Steam Boiler

Steam Boiler is a device in which water is converted into steam using the heat generated from fuel combustion in the burner to meet various industrial needs. Below, the technical specifications, selection method, and purchase price of the steam boiler are provided.

Professional Guide for Selecting and Pricing Steam Boilers

Steam boilers are one of the most important pieces of industrial equipment, responsible for producing steam for industrial use and some facility systems. Boilers can be categorized based on their structural design (regardless of capacity, dimensions, and operating pressure) into two types: "Water Tube" and "Fire Tube," with Fire Tube boilers further divided into Wet Back and Dry Back types.

In Dry Back boilers, the ends of the 2nd and 3rd pass tubes connect to the same tube sheet. Due to the temperature difference in pass 2 (1000°c) and pass 3 (250°c), over time, this tube sheet may experience stress and eventually leak. Dry Back boilers also require insulation and periodic maintenance of the refractory material separating passes 2 and 3, which increases maintenance costs. Therefore, due to the importance of heat transfer surfaces and using the boiler’s back wall for heat exchange, Wet Back boilers are primarily used.

Review, Selection, and Pricing of HVAC Equipment

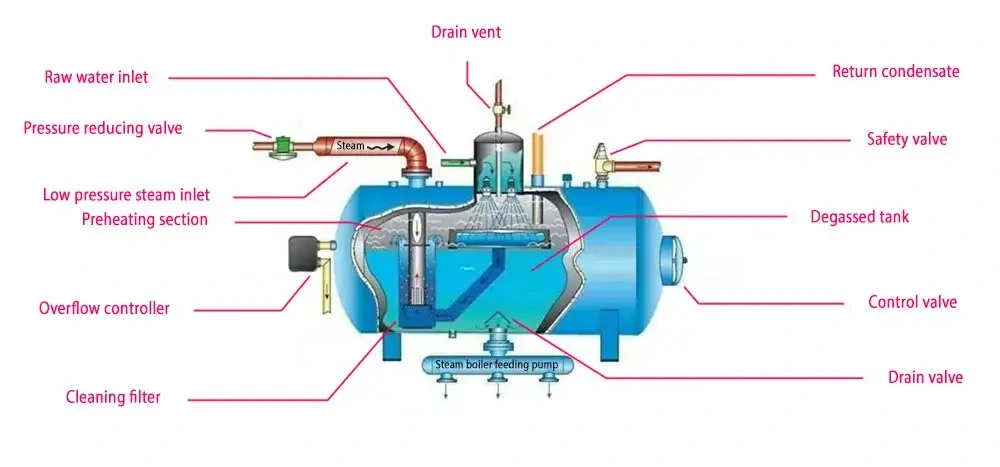

Components of a Steam Boiler

The main components of a steam boiler are:

- Combustion Chamber: The chamber where fuel and air mix and ignite. The energy from combustion provides the heat required to convert water into steam.

- Tubes and Shell: The boiler tubes and shell transfer heat from hot gases produced by combustion to the water inside the shell or tubes, converting it to steam. Tubes act as intermediaries transferring burner heat to water, producing steam. For heat exchange, straight or bent tubes are installed; hot gases pass through them, transferring heat to the tube walls without direct contact between gas and water.

- Burner: The burner mixes fuel (usually gas or diesel) with air and ignites it in the combustion chamber, generating heat and thermal energy for water-to-steam conversion.

- Thermostat: Used to control steam temperature and maintain the desired level. When the temperature reaches the user-set value, the thermostat signals the control unit to stop heat generation. Typically, 2 or 3 thermostats are used in steam boilers to ensure proper performance and safety.

- Safety Valve: Plays a key role in pressure control and safety. If pressure rises suddenly, the safety valve opens automatically to relieve pressure and protect the system. Multiple safety valves are installed to ensure full operational safety.

- Feed Pump: Supplies water to the system and varies according to boiler capacity and operating pressure.

- Pressure Gauge: Measures steam pressure. If the pressure exceeds the set limit, the pressure switch sends a signal to the control circuit to shut down the burner and feed pump. Typically, two or three pressure gauges are installed, including:

- Burner Pressure Gauge

- Burner Flame Pressure Gauge

- Safety Pressure Gauge

Types of Steam Boilers

There are two main types of steam boilers: Water Tube and Fire Tube boilers, each with significant structural and operational differences.

- Water-Tube Boilers

In water-tube boilers, water and steam flow inside the tubes while flame and combustion gases flow within the shell. These boilers are typically used for high capacity and high-pressure applications, such as power plants.

- Fire-Tube Boilers

In fire-tube boilers, flame and hot gases flow inside the tubes while water or steam surrounds the shell. Industrial fire-tube boilers often include 2-pass or 3-pass Dry Back types.

Comparison Table of Water Tube and Fire Tube Boilers

| Specifications |

Fire Tube |

Water Tube |

| Operating Pressure (bar) | Limited to 2–30 | Almost unlimited |

| Capacity (TON) | 30 TON | Almost unlimited |

| Suitable Fuel | All commercial fuels | Compatible with all types of fuel |

| Cost | Cheaper for the same applications | More expensive |

| Installation | Integrated | Can be installed and assembled on-site |

| Main Application | Industrial | Power Plants |

| Inspection Period (Months) | Every 6 months | Every 12 months |

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

Fully Corrugated Furnace and Tubes Effect on Increasing Steam Boiler Efficiency

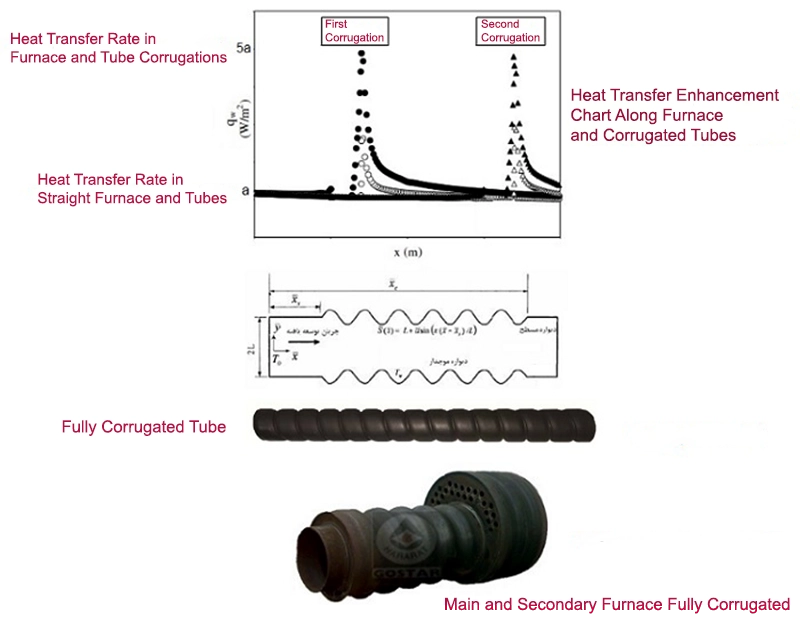

Since convective heat transfer (Convection) is of great importance for increasing the efficiency of steam boilers, additional heat transfer enhancement techniques are employed.

According to precise studies conducted on enhancing heat transfer by convection, known as V.H.T.E (Vortex Heat Transfer Enhancement), as the name suggests, this method is based on creating vortices in turbulent flow.

The V.H.T.E method is one of the widely used techniques, employing corrugations or ribs in furnace walls (Corrugated) and fire tubes Corrugated (Spiral) Tubes in steam boilers. By generating higher turbulence in the fluid flow, it increases convective heat transfer, resulting in improved heat exchange efficiency in steam and water tube boilers.

Recent research has shown that heat transfer inside the furnace and fully corrugated or ribbed tubes follows a highly complex pattern, to the extent that convective heat transfer at the corrugation sites of fully corrugated tubes can be almost five times higher than that in smooth tubes!

Radiative heat transfer in the furnace and corrugated tubes should also increase due to the larger surface area and the many ribs. These two factors—enhanced convective heat transfer through V.H.T.E and increased radiative transfer due to numerous ribs—significantly improve heat transfer efficiency in hot water and steam boilers.

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

Purchasing a Steam Boiler

All standard steam boilers are manufactured according to boiler and pressure vessel regulations prepared by the American Society of Mechanical Engineers, as their pressure generally exceeds 15 Pascal. Boiler selection is based on load combination (flow and steam pressure required for processes, steam-consuming equipment, and steam required for hot water generation).

To select and purchase a suitable steam boiler, first determine the required capacity and operating pressure. In Damatajhiz’s specialized collection, technical information for dozens of steam boiler models from reputable brands with original warranty is provided to ensure an optimized and intelligent purchase experience.

Considerations When Purchasing and Installing a Steam Boiler

- Accessibility to various parts of the boiler and the presence of handholes and manholes in different sections for periodic maintenance and possible replacement of defective tubes.

- Consideration of the full dimensions of the boiler with its accessories and their weight for entry into the boiler room and installation on site.

- In industrial boiler rooms using steam boilers, water softeners or descalers and deaerators must be installed in the feedwater path, since the maximum allowable water hardness for steam boilers is 20 PPM.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

Steam Boiler Price

In Damatajhiz’s specialized collection, check steam boiler prices and select the most suitable option. Prices vary according to model, capacity, and brand. The listed prices are updated and include consumer-requested discounts, as well as the best-price guarantee.

Key Factors for Extending Steam Boiler Lifespan

- Design and manufacture of the boiler according to approved drawings and internationally accepted standards.

- Use of alloy steels and standard fire tubes mentioned above, sufficient tube heat transfer surface, number of boiler passes, tube-to-tube plate connections using mechanical methods instead of welding, etc.

- Selection of a burner with calculated capacity suitable for boiler heating (maximum 20% above boiler capacity).

- Proper adjustment of the burner flame (blue flame and correct longitudinal flame flow in boilers).

- If using a diesel burner, the type and spray angle of fuel from the nozzle must be determined according to the combustion chamber diameter and length, as recommended by the boiler manufacturer.

- Accurate calculation and implementation of the chimney regarding diameter and draft height according to combustion air volume.

- Conducting inspections and periodic maintenance, especially regarding burner combustion in steel hot water boilers, and checking proper operation of control surfaces, safety valves, thermostats, etc.

Prepared and compiled by the Engineering Department, Heating Equipment and Boiler Room Section, Damatajhiz

- Dear User:

- We appreciate your trust in the technical advice of Damatajhiz experts. Please note that the selection of a product brand is generally determined by the buyer based on experience, brand strength, services, and price. However, for steam boilers, users often choose popular brands such as Hararat Gostar due to quality, price, and after-sales services.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Georgia, Kuwait, Uzbekistan, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, and Doha Amman, Sulaimaniyah, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, etc.) in the shortest possible time. Furthermore, you can ask any question in the HVAC area of expertise and receive a free consultation from our professional team members by calling +98-930-288-0251 or sending a WhatsApp message to this number.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.