, and the air required for their combustion is provided by a blower installed on the motor shaft.

If the combustion air pressure is lower than a certain limit or the gas pressure is higher or lower than the desired value, it is sensed by the built-in pressure sensors, and the relay command will turn the burner for the boiler off.

In gas boiler burners, the flow of the incoming air is controlled by the air damper installed in the burner boiler body, which can be either manual or automatic based on the capacity.

Gas Boiler Burner Components

The components of a gas boiler burner are as follows:

- Manual shut-off valve

- Gas filter (corresponding to the diameter of the boiler burner gas supply pipe)

- Burner body

- Gas solenoid valve

- spark trans

- Spark electrode

- flame wearer

- Control relay

- Gas and air pressure switch

- Fan and electric motor

- Air adjustment damper (manual or motorized)

- Flame spreader

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

.jpg)

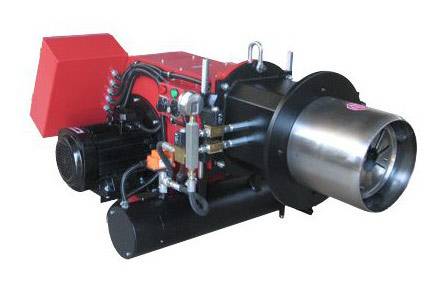

Liquid Fuel Boiler Burner

First, the liquid fuel is atomized by the pressure of the pump, which is selected according to the capacity of the boiler burner, so that its combustion can be done efficiently. The atomized fuel is then sprayed by a nozzle, mixed with air, and then ignited.

Remember that the igniter must be removed from the combustion chamber after it is on fire. It is necessary to atomize the liquid fuel before combustion because most fuels are not easily ignited in a liquid state due to their low octane number.

For example, if we put a lighted match into a combustion chamber containing diesel, the flame will quickly appear. Therefore, to burn such fuels, it is necessary to convert them from liquid to powder. Atomizing the fuel increases its surface contact with oxygen in the air, making it easier to combust.

The flow rate of 1 gallon of diesel fuel at a working pressure of 7 bar can be converted into more than 50 billion drops of oil per hour using a nozzle. The size of these drops varies from 0.0002 to 0.01 inches.

Through this process, the contact surface of the fluid increases about 3800 times. If the atomization is incomplete, the droplets’ size will be too large, and these particles will be incompletely ignited and come out of the flame in a semi-burnt form.

This problem sometimes occurs in the form of fire particles being thrown into the flame of some diesel burner for boilers. This only causes incomplete combustion. The result will be low efficiency, as well as the formation of deposits in the boiler's combustion chamber.

Mazut Boiler Burner

In Mazut boiler burners, the process of atomizing the fuel is done by a nozzle that creates these drops with a specific pattern. The atomized fuel must exit the nozzle within a certain angular range, and the distribution of fuel droplets must be even and normally in a conical pattern.

If you are using a Mazut boiler burner, it is necessary to install a preheater (fuel) in order to prevent the solidification of Mazut fuel in cold weather.

Diesel Burner for Boiler

In diesel boiler burners (not suitable for houses due to their size), the electric motor is also responsible for the rotation of the pump shaft, in addition to the function of moving the shaft of the aeration fan. In large boiler burners, an extra electromotor is installed to increase efficiency.

The aeration fan of the diesel burner for boilers is a centrifugal fan installed on the shaft of the electric motor with about 2900 rpm.

By starting the engine of diesel burners, the ventilation fan spins and moves air molecules between its blades. To control the amount of air in the fan, an air damper is placed on its suction opening. The adjustment of the incoming air in small burner boilers is controlled manually, and in large boiler burners by a servo motor.

The amount of air passing through the damper is proportional and increases or decreases with the amount of fuel.

Diesel Boiler Burner Components

The components of a diesel boiler burner are as follows:

- Burner body

- Electro-Motor

- blower (fan or propeller)

- Diesel pump

- Diesel filter

- Diesel solenoid valve

- Coupling

- Diesel Nozzle

- Trans ignition

- Spark electrodes

- Air damper

.jpg)

Note: In high-pressure boiler burners, a diesel burners' pump is installed in a rotary or gear form.

Liquid-Fuel Boiler Burners Main Groups

There are 4 main groups of liquid-fuel boiler burners, which are as follows:

- Pressure jet

- Rotary cup

- Air/stem-atomized

- Low-pressure air atomizing

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

Boiler Burner Liquid-Fuel Nozzle Performance

The fuel injection in pressure jet boiler burners is done by a small and delicate part called a nozzle. Nozzles come in various types in terms of fuel flow rate, fuel injection shape, and injection angle.

The diesel pump directs the pressured fuel into the nozzle. When the fuel exits the nozzle orifice, under the influence of centrifugal force, it moves away from the nozzle center and moves as a thin layer at high speed.

Regarding the spray pattern, nozzles are classified into three main types. Choosing a nozzle in terms of the fuel distribution angle and its pattern depends on the dimensions of the combustion chamber and the design of the boiler burner. The fuel injection angle in the nozzle is divided into six standard angles: 30, 45, 60, 70, 80, and 90.

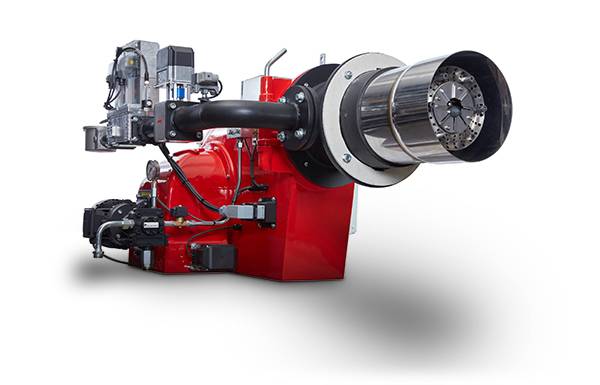

Dual-Fuel Boiler Burners

When the function of the boiler burner takes more than one type of fuel, it is called a multi-fuel burner for boiler.

Dual-fuel boiler burners usually work with gas and diesel, and if the device is also compatible with Mazut, it is called a triad-fuel boiler burner.

Therefore, the triad-fuel boiler burners, which must have a mazut preheater like the mazut-fuel boiler burners, can work with all three types of gas, diesel, and mazut.

Damatajhiz; Your Guide to Selecting and Purchasing HVAC and Mechanical Equipment (Since 2004)

The Impact of Burner Type on Boiler Room Efficiency

Heating efficiency in a boiler room is directly related to the burner type, capacity, adjustment, and overall performance quality. As the core combustion component, the burner is responsible for converting fossil fuel energy into thermal energy. Improper selection or mismatch with the boiler capacity can lead to increased fuel consumption and reduced boiler room efficiency.

Optimal burner performance has a direct effect on improving the combustion process, reducing energy consumption, and ensuring the reliable operation of mechanical systems. Selecting a suitable burner based on the fuel type and the thermal capacity of heating equipment, such as cast iron and steel boilers, enhances overall efficiency and improves heating system performance. Burners vary in operation depending on fuel type and combustion method, and each type has its own advantages and limitations.

- Gas burner: With precise flame adjustment and proper combustion, this type of burner helps reduce pollutant emissions. Easy maintenance and efficient fuel consumption are among its key advantages.

- Diesel burner: This type is suitable for areas without access to natural gas. It requires regular maintenance and adjustment, and improper management may result in increased fuel consumption.

- Dual-fuel burner: Capable of operating with both gas and diesel, it offers high flexibility in ensuring a stable fuel supply and enables energy optimization and continuity.

Regular maintenance and periodic servicing of burners play a crucial role in maintaining boiler room efficiency and preventing unexpected failures. The use of burners with complete combustion and smart control systems helps reduce fuel consumption and improve overall energy efficiency.

Comparison Table of All Types of Boiler Burners

If you want to be able to compare all types of boiler burners, in order to select the best option according to your needs, you can use the following table:

| Features / Burner Type | Gas-Fuel Burner | Liquid-Fuel Burner | Dual-Fuel Burner |

|---|---|---|---|

| Fuel Used | Natural gas, city gas | Diesel, Mazut, Kerosene | Combination: Gas + Diesel (or Gas + Mazut) |

| Main Types | With fan (blower) and fanless | Pressure jet Rotary cup Air/steam-atomized Low-pressure air atomizing |

Dual-fuel (Gas + Diesel) Tri-fuel (Gas + Diesel + Mazut) |

| Combustion Process | Direct combustion with air damper adjustment + gas solenoid valve | Fuel atomized by a nozzle, mixed with air, then ignited | Switches between fuels; requires preheater when burning Mazut |

| Main Components | Manual shut-off valve, gas filter, burner body, gas solenoid valve, spark transformer, spark electrode, control relay, gas/air pressure switch, fan & motor, air damper, flame spreader | Burner body, electric motor, blower fan, diesel pump, diesel filter, solenoid valve, coupling, diesel nozzle, ignition transformer, spark electrodes, air damper | Combination of gas and liquid burner components + fuel-switching system |

| Thermal Efficiency | High (especially with fan-assisted models) | Medium to high (depending on atomization quality & fuel type) | High, since it can use alternative fuels when needed |

| Pollution & Emissions | Low (with complete natural gas combustion) | Higher (carbon particles, sulfur in diesel/mazut) | Variable, depending on the fuel used |

| Operating Cost | Low (especially in regions with cheap natural gas) | Higher due to fuel cost and frequent maintenance | Flexible but usually more expensive than gas-only burners |

| Applications | Apartments, small boiler rooms, medium-size boilers | Industrial boilers, power plants, factories, areas without gas access | Large industries, power plants, hospitals, facilities needing fuel security |

| Advantages | Quiet (fanless type), low emissions, high efficiency, simple maintenance | Can operate without gas supply, suitable for high capacities, works with different liquid fuels | Flexibility, reliability, and higher fuel security |

| Disadvantages | Requires stable gas pressure, sensitive safety systems | Higher emissions, maintenance-intensive, soot and deposits in combustion chamber | Higher initial cost, more complex system and maintenance |

As you studied, the table includes advantages, disadvantages, applications, operating costs, thermal efficiency, main components, etc. of all main types of boiler burners.

Boiler Burner Fuel and Air Adjustment

The complete combustion of fuel is the result of the precise adjustment of the fuel and air ratio. The more accurate this ratio is, the higher the combustion efficiency and, as a result, less fuel is needed.

In small boiler burners, the adjustment of the air required for combustion is made by a manual damper. But in large burners for boilers, this adjustment is made with the help of an automatic damper.

The air damper must be reset every season by a professional operator. However, modern boiler burners are equipped with a smart PLC control system that automatically adjusts the ratio between fuel and air.

Performance of a Boiler Burner

Burners consist of a few parts, each with its crucial tasks, which are explained in the following:

- The Fan Burners: In fan burners, the start of operation is based on the temperature setting of the boiler’s thermostat and the burner’s relay command. Then, the burner ventilation fan is turned on for 30 to 60 seconds, allowing fresh air into the combustion chamber.

Next, the burner ignition transformer starts to create a spark. After that, the burner fuel solenoid valve (gas, diesel, or fuel oil) is opened. Then the fuel passes through the solenoid valve and enters the combustion chamber. Now, with the air and fuel being mixed, the ignition causes the flame to form. - The Photocell: After the flame formation, there is no need for ignition or spark. And with the command of the photocell or ion, the ignition transformer's function is stopped through the relay, and the burner continues to burn until the shutdown command is given.

- The Electromotor: The electromotor fan type of aeration depends on the capacity of the burner and the electricity type (single-phase or three-phase), although they usually rotate at 2900 rpm.

- The Body of the Burner: Usually, the body of most gas and diesel burners is made of cast aluminum, and the parts are typically installed on it.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

The Schema of Boiler Burners Mechanism

The liquid fuel is fully atomized by the pressure generated from the diesel or heavy-fuel-oil pump, which is selected according to the burner’s capacity. This atomization ensures proper combustion. The atomized liquid fuel is then mixed with air through one or more nozzles (depending on the required capacity).

The fully prepared fuel–air mixture is ignited by the spark produced from the ignition transformer. It should be noted that the combustion products, after transferring their heat, must be discharged from the combustion chamber.

According to the technical information and reasonable prices provided for all types of boiler burners in the specialized and reliable collection of DamaTajhiz (as an official member of the heating and air conditioning equipment sellers' union), we sincerely hope that you, while reading the complete technical specifications provided, choose DamaTajhiz for buying your required products.

Boiler Burner Thermal Capacity Estimation

Different calculations can determine the heat capacity of gas and diesel boiler burners used in engine houses.

One of the usual methods for calculating the heat capacity of boiler burners is to use the thermal power of the fuel. Thermal power refers to the amount of heat produced by the fuel per unit of time. To calculate the heat capacity of boiler burners, you can use the following formula:

Q Burne r=Q Boiler × SFQ Burner = Q Boiler × SF

Important Points:

- Q Burner: Indicates the thermal capacity of the boiler burner in kilocalories per hour.

- Q Boiler: The capacity of the engine room hot water boiler is in kilocalories per hour.

- SFSF: Reliability coefficient or depreciation coefficient, which is considered between 10% and 20% higher than the nominal heating capacity of the boiler or heater. Usually, a factor of 20% is appropriate.

After calculating the capacity of the boiler burner (Q Burner) using the above formula, you can choose a suitable model of the boiler burner from the DamaTajhiz HVAC.

Boiler Burner Fuel Consumption Estimation

The following formula is used to calculate the fuel consumption of the boiler burner:

m = Q Fuel / Q Burner

Important Points:

- m represents the flow rate of fuel consumption in liters per hour (Lit/hr).

- Q Burner displays the heat capacity of the boiler burner in kilocalories per hour (Kcal/hr).

- Q Fuel represents the heat capacity of the fuel (such as diesel or natural gas). For diesel, it is usually in the range of 9200 to 9700 kcal/liter, and for natural gas, it is about 8600 kcal/m3.

- Burner efficiency depends on several factors, including air density. Boiler burner efficiency is usually determined based on the manufacturer's catalog and decreases with increasing altitude. Normally, with every 300 meters of altitude increase, the combustion efficiency of all types of fuels (gas, diesel, fuel oil, gasoline, etc.) decreases by about 4%.

How to Choose the Right Burner for Boiler?

Manufacturers of boiler burners usually provide the thermal power of each boiler burner in tables that include the minimum and maximum thermal power of the boiler burners. Paying attention to these numbers is very important in choosing the right burner for boiler for specific needs.

The important parameters that are considered for choosing and calculating the right burner for boiler in boilers and heaters are:

- Type of Fuel: The type of fuel used (such as diesel or natural gas) plays an important role in choosing a boiler burner. The calorific value of fuel and its characteristics can have a great impact on fuel consumption and boiler burner capacity.

- Altitude: Altitude has a direct effect on combustion efficiency and choosing the right boiler burner. Higher altitude reduces air density and reduces oxygen in the air, which itself leads to a reduction in boiler burner combustion efficiency.

- Device Efficiency: The efficiency of the thermal device (boiler or furnace) is determined according to the height above sea level. This parameter indicates the efficiency of the device in converting fuel into heat. At high altitudes, combustion efficiency generally decreases due to the decrease in air density.

- Type of Combustion Chamber: Type of boiler (steel or cast iron boiler), dimensions of the combustion chamber, and other characteristics that have a direct impact on the choice of boiler burner.

- Boiler Capacity: The thermal capacity of the boiler or furnace, which represents the ability of the boiler to produce heat in kilocalories per hour (Kcal/hr). This parameter is considered one of the most important criteria in choosing a boiler burner.

- Confidence Interval: This coefficient is usually between 10% and 20% more than the heating capacity of the boiler or heater and is added to the burner for boiler capacity.

Also, in the selection and calculation of the boiler burner, the use of special software for facility engineering can help the accuracy and efficiency of the calculations.

Buying Burners for Boilers

In order to buy the most efficient boiler burner for your boiler, you must first determine the type of fuel, capacity, and then the diameter of the boiler burner flame tube, the brand, and then the model of the required burner for boiler.

On the website of Damatajhiz HVAC, the technical information of dozens of boiler burners from reputed brands, along with their OG guarantee, has been presented for you to enjoy the optimal and smart shopping.

Also note that in the specialized HVAC group of Damatajhiz, all the fuel boiler burners are only sold in bulk. Therefore, if you want to wholesale any of these products, feel free to contact us.

Note: When buying a boiler burner, you should consider the capacity of the burner for boiler to be about 20% more than the capacity of the corresponding boiler due to the incomplete fuel combustion efficiency in boiler burners and the heat loss.

Boiler Burner Price

The prices of boiler burners vary depending on their thermal capacity, pressure range, fuel type, and other factors. Briefly, there are burners for boilers from 140 USD up to 5000 USD in the world's markets. You can browse and examine all types of burners at the best prices only in DamaTajhiz HVAC. The price of burners varies according to the models and brands available; it should be noted that the prices presented in the DamaTajhiz HVAC are up-to-date, with a generous discount already included. Therefore, the best price for all types of burners is guaranteed for wholesale purchase.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. Please contact us by phone call or WhatsApp message through the phone number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.