Steel Hot Water Boiler

The steel fire-tube hot water boiler is one of the most critical components at the core of a building’s central heating system. Below, the technical specifications, operating pressure, selection criteria, and purchase price of steel hot water and high-temperature water boilers are presented.

Steel Hot Water Boiler Expert Selecting Guide and Price List

In general, steel hot water boilers are applied for supplying hot water for buildings by using the heat from the combustion of the burner and heat exchange between the absorption surfaces of thermal energy with the heat transfer fluid.

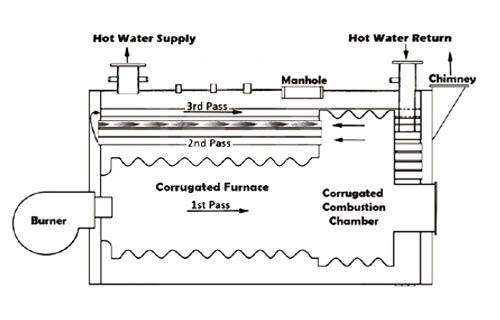

Regardless of capacity, dimensions, and working pressure, hot water boilers are also divided into "fire tube" and "water tube" types.

Note: Considering the importance of heat exchange levels in hot water boilers, some manufacturers insist on increasing these heat exchange rates according to standard implementation methods and plans. They also use the bottom surface of the boiler for water circulation and heat exchange. These boilers are called "wet back" boilers, and they have better heat exchange efficiency but a higher price than "dry back" boilers.

Review, Selection, and Pricing of HVAC Equipment

Types of Steel Hot Water Boilers

In general, steel hot water boilers are divided into the following types in terms of design and application, working temperature, capacity, and working pressure.

Types of steel hot water boilers are as follows:

- Firetube dry back flame steel hot water boiler

- Firetube 2-pass dry-back steel hot water boiler

- Firetube 3-pass dry-back steel hot water boiler

- Firetube 3-pass wet-back steel hot water boiler

- Firetube condensing steel hot water boiler

- Firetube Wetback 3-pass steel hot water boiler

- Firetube dry-back 3-pass steel hot water boiler

- Steel water tube boiler for power plant and industry

- Industrial hot oil steel boiler

Which Type of Hot Water Boiler Has the Best Efficiency and Longevity?

When choosing and ordering a hot water boiler for your project or industrial complex, be sure to consider the following factors:

- Compliance with the valid and recommended standards regarding the type of steel used in the body, furnace, and tubes.

- Follow all executive instructions in accordance with the construction plan of reputable and international brands in the field of hot water boiler construction.

- Not relying on advertisements regarding the quality of products and choosing the type, capacity, and working pressure of the required boiler.

For example, the best choice of hot water boiler for a capacity higher than 600,000 kilocalories per hour or 600 kilos of steam per hour, three-pass full-wetback boilers with main and secondary furnaces made entirely of Corrugated and refractory tubes and completely spiral, have the highest efficiency and longevity in fire tube boilers.

Advantages of Steel Hot Water Boilers

Steel hot water boilers are among the most popular choices for HVAC engineers. Some advantages of steel hot water boilers over cast-iron boilers and the other types are mentioned in the following:

- High thermal shock tolerance

- Higher efficiency than cast iron hot water boilers.

- Ability to produce steel boilers in very high capacities

- Ability to withstand high pressures (can be used in high-rise buildings)

Hot Water Boiler Steel Grade, Standard, and Construction Plan

As steel hot water/steam boilers are among the most important means and main pieces of equipment in the boiler room projects, the manufacturers of this product must produce them based on internationally accepted standards in the construction of steel hot water boilers in terms of design, body material (shell), furnace or combustion chamber, and networks must be made of special alloy steels for the construction of pressure and heat tanks in accordance with DIN 17MN4 or ASMEA516 / G70.

Moreover, the material of boiler tubes from seamless fire tubes according to DIN ST 35.8 with the possibility of suitable welding or expandability. In other words, even the use of high-quality alloy steel and the fire tubes mentioned above cannot alone guarantee the performance, efficiency, and useful life of the steel hot water boiler.

However, it is necessary to manufacture and produce hot water and steam boilers using approved plans and also according to defined methods and accepted international standards.

This point is so important that the construction of a steel hot water or steam boiler without the use of documented and internationally approved plans (even assuming the use of the best steel and production equipment), even by the most well-known boiler manufacturers is not considered to have a valid and justifiable standard.Another important point regarding the construction and production of a standard hot water boiler is how they connect the fire tube boiler to the tube plates at the front and back of the boiler.

This connection must be made by the expand (waltz) method, except for the resistant pipes inside the sub-burner, which must be done according to the standard by the expand welding method and using special devices approved by ISAB for welding.

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

Water Tube vs. Fire Tube Boilers

Choosing between a fire-tube and a water-tube boiler depends on your project type and budget. So, here are the three main differences between a water tube boiler and a fire tube boiler to help you decide according to your needs and budgets:

Functionality of Water Tube vs. Fire Tube Boilers

In fire-tube boilers, the flame and smoke from the burner pass through the pipes of the boiler, heating the water. However, in water tube boilers (such as power plant boilers), the heat of the burners occupies the main space of the boiler and heats the water. Likewise, it is notable that the water tube boilers come in very high capacity ranges.

Working Pressure of Fire Tube vs. Water Tube Boilers

The water tube boiler is the type of hot water boiler that is made to work at high pressures. These types of steel boilers (usually used in power plants) produce steam up to a temperature of 550°C and at a working pressure of more than 100 bar.

The working pressure in fire tube boilers, on the other hand, is at a maximum of 30 bar. Firetube boilers have long steel tubes through which the hot gases of the furnace pass, and the water that needs to be converted into steam or hot water circulates through them.

Water Tube vs. Fire Tube Boilers in Terms of Price

Fire tube boilers can be a better option when it comes to the cost of construction and maintenance. In other words, fire-tube boilers are a bit more cost-effective than water-tube boilers.

The Effect of Corrugated Furnaces & Pipes on Boilers Efficiency

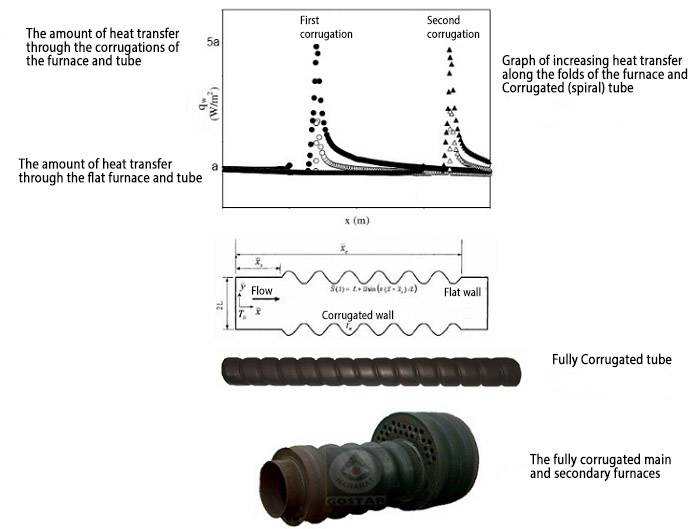

Nowadays, due to the importance of convection heat transfer in increasing the efficiency of boilers and water heaters, the use of techniques that can improve heat transfer has increased.

Based on complete studies on increasing heat from the heat transfer method, known as V.H.T.E. (Vortex Heat Transfer Enhancement), and as the name implies, the basis of work in these methods is based on the creation of a vortex.

One of the widely used methods of the V.H.T.E. is the use of curved or corrugated furnaces and tubes in hot water boilers. This works by producing more turbulence in the fluid flow that causes an increase in heat transfer, therefore, increasing the efficiency of the boiler.

Research has shown that the heat transfer at the curves in the furnace and corrugated pipes has a very complex pattern. But, in summary, the heat transfer in the corrugated furnaces and pipes is almost five times the heat transfer in the normal ones.

Also, fully corrugated furnaces and pipes greatly increase the efficiency of the hot water boiler due to the curves, and as a result, the increase of the radiation heat transfer and the total increase of displacement heat transfer in the V.H.T.E method.

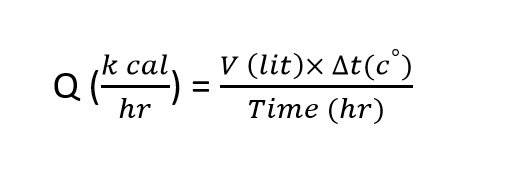

Hot Water Boiler Capacity Calculation

To meet the approximate heating requirement of swimming pools, hot tubs, etc., and add that to the capacity of the boiler, the following formula always works.

In this formula, the volume of the pool water is in 'liters,' and the temperature difference is in 'Celsius.

Usually, the temperature difference of the water entering the pools (according to the 10-12°C temperature of the water piping) is about 20 °C, and the temperature difference of the water entering the hot tubs is considered to be about 30 °C. These numbers should be included in the above formula as (ΔT).

Although the heating time of a swimming pool or hot tub does not follow any specific rule or standard and depends on many factors, such as the type of pool usage, on average, the water heating time in indoor pools is between 18 and 24 hours, in public pools between 48 and 72 hours, and in hot tubs between 4 and 8 hours.

Note: The amount of heating obtained from the above formula is suitable for indoor swimming pools and hot tubs. Moreover, for an outdoor pool, this number should be multiplied by 2.

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

The Challenge of Engineers and Facility Experts in Choosing Condensing Boilers

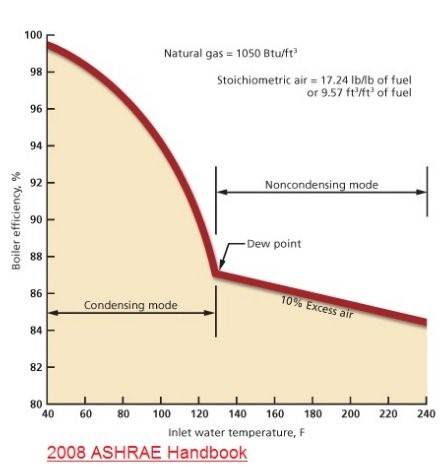

No doubt, condensing hot water boilers theoretically have high efficiency due to the possibility of absorbing latent heat in water vapor resulting from combustion.

However, to achieve this efficiency, we need to reduce the temperature of the water returned to the boiler to a temperature lower than the dew point temperature, as the main condition for the condensation function in the hot water boiler.

In fact, the condensing boiler works as condensation only in a certain range of the temperature of the heat carrier fluid. Unfortunately, in other cases, it works like a normal boiler in terms of efficiency.

Briefly, despite the claim of '92% to 94%' efficiency of condensing boilers, due to several technical and economic reasons that are sometimes and briefly mentioned below, the claim of this efficiency and economic efficiency faces serious challenges.

Low Water Return Temperature Challenge in Choosing Condensing Boilers

Basically, condensing hot water boilers face a challenge called low return water temperature; according to curve number 1, in condensing boilers, to achieve 96% efficiency, the return water temperature of the boiler should be 90 °F (about 50 °C).

With the temperature of the return water of 55 °C (about 130 °F (ca. 54 °C)), the efficiency of the condensing boiler reaches 87%, which will be equal to the maximum efficiency of three-pass full wetback fire tube boilers with the main and secondary burners of all CORRUGATE types and spiral fire tubes.

In England, more than 90% of condensing boilers have never operated in their condensing phase and are used in their non-condensing phase. Meanwhile, the important question is, "What is the justification for building the world's largest condensing boiler?"

The presented curves only show the maximum efficiency values, and the actual efficiency of condensing hot water boilers varies like other boilers in the range of A to G. At the same time. Currently, there is no standard to conduct tests to determine the efficiency of hot water boilers by legal authorities. It does not exist, and the claimed efficiency is without conducting the relevant tests.

Apart from all the problems of repair, maintenance, provision of spare parts, creating problems in the design of the spa temperature back below 40°C and the high price of the condensing boilers, in the best conditions, their nominal efficiency is at most 6% higher than the fire tube three-pass full wetback spa boilers with the main and secondary burners, will be entirely corrugated accordion and spiral fire tubes.

Which does not have an economic justification with scientific and economic analysis. According to the authoritative "Guardian magazine", even in a country like England, despite the very high price of fuel. It has not been able to justify its high price economically, and consumers have complained about the lack of cost reduction despite the high initial cost of these devices.

Operation Failure Possibilities

Considering the importance of the boiler burner as the heart of the central heating system of the buildings, and the need to consider the possibility of defects and failures in their operation (in the long term), as well as the opportunity of saving as much fuel as possible.

If the number of residential units in the building is 8 units or more, or the total surface area of the building's useful basement is more than 1000 square meters, according to the installation standards, it is recommended to install two steel hot water boilers, each capable of providing 60% of the required heating capacity of the entire building.

The Number of Required Boilers for a Building

In public buildings such as hospitals, hotels, etc., regardless of the type of boiler selected (cast iron or steel) for the central heating system, according to the recommendation of international engineering standards, 3 boilers are required.

Each of them must have enough power to supply 75% of the building's heating needs, so when one of them is damaged or malfunctions, one boiler alone can provide a major part of the heating needs.

Engine Room Standards

Considering the importance of the engine room or powerhouse as the provider of cooling and heating, it is recommended that the location of the engine room should be considered in such a way that, in addition to the possibility of easy transport, it has a large entrance door for the possibility of carrying various equipment.

Having the appropriate size and area to facilitate installation, inspection, and possible repairs, as well as having sufficient light and proper ventilation.

Other Important Factors for Boiler Capacity Calculation

There are other important factors to consider when calculating the capacity of a steel hot water boiler for your building's needs. The most critical of which are:

- The most important difference between a hot water boiler and a steam boiler is the high working pressure of hot water boilers.

- Before choosing any type of fire tube steel hot water boiler, check its dimensions and weight for entering and installing it in the engine room or powerhouse.

- When choosing a steel hot water boiler, in addition to the capacity and dimensions of the hot water boiler, also check the required working pressure of the boiler, and if needed, you can contact the experts of DamaTajhiz HVAC Group.

After choosing the most suitable hot water boiler and before transportation, the foundation should be leveled at the place of installation of the boiler and executed with suitable dimensions. So that after transportation, the boiler can be placed directly on the corresponding foundation in the powerhouse or engine room.

DamaTajhiz: The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

Steel Hot Water Boiler Installation Tips

Here are the 5 most important factors and tips you should consider when installing a hot water boiler:

- Considering that the installation of all the main equipment of the engine room, including the central heating boiler, is done on the pre-made concrete foundation with suitable dimensions according to the location plan, and exactly where the equipment is located. Therefore, before installing the main equipment of the powerhouse, install the required concrete foundation according to the defined dimensions and standards.

- In engine rooms where a steel or cast-iron hot water boiler is used, it is necessary to install a water softener and/or deposit filter.

- Installing a manometer thermometer on the housing to show the temperature of the hot water in the boiler, as well as the pressure of the heating system, is mandatory on every steel hot water boiler.

- Installation of a submerged thermostat (Augusta Smart Thermostat) with a temperature range of 30 °C to 90 °C (30 °F to 110 °F) is required to adjust the boiler temperature and the on-off command to the burner relay on every hot water boiler.

- Also, install at least one safety valve and at least one submersible thermostat (submerged Augusta) with a temperature range of 30 to 160 degrees Celsius or more (based on the operating temperature of the hot water or hot water boiler) to adjust the boiler temperature and the on-off command to the burner relay. Warm water or hot water is required for every pot.

How to Increase the Lifespan of a Hot Water Boiler?

Here are eleven recommendations to increase the longevity of a steel hot water boiler:

- Boiler design and construction based on approved construction plans, as well as the executive instructions and accepted methods provided by international standards.

- Using steel and standard refractory pipes, the sufficient heat level of the tubes, the number of passes of the hot water boiler, and the waltzing of the tubes instead of welding in the connection to the tubes and plates.

- Using water softeners suitable for the volume of water circulating in the heating system, as well as a descaler on the engine room pipes in sufficient numbers and sizes.

- Installation of handhole valves with suitable dimensions and in the required places for the possibility of periodic inspections and services, and even the possibility of replacing the damaged ones.

- The quality of auxiliary equipment of hot water boilers is of particular importance, so the type and quality of auxiliary equipment used in hot water boilers have a significant impact on the performance, safety, lifespan, and efficiency of these boilers. Furthermore, to compensate for the loss of combustion efficiency of the burners, it is necessary to choose the nominal capacity of the burner to be about 20% more than the boiler capacity.

- Choosing the right number and capacity of the boiler so that even on the coldest days of the year, the central heating boiler is not required to work continuously and without interruption. (For example, in sensitive public service buildings such as hospitals, hotels, government centers, and large residential complexes, it is necessary to have multiple boilers so that there is always a hot water boiler ready to work.)

- Choosing a burner with a calculated capacity suitable for the boiler (up to 20% more than the capacity of a steel hot water boiler).

- Adjustment of the burner flame (burning blue and direct longitudinal flow of the burner flame in the hot water boiler).

- Carrying out periodic inspections and services, especially in relation to how the burner ignites in the hot water boiler, the correct operation of the level controls, safety valves, thermostats, etc.

- If a diesel burner is in operation, the type and angle of fuel injection from the diesel burner nozzle are determined based on the diameter and length of the combustion chamber of the boiler, and according to the suggestion of the boiler manufacturer.

- Accurate calculation and implementation of the chimney in terms of diameter and according to the volume of combustion air.

Buying a Hot Water Boiler for an Engine Room

One of the most important points in the design and production of steel hot water boilers for an engine room (in addition to the compliance of all construction parts, parts, and equipment, control, access, testing, etc.) is the compliance and approval of the construction of each boiler with the executive plans and instructions for the construction of the boilers from internationally recognized and reputable brands.

To choose the most suitable hot water boiler, you must first determine the capacity, working pressure, and other required features of the boiler.

On the website of DamaTajhiz HVAC, technical information on dozens of models of steel hot water boilers from reputable brands, along with their main guarantee, has been presented for you to enjoy the good feeling of an optimal and smart purchase.

Steel Hot Water Boiler Price Range

Steel hot water boilers come in a diverse range of prices. The price of steel boilers directly depends on their capacity, production quality, following the latest standards, etc. However, the prices in the world market vary between 250 and 3000 USD.

DamaTajhiz, the specialized center of MEP and HVAC equipment, offers various types of cast-iron and steel hot water boilers with the highest quality and at the best competitive prices. You can find the latest models of steel boilers in the range of 250 to 2700 USD.

Dear Users

While thanking you for your trust in the technical opinions of the heating equipment sales experts, it should be noted that the choice of the desired product brand is based on the capacity, working pressure of the boiler, standard plate, history, brand strength, service, and product price, which is ultimately determined by the buyer.

But in the hot water boiler, most of the users and buyers choose and buy the best-selling brands such as Hararat Gostar, Packman, Garma Gostar, Azar Dama Gostar, and Azaran Sanat Emertat due to their quality, price, and after-sales service.

Because the specialized group of DamaTajhiz HVAC Group provides all kinds of hot water boilers in the Middle East region, if you need a hot water boiler for any of the countries in the region, you can place your purchase order with confidence, product guarantee, and reasonable price. Please leave it to our sales experts.

You can order any HVAC and MEP products, including different types of air conditioners, air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet With You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.