Fan Coil Unit (FCU)

Fan coil units are used in buildings equipped with cooling and heating systems and are available in various types, including floor-mounted, ceiling-mounted, ducted, cassette, and wall-mounted models. In the following, the most important technical considerations, selection guidelines, and the best purchasing prices for fan coil units are presented.

Technical Guide to Fan Coil Unit Selection and Pricing

A fan coil unit is the smallest component of an air conditioning system used to transfer chilled water from the chiller or hot water from the engine room to the ambient air.

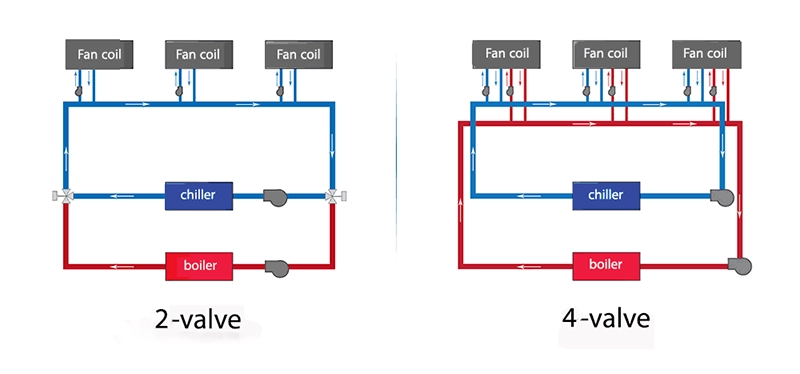

Fan coils usually have a two-pipe temperature exchanger coil for the inlet and outlet of chilled water from the chiller and hot water from the engine room or package and cannot cool and heat simultaneously (Except when four-way solenoid valves are installed and a four-pipe fan coil is used).

There are different fan coils in terms of use, installation location, and appearance, which we will describe in detail below.

Review, Selection, and Pricing of HVAC Equipment

Fan Coil Unit Advantages

The following are some of the most important advantages of the fan coil unit:

- The possibility of using fresh air in channel fan coils

- The failure of a fan coil does not affect other devices

- The possibility of controlling and adjusting the independent temperature of different spaces of the building

- Small installation space and no need for false ceiling and ducting in-ground and wall fan coils

- Variety in the design of fan coil units and the possibility of using different types of fan coil according to the needs of the project and building architecture

- Possibility of unlimited use of several fan coils with one or two chillers or a central engine room in large spaces

- Saving energy consumption by using heating through hot water coils and switching on and off intermittently (manually or automatically) the fan coil in empty spaces.

10 Important Points in Choosing Fan Coil Units

The parameters and important points that you should carefully consider when choosing and buying a fan coil are:

1. Fan Coil Unit Type

Fan coil units have different types such as floor-mounting, forward-blow, inclined, built-in ceiling (suction from below - suction from behind), four-way and two-way cassette, wall-mounted (such as split panel), ducted, etc. in different capacities.

They are selected and supplied by experts, engineers, and respected employers based on the need and type of order, also keep in mind that fan coil units have different capacities based on type.

The table below lists the typical ventilation, cooling, and heating capacity ranges of fan coils based on their type:

| Fan coil unit Type | Air capacity(CFM) | cooling capacity (kW) | heating capacity(kW) |

|---|---|---|---|

| wall-mounted | 600 - 200 | 5.5 - 1.5 | 10 - 2.8 |

| floor-mounted | 1200 - 150 | 11.9 - 1.7 | 19.7 - 3.9 |

| ceiling fan coil | 1200 - 200 | 12.5 - 1.7 | 19.5 - 3.5 |

| cassette fan coil units | 1200 - 300 | 13.5 - 2.6 | 22 - 4.5 |

| high-pressure cassette fan coil units | 2200 - 600 | 23.1 - 6.1 | 41 - 11.5 |

2. Fan Coil Unit Capacity

The most important factor in choosing a fan coil unit is the suitability of its cooling and heating capacity. When calculating, the capacity of the fan coil is determined based on the total cooling load (sensible and latent evaporation) of each space by the project facility engineers or after consulting with the experts of the air conditioning equipment department.

The estimated fan coil capacity required for each of the areas presented in the table below is approximate and based on the design temperature conditions inside and at the maximum fan speed.

At medium speed, the correction factor for the ventilation volume of the fan coils compared to the high speed is about 0.8, and the correction factor for the cooling and heating power in a temperate climate at medium speed is approximately 0.85. If necessary, you can contact the experts of DamaTajhiz HVAC.

For Hot and Dry Weather Conditions: The priority is to calculate the required cooling or refrigeration load in the winter season for each space and room of the project in weather conditions such as:

- Saudi Arabia: Yanbu, Jeddah, Mecca, Al Wajh, Al Hufuf, Unayzah, Buraydah

- Lebanon: Baslouqit, Bdebba, Baddouaa, Abu Saad, Aassoun, Deir Janine, Halba, Hakour, Haizouq

- Yemen: Ayn Milh, Tarim, Ard al Huwayl, Ard as Suqayr, Bayt al Mudir, Al Ma'shur

- Iraq: Amarah, Nasiriya, Kut, Kerbela, Semawa, Badrah, Rafaei

- United Arab Emirates - UAE: Dubai, Difan, Bida, Ghayl, Uwaynat, Ar Rafa'ah, Lazimah, Adh Dhayd, Layyah

- Qatar: Duha, Al Rayyan, Al Daayen, Al Wakrah

- Kuwait: Jahra, Sulaibiya, Al Wafra, Abdaly, Sabriyah

- Syria: Deir ez-Zor, Al Raqqah, Al Hasakah, Hama, Daraa, Aleppo, Homs, Idlib

- Turkey: Cizre, Urfa, Batman, Siirt, Izmir, Adana, Amasya, Istanbul

- Azerbaijan: Saatly, Sabirabad, Zerdab, Imishli, Beilagan

- Armenia: Armavil, Aragatsotn, Yerevan, Syunik, Tavush, Ararat, Kotayk, Lori

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

For Cold Weather Conditions: The priority of calculating the fan coil capacity is mainly based on calculating the required heating load for each space of the building in cold climate conditions such as:

- Saudi Arabia: Turaif, Sakaka, Abha, Rafha, Riyadh, Arar

- Lebanon: Baalbek-Hermel, Beqaa, Nabatieh, Akkar, Ain Dara, Beirut

- Yemen: Sa'dah, Dhamar, San'a, Al Mahwit, Al Jawf, Ma'rib, Shabwah

- Iraq: Sulaymaniyah, Dokuk, Nineveh, Kirkul, Saladin, Anbar, Muthanna, Babil,

- United Arab Emirates - UAE: Al Quwain, Al Khaimah, Fujairah, Ajman, Sharjah

- Qatar: Umm Salal, Al Shamal

- Kuwait: Farwaniya, Al Asimah, Hawalli, Ahmadi, Mubarak Al-Kabeer

- Syria: Damascus, As-Suwayda, Quneitra

- Turkey: Erzurum, Ardahan, Erzincan, Agri, Bayburt, Kars, Karabut, Kastamonu, Bingol, Hakkari, Van, Samsun, Bursa

- Azerbaijan: Kelbajar, Balaken, Gabala, Zagatala, Gahk, Shamkir, Sheki, Oghuz

- Armenia: Vayots Dzor, Shirak, Gegharkunik

The following table provides an approximate estimate of the use of ceiling, cassette, floor, cassette, and wall fan coil types for moderate climate conditions:

| Fan coil capacity | Maximum Infrastructure Used |

| 200CFM | to 12 mm |

| 300CFM | to 20 mm |

| 400CFM | to 28 mm |

| 600CFM | to 40 mm |

| 800CFM | to 56 mm |

| 1000CFM | to 70 mm |

| 1200CFM | to 80 mm |

| 1400CFM | to 95 mm |

| 1600CFM | to 110 mm |

| 1800CFM | to 120 mm |

| 2000CFM | to 140 mm |

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

3. Fan Coil Unit Dimensions

The dimensions of a fan coil unit are among the most important factors to consider when selecting and purchasing the system. The unit’s size and body dimensions must be fully compatible with the installation space to ensure both proper appearance and optimal performance.

This consideration becomes even more critical for concealed ceiling, cassette, and ducted models, since the main body of these units is installed inside a false ceiling or air duct. Even a small mismatch in size can lead to installation difficulties or require costly structural modifications.

Once again, it should be emphasized that the physical dimensions of fan coil units, especially concealed ceiling, cassette, and ducted types, are of particular importance.

Manufacturers typically offer a wide range of fan coil models with different capacities and dimensions, allowing buyers to select a unit that best fits their specific space. Therefore, it is strongly recommended to measure the exact dimensions of the installation area (length, width, and height)—especially in the ceiling or duct section—and compare them carefully with the technical specifications of the selected unit.

Doing so helps prevent issues such as incomplete ceiling closure, limited piping space, or difficult access for regular maintenance.

Finally, if the installation space is limited or the interior design requires precise fitting, always refer to the detailed dimensional drawings provided by the manufacturer. This ensures that the selected unit fits perfectly into the designated space and can be installed without complications.

4. Fan Coil Unit Coil Type

The coil is the passage of cold or hot fluid, consisting of several rows of copper tubes with aluminum fins. These are what you should look for when it comes to choosing a coil: the arrangement of the pipes, the number of rows, the type of protective coating on the fins (bluefin, gold fin), the type of pipes, the number of fins per unit and their waveform.

Three rows of 3/8 inch copper pipe are usually used in almost every coil type. Still, if a double-row coil with a diameter of ½ inch is used, it can reduce the heating efficiency and the pressure drop of the carrier fluid flow.

In some cases, to provide a simultaneous supply of cold and hot air day and night or to different spaces of luxury buildings, heating, and cooling fan coils are used, which have two separate coils; one coil for the flow of cold water from the chiller for cooling, and another coil for the flow of hot water from the boiler for heating, and this type of fan coil unit is called a "four-pipe fan coil unit".

The structure and piping of two-pipe and four-pipe fan coil units are shown separately in the figure below:

Note: There are several control valves on the way of the fan coil piping to change the direction or flow of water. Also, in two-pipe fan coils, due to the unavailability of hot and cold water at the same time, a sensor or changeover valve is placed in its piping path.

5. Fan Coil Unit Working Pressure

Considering that in buildings taller than 20 floors, the water pressure inside the coil will be more than 8 bar or about (PSI 120), when choosing a fan coil, consider the water pressure inside of the coil for high-rise towers.

6. Fan Coil Unit Motor Type

Electric motors of the fan coil units can vary from ones with 3-speed levels up to those with 8-speed levels, and they are usually made in two types: sealed or repairable. Mechanical parts and equipment of the fan coil units, such as bushes, shafts, ball bearings, etc., are made in different qualities, which can greatly impact the fan coil unit's sound level and lifespan.

The motor of the fan coil must be multi-speed and low noise with very reliable ball bearings, so that the operating noise of the electric motor and the ventilation fan is less than 35 dB.

7. Fan Coil Unit Fan Type

What the fan does is simple: it first directs the airflow over the coil's surface and then redirects it to the environment. The manufacturing companies of these fans have to consider major parameters, such as the sound level and the required air pressure to pass over the fan coil or channel when making these parts.

They make these parts out of either metal or compressed ABS plastic, each with advantages and disadvantages. Therefore, according to the device's application and the type of centrifugal ventilation, select the most effective type that suits your needs the best.

Another important topic to put to the examination is that these fans are usually produced in low-pressure at 30-pascal and high-pressure at 120-pascal types (for ducted fan coil units), and the power of the fan is generated by an electric motor, which we have talked about in the previous title.

The centrifugal fan should be made out of metal to maintain a dynamic balance during long operations, which, in this case, provides the required aeration volume of the fan coil more completely. However, if it is made of ABS, it will be less pricey.

Notes:

- Using the ABS fans is not recommended for areas with cold winters, and the water temperature of their central heating system is around 80 degrees Celsius in winter. In the long term, this temperature can change the shape of the fan in the vicinity of the hot water, which will end up with a louder sound for your device.

- In fact, the best option for airing fan coils is to use high-quality polyamide fans with carbon fibers, which, in addition to providing enough air with the lowest possible noise, are resistant to temperatures up to 120 degrees Celsius and do not change shape; Of course, on the other hand, the provision of polyamide fan is more expensive than both options of galvanized fan and plastic fan, and its provision may have higher time and cost for the manufacturer.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

8. Fan Coil Unit Appearance and Body

The body of the fan coil should be integrated so that it does not cause vibration and noise between different parts of the body over time. The beauty of the fan coil, especially floor-mounting fan coil units, which is practically one of the visible components of your building, should also be fully considered in the selection of the fan coil.

9. Fan Coil Unit Controller

The start time, change of speed, or shutting off the ventilation fan motor can be done manually and automatically. The best method for ceiling, wall, and ceiling fan coil units is a two-season, three-cycle automatic thermostat and an electric three-way valve.

All the floor fan coil units have a manual turn-on and off switch and a setting switch, but installing an automatic thermostat is one way to get the best out of their performance and optimize energy consumption. Turning on and off operation and changing the speed level of the blower motor is done by a room thermostat installed at a height of 140 cm from the ground and away from the airflow of the fan coil outlet and direct sunlight.

In a complementary way, by installing a gradual two-way solenoid valve or installing a three-way motorized valve, as well as by implementing the bypass route, it is possible to adjust the flow rate of cold or hot water by using the command received from the thermostat installed in each of the spaces. The inlet to the water supply pipe of the fan coil units also accurately controlled the supply of hot air and cold air by the fan coil units.

10. Fan Coil Unit Price

The price can be decisive when buying any product, yes, but when it comes to buying a product like a fan coil unit, which is a device that you can use for a long time, you do not want to miss some very important features just to spend a few less bucks.

Features such as the lifespan of the device, sound level, efficiency, capacity, appearance, warranty, and after-sales service are also very important. Therefore, it is safe to say that the fan coil price is not the most important factor considering its application.

Note: When buying a fan coil unit, it is important to pay close attention to this checklist: the type of fan coil you want to buy (regardless of the quality of the brand), the usage, architectural design of the building, parts, installation location, exact capacity, Dimension of the device, working pressure, construction quality of the device and its materials.

The Operation of Fan Coil Units

One of the most important questions before buying a fan coil is how it works.

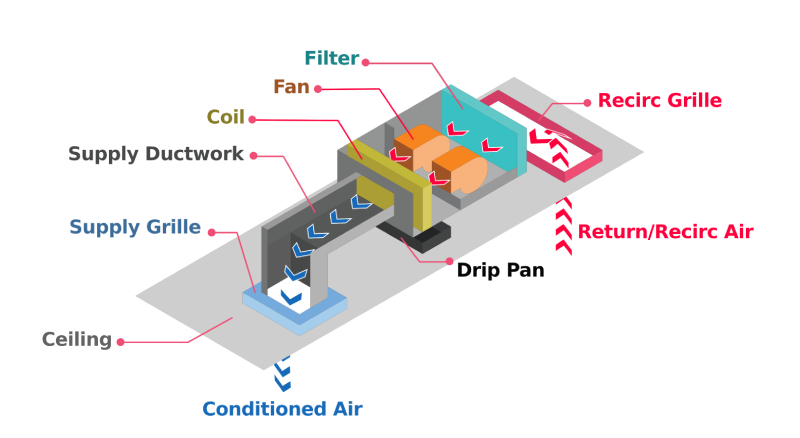

The fan coil works because when switched on, the airflow in the room is drawn into the unit by the blowing fans.

This air then passes through the unit's filter and coil (or heat exchanger) in cooling or heating mode, blowing a stream of cold or warm air back into the room.

This cycle is repeated continuously in the fan coil unit until the air in the room reaches the temperature desired by the user. An analog or digital selector switch or thermostat on the wall controls and regulates the room temperature.

To cool down the coils, cold water flows through the chiller in the copper pipes connected to the two units and is transferred to the coils; similarly, to heat the coils, hot water flows through the copper pipes through the central machine room or package and enters the coils.

The following figure shows the operation of the fan coil system and its internal components:

Fan Coil Unit Applications

Fan coil units are responsible for providing cool air in summer and warm air in winter, and this is done by passing air through a copper coil containing cold water from the chiller (in hot seasons) and hot water from the engine room or package (in cold seasons).

In general, fan coils are used in cases where we want the temperature of each area to be controlled separately by a thermostat installed in the same area.

One of the other advantages of fan coils is preventing the flow and transfer of air and possible air pollution between different rooms of a residential, office, accommodation, health, and hospital unit.

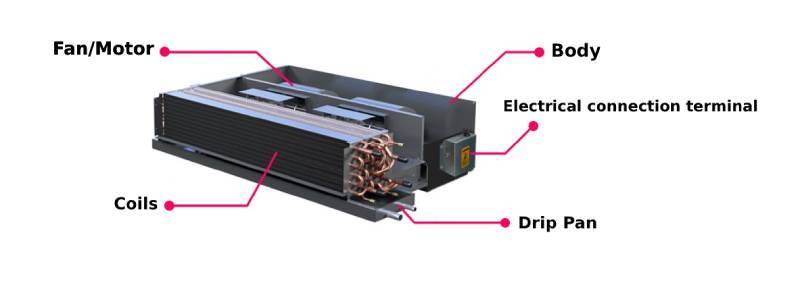

Fan Coil Unit Components

The internal parts and main components of the fan coil include the cabinet, coil, motor, fan, electrical box, and distillation tray, the use and operation of each of which are explained below:

- Fan: The fan installed in the fan coil moves and directs air over the coil's surface and into the desired environment. Different companies and manufacturers make different designs of the fans used in all types of fan coil units according to parameters such as sound level and providing the required air pressure to pass over the fan coil or duct. The material of the fans can be plastic, polyamide, or metal, which naturally vary in price to some extent.

- Coil: The coil or coils in the design of the fan coil system are a type of heat exchanger that is the place where cold or hot fluid passes. These coils are made up of several rows of copper tubes with aluminum fins and are known as (names of coils: two, three, and four rows) according to the amount and number of rows of copper tubes used. As three and four-row coils have more copper tubes and, therefore, more hot water capacity, their heating and cooling capacity is higher.

- Fan Motor: The motor or fan motor rotates and controls the unit's fan speed. Electric motors are available in 2 types (three turns or four turns) and are controlled by a button or digitally.

- Filter: The filter is placed in the air inlet of the fan coil to prevent dust and foreign objects, such as insects, from entering the unit.

- Drip Tray: The drip tray in the fan coils collects water droplets from distillation in the coils. It has a pipe to drain the water.

- Electric box: The fan coil's electric motor uses an electrical box for power and operation.

Different Types of Fan Coil Units

Five main fan coil units are available, including floor fan coil units, ceiling fan coil units, cassette fan coil units, wall-mounted fan coil units, and ducted fan coil units. We will explain each one shortly:

Ceiling Fan Coil Units

There are four types of ceiling fan coils, which are as follows:

1. Hidden Ceiling Fan Coil Units: Recessed ceiling fan coils (bottom suction - rear suction), available in cab and cab models, have ventilation capacities of 200 to 1,200 cubic feet per minute (CFM).

These devices are usually installed inside the false ceiling (at the entrance of each room), and only their valve can be seen from inside the room. One of the important advantages of these fan coils is low noise production and not occupying the environment space.

2. Visible Ceiling Fan Coil Units: these devices are produced in two types, low-pressure and high-pressure, and in terms of performance, they are similar to built-in ceiling fan coils (suction from below - suction from the back), With the difference that the body of these fan coils are fully exposed and occupy more space.

3. Cassette Fan Coil Units: Cassette fan coil units are a type of ceiling fan coil installed inside the false ceiling; however, controlling and adjusting their temperature or speed can be done by remote control in addition to the wall thermostat panel. Regarding ventilation, cassette fan coil units have one-way and four-way types.

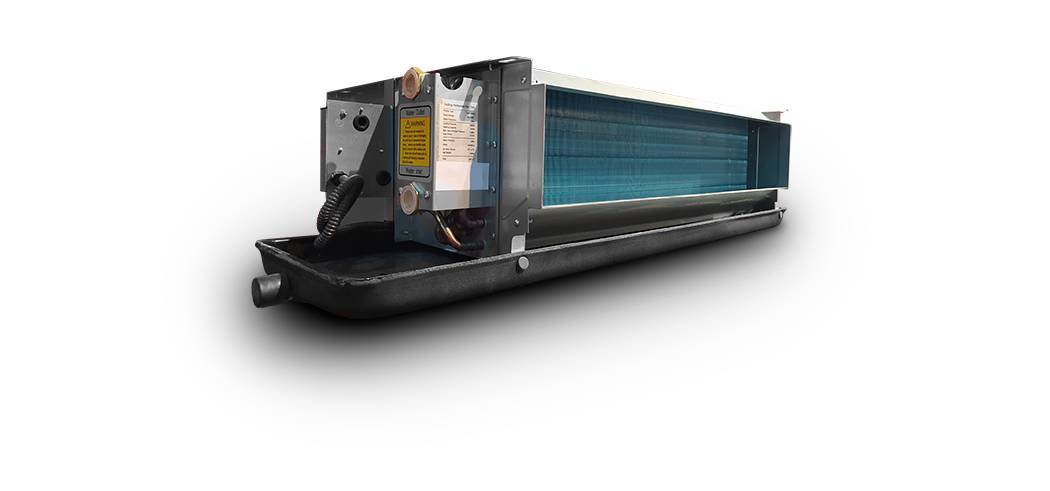

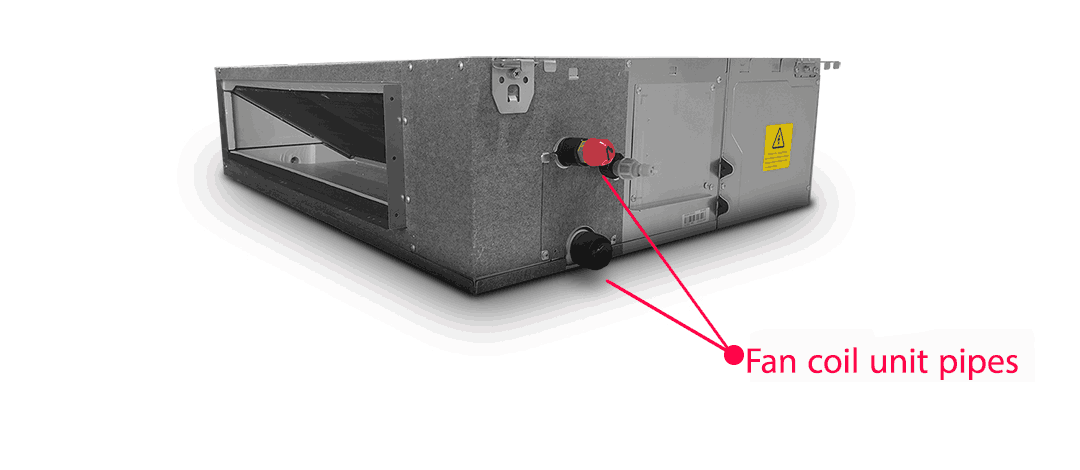

4. Ducted Fan Coil Units: Ducted fan coil units are usually produced in capacities of 600 to 2000 cubic feet per minute (CFM) and in two types: horizontal and vertical. It is necessary to check whether it is horizontal or vertical and the dimensions of the required ducted fan coil before inquiring about the price or placing an order.

Different Number of Pipes in Ceiling Fan Coil Units

One of the criteria for classifying the types of fan coils after the type of use and the place of installation (Ceiling, wall mount, and Floor Mount) is the type of piping, consider the number of water inlet (supply) and outlet (return) pipes to the fan coil, which is divided into two types:

1. Two-Pipe Ceiling Fan Foil:

Normally, fan coils have a heat exchanger (coil) in which cooling and heating operations are performed. This type of fan coil is called a two-pipe and its operation is that the water either cold water (from the chiller) or hot water (from the boiler) enters the coil through the inlet pipe (supply pipe) and after heat exchange with the air goes out through the outlet pipe (return pipe).

2. Four-Pipe Ceiling Fan Coil:

Based on the temperature conditions, architecture, design, utility, and special needs of the project some buildings require the simultaneous need for cold and hot air at the same time in different parts.

In this case, a four-pipe fan coil is recommended, as they are equipped with two separate heat exchange coils that can simultaneously provide the need for hot and cold air in different spaces at the same time. This device has two inlet pipes (supply pipes), and two outlet pipes (return pipes). Therefore, both hot and cold water flows in the coils of each fan coil at the same time so each unit can use cooling or heating separately.

Floor-Mounted Fan Coil Units

Built-in floor-mounted fan coil units are usually manufactured and supplied with 200 to 1200 cubic feet per minute (CFM) ventilation that emits cool or hot air as updrafts. As their name suggests, these fan coil units are installed on the floor.

Wall-Mounted Fan Coil Units (Split FCU)

Wall-mounted fan coil units, which have been available for some time, have attracted the attention of builders of construction projects and are installed on the wall.

This type of fan coil is similar in appearance to split air conditioners and for this reason, they are also called split fan coil units. Wall-mounted fan coils also do not take up much installation space and are relatively easier to install and maintain than other types of fan coil units.

Comparison and Evaluation Table of Different Fan Coil Types

The comparative table below reviews the common types of fan coil units used in HVAC systems in terms of application, airflow capacity, coverage area, energy consumption, air delivery performance, installation cost, unit price, noise level, maintenance requirements, and control features. Using this table, you can easily identify the differences and characteristics of each fan coil type and select the most suitable option for the intended space:

| Feature | Wall-Mounted Fan Coil | Floor-Standing Fan Coil | Ducted Fan Coil | Cassette Fan Coil | Concealed Ceiling Fan Coil |

|---|---|---|---|---|---|

| Application | Small residential and office spaces | Residential, office, and hotel buildings | Large residential units and office buildings | Office, commercial, and luxury spaces | Office, commercial, and false ceiling installations |

| Typical Capacity (CFM) | 200–800 | 200–1200 | 600–2000 | 600–1800 | 200–1000 |

| Coverage Area (m²) | 15–50 | 10–90 | 60–180 | 50–140 | 80-10 |

| Energy Consumption | Low | Medium | Medium to High | Medium | Low to Medium |

| Airflow Performance | Medium | Medium to High | High | High | Medium |

| Installation Cost | Low | Low | Medium | High | Medium |

| Unit Price | Medium | Medium | Higher | Higher | Low |

| Noise Level (dB) | 30–40 | 25–50 | 40–55 | 25–50 | 25–45 |

| Maintenance & Service | Easy (filter easily accessible) | Medium (moderate accessibility) | Difficult (limited access) | Medium (moderate accessibility) | Easy (accessible via false ceiling) |

| Control Features | Thermostat and remote control | Thermostat and remote control | Central control and thermostat | Remote control and thermostat | Thermostat and remote control |

Fan Coil Unit Features

The following are some of the features and benefits of fan coil units:

- High Efficiency and Sufficient Power: Fan coil units are designed with acceptable efficiency to provide sufficient power to transfer heat or cold. This helps increase the efficiency of the air conditioning system and reduce energy costs.

- Suitable Design for Limited Spaces: Fan coil units are typically used in limited spaces such as commercial, office, or residential spaces. Their compact designs allow installation in limited false ceiling spaces.

- Low-Noise Performance: Fan coil units are produced with special designs to reduce noise and create quiet operation of the ventilation fan. This feature is especially important in places that require the comfort of users.

- Temperature Control: Fan coil units can control temperature precisely. This feature is very important for creating suitable conditions in various environments such as control rooms, server and computer rooms, and laboratories.

- Support and After-Sales Service: Fan coil unit manufacturers generally provide good after-sales service. This includes periodic services, repairs, and replacement of defective parts, which helps extend the life and efficiency of fan coil units.

- Cost Efficiency: Due to the efficiency and effectiveness of fan coil units in energy consumption, significant savings are made in energy and operational costs for the consumer.

Fan Coil Testing and Verification

Considering the importance of fan coils as the final equipment for providing cooling and heating in projects, in cases where the number of fan coils required is high, usually, the consulting engineer or technical representative of the employer receives different samples of fan coils from different companies and selects them. They are examined and tested in the following factors:

- The appearance and dimensions of the device: due to the limitation of the installation space in the false ceiling of most projects, the dimensions of the fan coil and the possibility of its placement, especially in the false ceiling of each building space, are very important.

- The amount of output aeration volume: To measure the amount of actual aeration volume of a fan coil device and compare it with the number provided in the catalog of the supplier company, they use a laboratory kit called a CFM meter, which is usually accompanied by the representative of the selling company for performance testing. A fan coil bag is included.

- Measuring the amount of sound produced by the device: one of the important parameters in choosing a fan coil is the amount of sound produced by the device, which is used to measure the sound level of the device using a decibel meter.

- Sound and thermal insulation: the use of sound and thermal insulation with high quality, long life, and suitable thickness is also one of the parameters that play a significant role in the final selection of the fan coil. Failure to use proper insulation increases the sound of the device and wastes energy in it.

- The Quality of Materials: use of high-quality galvanized sheet with suitable thickness, use of high-quality electric motor, material of fan and fan blower, quality of construction and galvanized material of drain tray, etc., are also very important things that buyers should consider. Pay attention to them when choosing a device.

Buying a Fan Coil Unit

Out of all the mentioned aspects, the first step to choosing a fan coil unit should be to pay attention to the capacity, type of device, and dimensions of the installation location.

Because fan coil units are produced and supplied in different types with different ventilation capacities, you should consider the size of your environment before buying a fan coil unit. This is how you choose the right device with the right price. After those three aspects, things like the type of ventilation fan, coil specifications, working pressure, and fan coil brand should be considered.

Another important criterion when selecting a suitable fan coil unit is evaluating the noise level during operation and its overall efficiency. In residential, office, hotel, and healthcare environments, fan noise can have a direct impact on occupant comfort; therefore, fan coil units equipped with properly balanced fans, low-noise electric motors, and well-designed acoustic structures are highly recommended.

On the other hand, the operational efficiency of a fan coil unit depends on factors such as the type of fan motor, the number of adjustable speed levels, the number of coil rows, and the control method used. Choosing a unit with optimized energy consumption not only reduces operating costs but also contributes to extended equipment lifespan and stable, reliable performance of the HVAC system.

Here at the DamaTajhiz HVAC store, technical information of dozens of models of fan coil units from reliable brands with original warranties has been presented for you to enjoy the good feeling of optimal and smart shopping.

Advantages of Buying Fan Coil Units from Damatajhiz

Damatajhiz is recognized as the first specialized reference for the review, selection, and purchase of HVAC and mechanical systems in the country since 2004. The company offers a wide and diverse range of fan coil units from reputable brands at competitive prices.

Damatajhiz has consistently focused on providing professional technical explanations and comprehensive buying guides, enabling customers to make informed, reliable, and cost-effective purchasing decisions. Key advantages of buying fan coil units from Damatajhiz include:

- Fast worldwide delivery of fan coil units

- Availability of installment payment options for purchasing fan coil units

- Competitive pricing along with special discounts and promotions

- Easy and secure online purchasing of fan coil units

- Professional technical consultation by experts for selecting and purchasing various types of fan coil units

- Detailed technical information and guidance on capacity selection, fan coil types, technical specifications, leading brands, pricing, and fan coil buying guides

- A wide variety of fan coil models and capacities from top-selling Iranian and international brands, backed by official manufacturer warranties

Fan Coil Unit Price

The price can be decisive when buying any product, yes, but when it comes to buying a product like a fan coil unit, which is a device that you can use for a long time, you do not want to miss some very important features just to spend a few less bucks.

Features such as the lifespan of the device, sound level, efficiency, capacity, appearance, warranty, and after-sales service are also very important. Therefore, it is safe to say that the fan coil price is not the most important factor considering its application.

Price List of Best-Selling Fan Coil Brands

Dear project owners, in this section you can view the updated price list of fan coil units as of Dey 1404. This table includes the purchase prices of fan coils from well-known and best-selling Iranian and international brands such as Saravel, Tahvieh, Saran, Midea, Green, Damatajhiz, Sarmaafarin, and Hisense. The provided information covers the fan coil type, capacity, country of manufacture, and unit price.

Please note that these brands are ranked among the top fan coil and HVAC equipment manufacturers in terms of build quality, energy efficiency, and technical features. It is also recommended that before purchasing a fan coil unit, in order to obtain accurate pricing, review technical specifications, and receive professional consultation, you contact the specialists of the Damatajhiz technical group, in addition to reviewing the detailed information related to each brand.

| Brand | Country of Origin | Type | Capacity (CFM) | Approximate Price (USD) |

|---|---|---|---|---|

| Saravel Fan Coil | Iran | Ceiling-mounted, Floor-standing | 200 to 1200 | 190-530 |

| Tahvieh Fan Coil | Iran | Concealed ceiling, Cassette, Ducted, Floor-standing, Wall-mounted | 200 to 2000 | 180-700 |

| Saran Fan Coil | Iran | Ceiling-mounted, Cassette, Ducted, Floor-standing, Wall-mounted | 200 to 2000 | 190-650 |

| Midea Fan Coil | China | Concealed ceiling, Cassette, Ducted, Floor-standing, Wall-mounted | 150 to 2200 | 400-1400 |

| Green Fan Coil | China | Concealed ceiling, Cassette, Ducted, Ceiling-Floor | 300 to 2000 | 310-1300 |

| Damatajhiz Fan Coil | Iran | Concealed ceiling, Cassette, Ducted, Floor-standing, Wall-mounted | 200 to 2000 | 150-510 |

| Sarmaafarin Fan Coil | Iran | Concealed ceiling, Cassette, Floor-standing | 200 to 1200 | 160-650 |

| Goldiran GL Fan Coil | Iran | Concealed ceiling, Cassette, Ducted, Floor-standing, Wall-mounted | 300 to 2200 | 350-1200 |

Factors Affecting the Price of Fan Coil Units

The most important factors affecting the price of cooling and heating fan coil units are explained below:

1. Type of Fan Coil Unit

One of the main factors determining the price of a fan coil unit is its type. Each type of fan coil unit—including ceiling-mounted, floor-standing, ducted, cassette, and wall-mounted models—has a different price range due to differences in structure, installation method, and operating performance:

- Generally, concealed ceiling fan coil units are more affordably priced compared to other models. This is due to the absence of an external cabinet, compact dimensions, and the ability to be installed within false ceilings, making them an economical option for residential and office spaces.

- In contrast, cassette fan coil units usually come at a higher price. Their visually appealing design that blends well with interior décor, uniform air distribution in four or one direction, and the use of high-quality panels contribute to their higher cost compared to ceiling-mounted models.

- Ducted fan coil units are positioned in a higher price category due to their more powerful motors and fans, compatibility with ductwork systems, ability to serve multiple spaces simultaneously, and the need for more robust technical equipment.

- On the other hand, floor-standing fan coil units vary in price depending on their design type (up-blow or front-blow) and the quality of the cabinet construction. Their prices are usually close to, or slightly higher than, wall-mounted fan coil units.

- Wall-mounted fan coil units are also popular among project owners due to easy installation, minimal space requirements, and their visual similarity to split air conditioners. Their prices are typically higher than simple ceiling-mounted models and lower than cassette and ducted fan coil units.

2. Airflow Capacity of the Fan Coil Unit

The airflow capacity of a fan coil unit (CFM) has a direct impact on its price. As the airflow capacity increases, the unit dimensions become larger and more powerful motors, fans, and coils are required; consequently, the price of the fan coil unit naturally increases.

3. Fan Coil Unit Brand

The manufacturer’s brand is another important factor in determining the price of various residential and industrial fan coil units. Reputable brands typically use higher-quality components, more refined engineering designs, and more precise manufacturing equipment, all of which affect the final product price. In addition, imported fan coil units generally have higher prices than locally manufactured ones due to import costs and the continual rise in foreign exchange rates.

4. Technical Specifications and Component Quality

Technical specifications such as motor type, coil material, number of coil rows, fan type, energy efficiency level, and noise level are key factors influencing the price of a fan coil unit. The use of high-quality copper coils, energy-efficient motors, and optimized airflow design increases the unit price, but in return provides more stable performance and lower maintenance costs.

5. Additional Features of Residential and Industrial Fan Coil Units

The presence of additional features such as wall-mounted or digital thermostats, fan speed control, washable filters, solenoid valves, or the ability to connect to smart building management systems can increase the price of a fan coil unit. Although these features raise the initial cost, they often lead to improved performance, better system operation, and more effective energy consumption control in many projects.

Fan Coil Unit Installation, Operation, and Maintenance Tips

There are a few factors that must be taken into account when buying a fan coil unit, which are as follows:

- To calculate the cold water flow required for the fan coil units, the cooling capacity based on BTU/h of each building's spaces should be divided by 5000. (or dividing kilocalories per hour by 1250), this is how the diameter of the hot and cold water return pipes to the 200 cfm fan coil units is ½ inch. For 300 and 400 CFM fan coil units, ¾ inch and the fan, 600, 800, and 1000 cfm coils are 1 inch in size, and for 1200 fan coil units and channels up to 1800, ¼ 1 inch is considered.

- It is necessary to install a flow switch in the path of the outlet water of the evaporator towards the cold water coil of the air conditioning equipment to stop the chiller when the circulator pumps of the cooling circuit are turned off.

- Due to the greater heating ability of fan coil units than radiators of the same size, in old buildings, it is possible to install a fan coil instead of a radiator (only for heating) if the relevant pipes are from the floor of the unit (not from the back wall device) have been removed.

- Due to the importance of ventilation fan balance in the performance of fan coil units and its direct relationship with the lifespan of motor bearings as well as the noise level of the device, to maintain the dynamic balance of the ventilation fan of the device, compared to the completely horizontal and aligned installation of all types of fan coil units Pay utmost attention to your installation location.

- Due to the important issue of service and maintenance in air conditioning equipment, including fan coil units, installing the shut-off valve for the inlet and outlet water flow from the fan coil units and the relevant tube nut is necessary.

- To collect the water from the distillation of air humidity on the coils in summer, installing an ½ inch drain pipe from the tray under the coil to where these waters are drained is necessary.

Dear Users,

Reading the stated information above to obtain additional information to purchase the types of ceiling, floor, wall-mounted, and ducted fan coil units. You can also contact the experts of the AC equipment by dialing one of the extension numbers 117-119-120-126-317 to get advice or just to ask your questions.

While thanking you for the trust you put in the technical opinions of heating equipment sales experts of DamaTajhiz, it should be noted that the choice of the desired product brand based on history, brand strength, service, and product price is ultimately determined by the buyer. But in the field of fan coil units, most of the users and buyers choose and buy best-selling brands such as ventilation, Saran, DamaTajhiz, Saravel, and G Plus due to their quality, price, and after-sales service.

Also, considering that the DamaTajhiz HVAC is a member of the main group specializing in heating equipment, is the first and most viewed authority for selling air conditioning equipment, and is an official member of the heating and air conditioning equipment sellers' union. Therefore, it is safe to say that we provide all kinds of fan coil units in the Middle East region. Therefore, if you are from the same country in the region and you need a fan coil unit, please place your order with our sales experts team. Product warranty and a reasonable price are included.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.