Ducted AC Unit

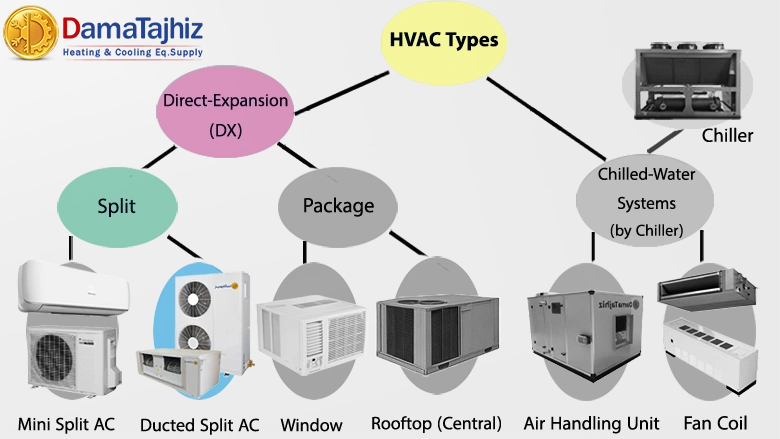

Ducted Split AC, also called Central Split AC, is an independent HVAC system designed to provide both cooling and heating for residential and office units. Below, you will find the technical specifications, capacity estimation, selection guide, and the purchase price list of ducted split systems.

Expert Guide to Selecting and Pricing Ducted Split AC

What is a ducted split system? You might think air conditioning systems are only for cooling, but a Ducted Split (Ducted Air Conditioner) offers both cooling and heating at the same time, delivering comfort and energy efficiency to homes and workplaces while ensuring uniform temperature distribution throughout the space.

The ducted split system, internationally known as Ducted Air Conditioner or Ducted Split System, is a term widely used by HVAC specialists to describe channel-type split air conditioners.

Ducted split systems are among the most common heating and cooling solutions for residential apartments and office buildings. They provide cool, comfortable air during summer and warm air in winter through a central heating source such as a boiler or package unit. Air is distributed via ducts installed above the false ceiling, maintaining a pleasant indoor climate all year round.

To obtain the exact and up-to-date price of a ducted split AC, the appropriate model must first be selected based on the building’s required capacity. You can receive free professional consultation from DamaTajhiz experts to accurately determine the required capacity.

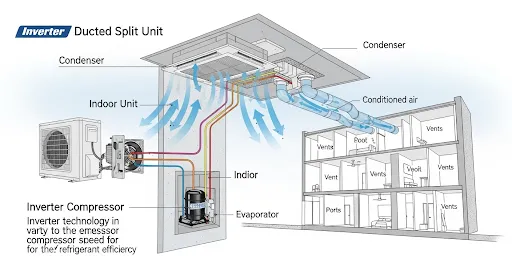

According to the technical data provided by DamaTajhiz, ducted split systems consist of two main components: an indoor unit (air handling unit) and an outdoor unit (condenser). These two units are connected through two insulated copper pipes for refrigerant circulation.

Indoor Unit (Air Handling Unit)

During summer, air is cooled inside the indoor unit and then distributed through installed ducts (within the false ceiling) to rooms or living areas of each apartment.

Outdoor Unit (Condenser)

The condensing unit is connected to the indoor ducted split unit via insulated copper piping and performs the required heat exchange for cooling using the compressor. Depending on site conditions, the outdoor unit can be installed on a balcony or rooftop.

Note: Due to the need for false ceilings and ductwork, the decision to install a ducted split system for residential or office units must be made during the building design and construction phase. (Air distribution through old evaporative cooler ducts is not possible.)

Review, Selection, and Pricing of HVAC Equipment

7 Key Factors to Consider When Buying a Ducted Split AC

Reviewing the following seven key factors will help you choose a system that meets your technical and budget requirements while ensuring comfort in your living or working environment.

- Dimensions and net floor area of the unit (residential or office)

- Required cooling capacity estimation based on usable floor area

- Location, dimensions, and height of the indoor unit (for installation above false ceiling)

- Brand, additional features, and advantages of the selected system

- Feasibility of duct installation from the indoor unit to all rooms

- Electrical current requirements and power supply type (single-phase or three-phase)

- Inverter ducted split systems with lower power consumption and higher efficiency

Latest and Most Economical Ducted Split Price List – 2026

In this section, the Ducted Split AC Price List – February 2026 is presented in a comprehensive table, allowing you to select the most suitable brand, type, and capacity for your space. The table clearly shows the wide range of capacities and prices available in ceiling-mounted ducted split systems.

Please note that some models have fixed prices, while others require updated price inquiries prior to purchase.

| Brand | Type | Capacity (Btu/hr) | Price (USD) |

|---|---|---|---|

| Midea Ducted Split | Concealed Ceiling | 24000-55000 | From 1,710 to 4,050 |

| Hisense Ducted Split | Ceiling Mounted | 18000-60000 | From 1,890 to 3,090 |

| Böyman Ducted Split | Ceiling / Concealed Ceiling | 18000-60000 | From 1,390 to 2,560 |

| GPlus Ducted Split | Ceiling / Concealed Ceiling | 24000-60000 | From 1,330 to 3,220 |

| Iran Radiator Ducted Split | Ceiling / Concealed Ceiling | 24000-36000 | Price on Inquiry |

| LG Ducted Split | Ceiling / Concealed Ceiling | 24000-54000 | From 2,025 to 4,520 |

| Green Ducted Split | Ceiling / Concealed Ceiling | 18000-60000 | Price on Inquiry |

| Trust Ducted Split | Ceiling / Concealed Ceiling | 18000-55000 | Price on Inquiry |

Estimating the Required Ducted Split Capacity

To estimate or determine the required duct split capacity for each residential or office unit you should consider about 1 ton of refrigeration for every 20-30 square meters (400 BTU/hr per square meter) of the total area of the apartment on the middle floors of the building, which are not exposed to sunlight on the ceiling in the summer and the cold of the roof surface in the winter for weather conditions such as:

- Saudi Arabia: Turaif, Sakaka, Abha, Rafha, Riyadh, Arar

- Lebanon: Baalbek-Hermel, Beqaa, Nabatieh, Akkar, Ain Dara, Beirut

- Yemen: Sa'dah, Dhamar, San'a, Al Mahwit, Al Jawf, Ma'rib, Shabwah

- Iraq: Sulaymaniyah, Dokuk, Nineveh, Kirkul, Saladin, Anbar, Muthanna, Babil,

- United Arab Emirates - UAE: Al Quwain, Al Khaimah, Fujairah, Ajman, Sharjah

- Qatar: Umm Salal, Al Shamal

- Kuwait: Farwaniya, Al Asimah, Hawalli, Ahmadi, Mubarak Al-Kabeer

- Syria: Damascus, As-Suwayda, Quneitra

- Turkey: Erzurum, Ardahan, Erzincan, Agri, Bayburt, Kars, Karabut, Kastamonu, Bingol, Hakkari, Van, Samsun, Bursa

- Azerbaijan: Kelbajar, Balaken, Gabala, Zagatala, Gahk, Shamkir, Sheki, Oghuz

- Armenia: Vayots Dzor, Shirak, Gegharkunik

To determine the appropriate capacity of a ducted split system for each residential or office unit, please consider the following important calculation factors:

- For an initial estimation of cooling capacity for concealed ceiling ducted split systems in apartments located in moderate climate cities such as Tehran, Mashhad, Karaj, Isfahan, Erbil, Kabul, Sulaymaniyah, and Aleppo, it is generally assumed that one ton of refrigeration is required for every 25 to 30 square meters of floor area. On average, each square meter of usable space requires approximately 400 Btu/hr of cooling capacity. If the total area of an apartment exceeds 120 to 130 square meters, it is recommended to use two ducted split units per apartment (one for the living area and one for the bedrooms). Please note that 12,000 Btu/hr is equivalent to one ton of refrigeration.

- For apartments with an area of up to 150 square meters, single-phase inverter ducted split systems (from certain brands) can be used with a 32-amp power supply, without the need to apply for three-phase electricity.

- Even for apartments with areas up to 200 square meters, some brands allow the use of single-phase inverter ducted split systems with a 50-amp electrical current.

- According to information provided by our experts, for residential units larger than 200 square meters, builders in Iran are required to obtain three-phase electricity based on regulations issued by Tavanir (Iran Power Generation, Transmission and Distribution Company).

- One of the key factors when selecting a ducted split system is its airflow rate. Typically, an airflow of 400 CFM per ton of refrigeration is considered appropriate. Naturally, lower airflow results in reduced noise levels, while higher airflow increases air noise.

- For convenience, you may refer to the approximate estimation table below to determine the required ducted split capacity based on the stated conditions and calculation principles.

🔔 Attention:

The following capacity estimation table is approximate and is intended only for residential apartments located in climatic conditions similar to cities such as Tehran, Rasht, Babol, Sari, Karaj, Mashhad, Isfahan, Kermanshah, Shiraz, Beirut, Erbil, Mosul, Aleppo, Hama, Mazar-e-Sharif, Kabul, Latakia, Kirkuk, and others. The calculations are based on a ceiling height of 2.8 meters, no occupant congestion, no additional latent heat load, no use of high-consumption electrical appliances, and no extensive glass façades, especially on the western side of the unit.

| Ducted Split Capacity (BTU) | Middle & Ground Floor Units (m²) | Top Floor Units (Below Roof) (m²) |

|---|---|---|

| Ducted Split 18000 | Up to 45 | Up to 35 |

| Ducted Split 24000 | Up to 60 | Up to 45 |

| Ducted Split 30000 | Up to 80 | Up to 60 |

| Ducted Split 36000 | Up to 100 | Up to 80 |

| Ducted Split 48000 | Up to 130 | Up to 100 |

| Ducted Split 60000 | Up to 150 | Up to 130 |

7. Before making the final selection of any concealed ceiling or ducted split model, be sure to check whether the unit requires single-phase or three-phase power and compare its rated current (A) with the capacity of the building’s electrical meter.

🌟 Note:

For hot and dry cities such as Zahedan, Zabol, Yazd, Kerman, Baghdad, Najaf, Karbala, and Madinah, or for hot and humid (tropical) regions such as Ahvaz, Abadan, Bandar Abbas, Kish, Chabahar, Doha, Bushehr, Bandar Mahshahr, Basra, Dubai, Abu Dhabi, Muscat, Sana’a, and Jeddah, selecting a ducted split system may require special consideration. In such cases, based on HVAC engineers’ calculations, in addition to choosing a unit equipped with a tropical (T3) compressor and condenser and evaporator coils with Gold Fin or Blue Fin coating, it is recommended to select a cooling capacity approximately 20% to 30% higher than the values shown in the table above.

You should also consider about 20 to 30% more cooling capacity than the table for weather conditions such as:

- Saudi Arabia: Yanbu, Jeddah, Mecca, Al Wajh, Al Hufuf, Unayzah, Buraydah

- Lebanon: Baslouqit, Bdebba, Baddouaa, Abu Saad, Aassoun, Deir Janine, Halba, Hakour, Haizouq

- Yemen: Ayn Milh, Tarim, Ard al Huwayl, Ard as Suqayr, Bayt al Mudir, Al Ma'shur

- Iraq: Amarah, Nasiriya, Kut, Kerbela, Semawa, Badrah, Rafaei

- United Arab Emirates - UAE: Dubai, Difan, Bida, Ghayl, Uwaynat, Ar Rafa'ah, Lazimah, Adh Dhayd, Layyah

- Qatar: Duha, Al Rayyan, Al Daayen, Al Wakrah

- Kuwait: Jahra, Sulaibiya, Al Wafra, Abdaly, Sabriyah

- Syria: Deir ez-Zor, Al Raqqah, Al Hasakah, Hama, Daraa, Aleppo, Homs, Idlib

- Turkey: Cizre, Urfa, Batman, Siirt, Izmir, Adana, Amasya, Istanbul

- Azerbaijan: Saatly, Sabirabad, Zerdab, Imishli, Beilagan

- Armenia: Armavil, Aragatsotn, Yerevan, Syunik, Tavush, Ararat, Kotayk, Lori

DamaTajhiz; Thousands of Products for Thousands of Projects (Since 2004)

How the Ducted Split System Works (Cooling & Heating)

Since ducted split systems, like conventional air conditioners, consist of an indoor unit and an outdoor unit, their cooling operation is very similar to split air conditioners and is based on the vapor compression refrigeration cycle.

In this process, the refrigerant gas is compressed inside the compressor at high pressure and temperature, then directed to the condenser. As the refrigerant circulates through the condenser and the fan operates, heat is discharged to the outdoor environment, and the refrigerant exits the condenser in liquid form.

The liquid refrigerant then passes through the expansion valve, where its pressure and temperature drop significantly before entering the evaporator coil. By absorbing heat, it cools a large volume of air, which is then distributed through ductwork to different areas of the unit. However, the heating operation of ducted split systems differs from standard air conditioners and is carried out using alternative methods, as explained below.

Heating Operation of Ducted Split Systems

In heating mode, a ducted split system operates differently from cooling mode. During winter, instead of using the compressor and refrigeration cycle, a hot water coil installed in the indoor unit is utilized. Hot water produced by a boiler or individual heating package flows through this coil, and as the indoor fan circulates air over the heated surface, warm air is supplied to the space. In this mode, the outdoor unit remains mostly inactive, resulting in significantly lower electrical consumption and reduced operating costs. This is a key advantage of concealed ceiling ducted systems compared to dual-purpose air conditioners, which consume high electricity and place heavy load on the compressor during heating.

Despite this advantage, the heating performance of ducted split systems has certain limitations. The hot water coil often cannot provide perfectly uniform heating throughout the entire building, which may cause dissatisfaction among some users. Therefore, a ducted split system alone may not fully meet heating requirements, and it is recommended to use supplementary systems such as radiators or underfloor heating for optimal comfort.

Setting a Ducted Split System for Winter

To operate a ducted split system in heating mode during winter, three main methods are available: hot water coil, electric heater coil, and heat pump, as described below:

a) Hot Water Coil: In buildings equipped with concealed ceiling or ducted split systems, this is the most common heating method, used in approximately 90% of installations. The hot water coil is selected based on the dimensions of the air outlet or return opening of each unit.

Even for inverter ducted split systems capable of heating via the compressor, the use of a hot water coil is recommended, as it significantly reduces electricity consumption and operating costs during winter.

During winter, hot water is supplied by the building’s central boiler or individual heating package. When it enters the hot water coil, it provides the required warm air for each unit. If an automatic air vent is not installed, it is necessary to bleed the coil manually at the beginning of each cold season.

b) Heat Pump: Another heating method involves ducted split systems equipped with a heat pump. However, in addition to high electricity consumption and insufficient heating capacity in some regions, heat pumps may cause the outdoor condenser to freeze during extremely cold weather.

c) Electric Heater Coil: Electric heater coils are rarely used in ducted split systems due to their very high power consumption. In this case, no hot water from a boiler or heating package is required, making this option suitable only for locations without gas piping or central heating systems.

DamaTajhiz; Guide to Selecting and Purchasing HVAC Equipment (Since 2004)

Applications of Ducted Split Systems

Ducted split systems are used for cooling and heating residential apartments, offices, villas, and similar spaces. They are considered a premium solution with electrical consumption comparable to, or sometimes higher than, conventional split air conditioners, depending on cooling and heating load calculations. In many cases, a single ducted split system replaces multiple split units within one property.

By using a ducted split system, independent cooling and heating can be provided for each unit, while significantly reducing maintenance and operating costs compared to central cooling systems such as chillers.

Experts at DamaTajhiz can recommend the most suitable ceiling ducted split systems from top brands based on precise calculations and the technical and economic conditions of each project.

Types of Ducted Split Systems

Ducted split systems can be categorized based on power consumption, electrical supply type, brand, and compressor type as follows:

1- Types of Ducted Split Systems Based on Energy Consumption

a) Energy-Efficient Inverter Ducted Split (Grade A): These units are designed to reduce electricity consumption and use variable-speed compressors that adjust output according to indoor temperature.

b) Conventional Ducted Split (Grade B): These systems operate with fixed-speed (ON/OFF) compressors, consume more electricity, and therefore fall under energy grade B.

2- Types of Ducted Split Systems Based on Power Supply

a) Single-Phase (220V) Ducted Split Systems: Available in capacities of 18,000, 24,000, 30,000, and 36,000 BTU/hr.

b) Three-Phase Ducted Split Systems: Required for capacities of 42,000, 48,000, and 60,000 BTU/hr.

3- Types of Ducted Split Systems Based on Compressor Type

a) Rotary Compressor: Offers lower noise, vibration, power consumption, and smaller dimensions compared to piston compressors.

b) Scroll Compressor: Provides higher efficiency and capacity, commonly used in ducted split systems above 36,000 BTU/hr.

c) Piston Compressor: One of the oldest compressor types, typically used in hot and tropical regions.

4- Types of Ducted Split Systems Based on Manufacturing Origin

- Iranian Ducted Split Systems: Popular local brands include DamaTajhiz, Gplus, Iran Radiator, SAM, and Royal Cool.

- Imported Ducted Split Systems: Well-known brands include Hisense, Tech Electric, LG, Green, Boimen, and Midea ducted AC units.

🔔 Note: All ducted split models offered by DamaTajhiz provide both cooling and heating functions, and upon request, can be equipped with a hot water coil for winter heating.

General Considerations for Selecting and Installing Ducted Split Systems

Some of the most important points that should be considered when selecting and installing various types of ducted split systems include the following:

- Proper selection of capacity, type, internal unit dimensions, and installation location of the ducted split system.

- Deciding whether to use a conventional ducted split or an inverter type (inverter systems, by means of soft start and variable compressor speed, reduce power consumption and prevent electrical shock to equipment during each compressor start-up). It is generally recommended to use inverter ducted split systems for capacities of 24,000 BTU and above.

- Correct and professional execution of air duct installation inside the false ceiling, based on engineering calculations and duct design, along with proper insulation of the copper pipes to achieve maximum efficiency and performance.

- To accurately determine the required capacity, it is recommended to send the latest architectural plans of the units and building floors via fax or email to the experts at DamaTajhiz Engineering Group, as a specialized consultation and sales center for cooling and heating equipment.

- Before selecting and ordering any ducted split system, in addition to considering the dimensions of the air handling unit or indoor panel, special attention should be paid to whether the required power supply is single-phase or three-phase, as well as the electrical current (A) consumption, taking into account the power capacity and specifications of the apartment’s electricity meter.

- Due to the importance of supply fan balance in ducted split performance and its direct impact on motor bearing lifespan, and in order to maintain dynamic balance of the fan, utmost care must be taken to ensure perfectly horizontal and level installation of the ducted split system at the installation site.

Additional Points

- Since ducted split systems typically use return air from the same unit, before placing and installing the system above the false ceiling or in any designated space, that area must be completely separated from other common building spaces (such as corridors above the false ceiling) using partitions or tiles. The ducted split should be installed in a position where only the return air of the intended unit or space circulates.

- During duct installation, the return air grille of the ducted split system should be located at the maximum possible distance from the supply air grilles.

- Considering the importance of indoor temperature sensing and thermostat on/off commands for controlling the ducted split fan operation (especially in brands that do not have a thermostat in the air intake path), selecting the thermostat installation location is of critical importance. Therefore, the thermostat should be installed at a height of 140 cm from the floor and in a location free from direct sunlight and direct airflow from the ducted split system.

- For vertical installation of copper refrigerant pipes, it is recommended to use one oil trap (OIL TRAP) for every 6 meters of pipe height.

- In general, the cost of installing air supply and return ducts inside units, as well as installing copper piping between the indoor duct unit and the outdoor condenser, varies depending on the distance and route length between these two sections. However, based on frequent inquiries from residential developers, an approximate estimate would be around 20% to 30% of the ducted split purchase price (this is only an approximate estimation).

What Is the Difference Between Inverter and Conventional Ducted Splits?

In conventional or fixed-speed ducted split systems, the compressor speed cannot be adjusted. This means that once the indoor temperature reaches the desired level, the compressor shuts off and then restarts again when the temperature changes. For this reason, these systems are known as ON/OFF ducted splits. In contrast, the inverter kit is a component that allows precise control of indoor temperature by adjusting the compressor speed according to the required temperature.

In other words, an inverter ducted split system can reduce the compressor motor speed once the desired indoor temperature is reached, while maintaining that temperature steadily. This results in lower energy consumption and keeps the compressor running continuously. Continuous operation also ensures uniform air distribution without temperature fluctuations. It should be noted that inverter ducted splits have lower noise levels and power consumption, while their purchase price is higher than conventional models.

Components and Internal Parts of a Ducted Split System

The indoor unit (evaporator or air handling unit) and the outdoor unit (condenser) of a ducted split system consist of various components, each responsible for a specific function.

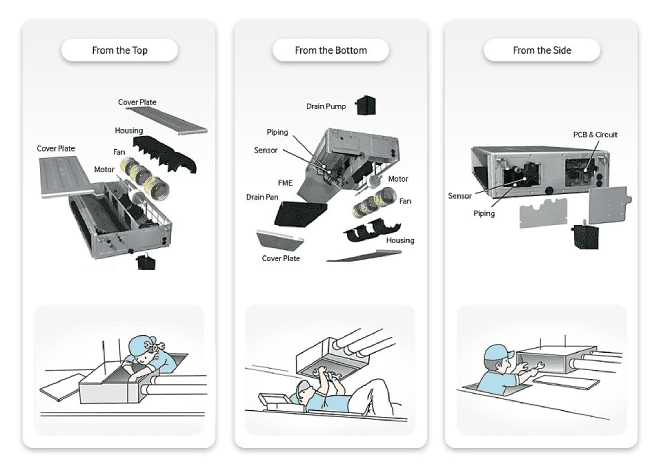

Main Components of the Evaporator or Indoor Unit

These components include the following:

- Evaporator casing, typically made of thick, high-quality galvanized steel sheets with high resistance to corrosion and rust.

- Evaporator coil, which contains the refrigerant.

- Fan and electric motor, which, when operating, transfer the cooling generated by the refrigerant toward the air outlet grilles.

- Drain pan, which prevents water droplets from dripping off the coil into the ceiling space.

- Air filter, located in the air outlet path, which improves the quality of air supplied to the rooms.

In the figure below, the internal components of the evaporator and condenser are shown from different views:

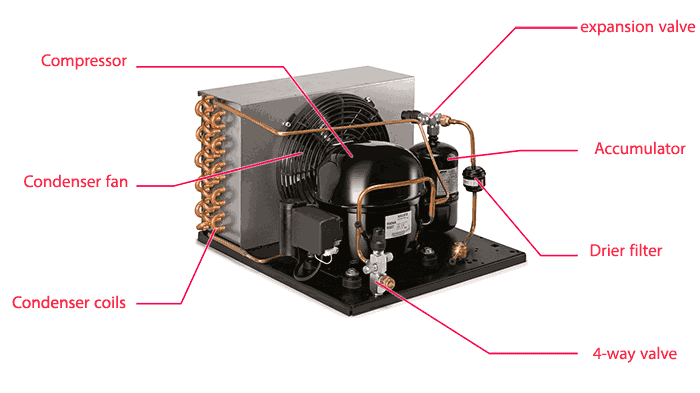

Main Components of the Ducted Split Condenser

Please note the following:

- Compressor, which is the core component of the condenser and is charged with R410a or R22 refrigerant gas, depending on the compressor type.

- Electric motor or condenser fan motor, connected to the compressor, which converts electrical energy into mechanical energy and causes the condenser fan to rotate.

- Condenser fan, which moves air across the condenser coil and fins.

- Expansion valve, which expands the refrigerant flow.

- Four-way valve, responsible for reversing the cooling and heating modes of the ducted split system.

- Accumulator, which acts as a temporary refrigerant reservoir, preventing liquid refrigerant from entering the compressor and regulating oil return to the compressor.

- Filter drier, a component that removes moisture, dust particles, and contaminants from the refrigerant cycle.

In the figure below, you can see the internal view of the ducted split condenser and its components:

Features of Concealed Ceiling Split Systems

These features include:

- Horizontal installation of the concealed ceiling split indoor unit within the minimum available space above the false ceiling

- High-quality cooling and air conditioning performance for each individual unit

- Easy and cost-effective maintenance and repair compared to central air conditioning systems (chillers)

- Elimination of extensive piping in floors and ceilings, reducing the volume of construction materials used

- Elimination of vertical ductwork and prevention of reduction in shared spaces of residential complexes

- Uniform distribution of cooling and heating through ducts installed within each unit’s false ceiling

- Independent operation for each apartment unit, resulting in lower maintenance costs and no need for a dedicated central system technician

Features of Tropical (Hot Climate) Ducted Split Systems

In general, tropical ducted split systems have unique characteristics compared to conventional ducted splits, including the following:

- The most distinctive feature of tropical ducted splits is the type of compressor used. These compressors are designed to deliver reliable performance even in very high outdoor temperatures. Scroll compressors are commonly used in this type of system.

- The evaporator and condenser coils in tropical ducted split systems are typically equipped with Blue Fin or Gold Fin coating. In very hot and humid regions, acidic salts are present in the air and rainwater, which can accumulate on coil surfaces and reduce system efficiency. Blue Fin or Gold Fin epoxy coatings prevent salt accumulation and moisture buildup on the coils.

- Although tropical ducted split systems are designed to operate in ambient temperatures ranging from 21°C to 57°C, they can also be safely used in moderate climate regions.

Advantages and Disadvantages of Ducted Split Systems

Ducted split systems offer several advantages as well as certain limitations. Being aware of these aspects before purchasing will help ensure a better selection and operating experience.

Advantages of Using Ducted Split Systems

The main benefits of purchasing and using a ducted split system include:

- Dual-function capability for cooling and heating in residential and commercial units

- Independent operation and energy costs for each unit

- Elimination of chillers, cooling towers, central boiler rooms, radiators, and related piping systems

- Ability to introduce fresh air when required by installing an air intake duct

- Dehumidification of humid summer air, air filtration, and reduction of indoor air pollution

- Compatibility with hot water heating coils and independent heating packages

- Suitable installation for large spaces with various applications

- Independent temperature control for different zones using thermostats and thermostatic air diffusers

- Easy operation and user-friendly control compared to central HVAC systems

- Acceptable service life throughout residential or commercial usage

Limitations or Disadvantages of Ceiling Concealed Ducted Splits

Despite their many advantages, concealed ceiling ducted split systems also have certain limitations. However, there are practical solutions to mitigate these issues, as explained below.

Lack of Independent Temperature Control for Individual Spaces

Typically, ducted split systems do not allow independent temperature zoning for individual rooms. All spaces connected to a single system receive the same conditioned air and are cooled or heated simultaneously.

Solution:

This limitation can be partially addressed through proper duct branch design and appropriate distance from the indoor unit. For full control, motorized or thermostatic dampers should replace fixed air grilles. Each damper is controlled by a room thermostat to regulate airflow according to the desired temperature.

This approach allows precise control of airflow and temperature for each room. However, installing such dampers significantly increases system costs. In such cases, alternative systems such as fan coil units combined with chillers are recommended.

Noise Level Considerations

Noise generated by ducted split systems can sometimes be bothersome, primarily due to the operation of the indoor fan during air intake. This issue can be reduced using the following methods:

Solution:

- Installing a return air grille or several meters of insulated flexible duct in the return air path

- Selecting systems equipped with low-noise components such as BLDC or variable-speed fans and motors

- Careful duct design considering pressure loss, airflow velocity, and proper duct sizing using duct calculation tools

- Installing the indoor unit away from bedrooms and living areas, such as above corridor false ceilings

- Selecting appropriate airflow capacity, or using two lower-capacity systems instead of one large unit to reduce noise and improve comfort

Coverage Area Limitations

In large or multi-story buildings, multiple ducted split systems may be required for effective air conditioning. Additionally, long copper piping between indoor and outdoor units can cause pressure loss, reduce efficiency, and impact building aesthetics.

Reduced Ceiling Height

Installing the indoor unit within a false ceiling reduces ceiling height by approximately 30 to 50 cm, which may affect interior space aesthetics.

Inefficient Heating Performance

During colder seasons, heating performance may be insufficient due to mismatched coil sizing, especially on very cold days.

Electrical Power Consumption

Ducted split systems cool or heat all connected spaces simultaneously. Therefore, conditioning only one area still results in energy use across all rooms, leading to higher electricity consumption compared to wall-mounted air conditioners.

Solution:

- Using energy-efficient inverter ducted split systems

- Minimizing the distance between indoor and outdoor units

- Installing two ducted split systems for separate control of living areas and bedrooms

In general, it is recommended to use each ducted split system in areas where occupants are present for most hours of the day.

These considerations highlight the need for careful evaluation when selecting ducted split systems and, in some cases, opting for alternative HVAC solutions.

Common Mistake in Installing the Indoor Unit of a Duct Split

In many projects, the indoor unit of a duct split system is installed before the execution of the false ceiling. In such cases, special attention must be paid to future maintenance access. There have been instances where, due to the lack of an access panel in the false ceiling, part of the ceiling had to be demolished for minor maintenance work, resulting in significant additional costs. Therefore, it is essential to allocate proper access space to the indoor unit during the false ceiling installation in each unit.

How Much Are the Cost and Electricity Consumption of a Ducted Split?

Overall electricity consumption depends on several factors, including cooling capacity, inverter technology, and usage patterns. Concealed ceiling ducted splits consume more electricity than wall-mounted units; however, using energy-efficient or inverter models significantly reduces power consumption.

Estimating monthly electricity costs is challenging, but continuous operation of a high-capacity non-inverter system will result in high electricity bills.

If the unit area exceeds 130 square meters, it is recommended to use two smaller ducted split systems—one for the living and dining areas (daytime operation) and another for bedrooms (nighttime operation)—to distribute energy use and reduce noise levels.

DamaTajhiz; Best Prices and Leading HVAC Brands (Since 2004)

Selecting and Purchasing a Ducted Split System

As mentioned earlier, selecting a ducted split system requires careful consideration of usable floor area, installation location, and required capacity for each residential or commercial unit. These systems are available in various cooling, heating, and airflow capacities. Therefore, determining the unit’s size and usage is essential before making a purchase. Additional factors such as single-phase or three-phase power supply, energy consumption, features, brand, and price should also be evaluated.

Another important consideration when purchasing a ducted split system is the type of supply air fan.

Evaluation of Supply Air Fans in Ducted Split Systems

In general, there are three main options for supply air fans in ducted split systems:

- Galvanized steel fans, which generate more noise but offer greater durability and higher static pressure for airflow through ducts.

- Compressed plastic fans, which are more affordable and quieter, but not recommended for cold climates due to potential heat damage over extended operation.

- Polyamide fans reinforced with carbon fibers, considered the best option, capable of withstanding temperatures up to 120°C while delivering excellent airflow and lower noise levels, though at a higher cost.

At the specialized DamaTajhiz group, technical specifications for hundreds of duct split models from reputable brands are provided with warranty, ensuring a smart and optimal purchasing experience for our valued customers (since 2004).

Duct Split Price

Duct split air conditioners vary in price depending on type, capacity, features, and brand. To select and purchase the appropriate duct split system, you should first determine the usable area and application of the unit, as well as the required cooling/heating capacity. For example, based on standard guidelines, a duct split unit with a capacity of 36,000 BTU/hr is recommended for middle or ground-floor units with an area of 100 square meters. The cost of a duct split system for a 100 m² area is also calculated based on this capacity.

It should be noted that all duct split units offered by the DamaTajhiz specialized group come with product identification codes and competitive pricing, with consumer-requested discounts already applied.

Comparison Table of Duct Split Brands Available at DamaTajhiz

Choosing the right duct split system requires a careful evaluation of technical specifications, pricing, and after-sales services. Brands such as Midea, Hisense, Boymen, Green, LG, and Gplus ducted ACs are among the top-selling options.

| Brand | Capacity Range | Inverter Technology | Compressor Type | Refrigerant | Warranty & After-Sales Service | Noise Level | Design & Dimensions | Country of Origin |

|---|---|---|---|---|---|---|---|---|

| Midea Duct Split | 24000–55000 | Available in most models | Rotary / Scroll | R410a | 5 years – Available | Acceptable | Varied | China |

| Hisense Duct Split | 18000–60000 | Available in most models | Rotary (mostly) | R410a | 5 years – Available | Acceptable | Varied | China |

| Gplus Duct Split | 24000–60000 | Available in most models | Rotary | R410a | 5 years – Goldiran (extensive and reliable) | Low noise (key popularity factor) | Compact | Iran (Goldiran assembly/design) |

| LG Duct Split | 24000–54000 | Available in most models | Rotary / Scroll (Original LG) | R410a | 5 years – Goldiran (previously, now other services) | Low noise (very popular) | Slim indoor unit & High Static | South Korea |

| Green Duct Split | 18000–60000 | Available in most models | Twin Rotary (Hitachi – mostly) | R410a | 5 years – Available (Pashm Shisheh Pars) | Low noise (commonly known as a quiet brand) | Compact and suitable for false ceilings | China |

| Boymen Duct Split | 18000–55000 | Various types: non-inverter (e.g., BTD series) and inverter (BID series) | Rotary (HIGHLY / GMCC) | R410a | 5 years – Available | Acceptable | Suitable dimensions for false ceilings | China |

Comparison Between Duct Split and Mini Chiller

Due to the frequent questions raised by residential developers regarding the comparison of purchase, installation, and operating costs of duct split systems with other HVAC solutions such as mini chillers (+ fan coil units) for each apartment, the sales experts of the specialized DamaTajhiz group emphasize—based on their calculations and practical experience—that an accurate cost estimation depends on several factors. These include the selected capacity and brand, technical specifications and features of the equipment, the floor area of the unit, installation location, and the system execution method, all of which play a decisive role in the outcome of this comparison.

However, under normal conditions and according to estimates, the total cost of purchasing, installing, and commissioning a duct split system is approximately 40% lower than the cost of purchasing, installing, and commissioning a mini chiller system (+ ceiling-mounted fan coil units) for a similar residential unit with the same capacity and brand.

- Regarding operating costs, which mainly include electricity consumption, periodic maintenance expenses, and refrigerant gas charging, there is no significant difference between the electricity usage and other operational costs of duct split systems and mini chillers. Nevertheless, when using a duct split system with a capacity higher than 3 tons of refrigeration, improper return air grille installation or incorrect duct design may cause noticeable air suction noise beneath the indoor unit.

Iranian Duct Split Systems

Over recent years, Iranian duct split systems have undergone notable improvements in quality through the integration of scientific knowledge and industrial production. This progress has enabled them to compete with long-established international brands, a fact that is clearly evident in Iran’s HVAC and heating industry.

Moreover, genuine warranties and reliable after-sales services offered by Iranian brands are among the key factors that attract customers and increase buyer confidence when selecting an Iranian duct split system.

It is worth mentioning that this positive transformation in the production of Iranian duct split systems began decades ago in the field of mechanical and HVAC equipment, including pumps, boilers, burners, fan coil units, chillers, and air handling units. Today, after several decades, the production of Iranian split and duct split air conditioners by brands such as DamaTajhiz, Gplus, Tak Electric, and Iran Radiator ducted split AC units has become widespread.

Golden Tips for Using and Maintaining Duct Split Systems

Below, we review the most important and practical 🌟 golden tips for using and maintaining duct split systems, helping you enjoy comfortable and quiet indoor air at home or in the workplace:

- If you are located close to a duct split unit, the sound of the supply fan and return airflow may be noticeable in some brands. Therefore, duct split systems should never be installed above the false ceilings of bedrooms, living rooms, or TV rooms. Accordingly, it is strongly recommended to install the indoor unit above the false ceiling of entrances, corridors, or circulation areas within the residential unit. (To prevent disturbing noise in bedrooms, it is advisable that the capacity of duct split systems installed above corridor ceilings does not exceed 2 tons of refrigeration).

- Never install the unit above the false ceiling of bathrooms, restrooms, or kitchens. In addition, if thermostatic air distribution dampers are not installed for each room (which is often overlooked), precise and independent temperature control for each space will not be possible.

- One of the limitations of ducted split systems is the requirement to install the outdoor unit (condensing unit) outside the building. Generally, installing a large number of condensing units for a residential complex or building—if not located on the rooftop—can negatively affect the building’s façade aesthetics. If rooftop installation is possible, in addition to checking the refrigerant suction capability from the indoor unit to the rooftop condensing unit at the required capacity, the cost of copper piping from the roof to the apartment and other implementation considerations must also be taken into account.

- The maximum allowable length of copper connecting pipes between the duct split indoor unit and the outdoor condenser ranges from 10 to 30 meters, depending on system capacity and the expert’s recommendation.

How Noisy Is a Duct Split System?

To determine the exact noise level of each duct split system, it is necessary to refer to the manufacturer’s 🗂️ catalog or the technical specifications provided on the specialized and reference website of DamaTajhiz.

In general, keep in mind that the indoor unit of a duct split system is installed inside the false ceiling and uses a large fan to distribute air to all rooms. As the air passes through multiple ducts into the occupied spaces, the evaporator fan noise may be audible within the unit. Therefore, it is recommended to install the indoor unit above corridor or entrance ceilings. It should also be noted that inverter duct split systems generate less noise compared to fixed-speed or non-inverter models.

Additionally, to reduce air suction noise from the return air grille beneath the unit, return air ducting can also be utilized.

How to Troubleshoot and Service a Ducted Split System

One of the most important aspects of maintaining a duct split system is selecting the appropriate system capacity based on the area of the space and ensuring accurate duct design in accordance with the building layout. It is also advisable to avoid frequent on/off cycling of the system throughout the day.

To extend the service life of ducted split systems, regular maintenance is essential, which includes the following procedures:

- Inspection and cleaning of the hot water coil

- Cleaning the blower in the condenser fan

- Cleaning the evaporator and condenser fins

- Checking the unit’s electrical power consumption

- Inspecting refrigerant levels and recharging if necessary

- Inspecting the ceiling-mounted frames of the duct split system

- Inspecting (and repairing if required) wire connections at terminal points

Please note that repair or periodic servicing of duct split systems is a specialized process and must be carried out exclusively by authorized service technicians or official after-sales service providers of the manufacturer.

Advantages of Purchasing Duct Split Systems from DamaTajhiz

Below are some of the key advantages of purchasing duct split systems from the specialized DamaTajhiz group:

1. Wide Range of Types and Models: DamaTajhiz offers an extensive selection of Iranian and international duct split systems suitable for various budgets and specific application requirements.

2. High Quality: The products listed on the DamaTajhiz website are supplied from reputable, high-quality brands, including globally recognized manufacturers such as Daikin, LG, Gree, and others known as leaders in the HVAC industry.

3. Competitive Pricing and Special Discounts: Due to direct cooperation with manufacturers and the elimination of intermediaries, DamaTajhiz provides competitive pricing. Seasonal and occasional special discounts are also among the benefits of purchasing from DamaTajhiz.

4. Fast and Secure Delivery: With an advanced logistics system and cooperation with reliable transportation companies, DamaTajhiz ensures fast and secure delivery of products to customers.

5. Technical Guidance and Consultation: DamaTajhiz’s experienced technical team is fully prepared to assist customers in selecting the most suitable duct split system based on their specific needs.

6. Comprehensive and Accurate Website Information: The DamaTajhiz website is designed to provide complete and accurate information for each product, including technical specifications, features, advantages, reviews, a comprehensive buying guide, pricing details, model comparisons, and essential tips for choosing the best option.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.