Level Control Equipment

Level control equipment is used to monitor and control fluids in tanks and storages. In the following content we have provided information about the price, how to choose, technical specifications, etc. of level control equipment, so stay put.

Level Control Equipment Expert Buying Guide and Price List

If you want to use level control equipment to measure the height of the surface and prevent the tank from overflowing, and you do not know what level control equipment to use, with what model, brand, price, and specifications, Stay with us as answer all your questions regarding the price, technical specifications and the best types of level control equipment.

Level control, or in other words, measuring the height of the fluid level, is done to prevent overflow in tanks and some devices.

Measuring the height of the fluid inside the tank and controlling it by connecting and disconnecting the inlet and outlet flow to the tank is of great importance. For this reason, two or even three types of measuring devices are used to estimate tank fluid levels accurately.

Among the equipment used to control and measure the level, we can mention the level indicator, level switch, level meter, and level sensor.

Review, Selection, and Pricing of HVAC Equipment

Level Indicator

A level indicator placed on the tanks can show the height of the materials inside the tank.

Level Switch

Level switches, which have a level measurement sensor, are used in many industries to control and measure the level of fluids from the bottom of tanks to the top of the fluid level.

By sending ON-OFF commands to electronic circuits, the level switch can control various equipment (electro pumps, solenoids, etc.).

To know the level and apply control, we need tools that, if the level reaches the required values, the corresponding switch will issue the command to turn off and on the current. Level switches can be divided into the following types:

Float Level Switch

In float level switches, the change of the liquid level causes the movement of the float inside the device chamber, which is transferred to the mercury switches through the communication levers and the rotation of the axes through the holding arm.

This causes the movement of the mercury inside the key and it turns from one side to the other, which ultimately causes our current to flow between its electrodes. This way, sending ON-OFF commands to electrical circuits is possible.

Features of the Float Level Switches

The following are some of the features of the float level switch:

- Continuous and regular control of the fluid level.

- It is installable in places with high temperatures.

- The ability to install in places that require a high-reliability factor.

- With the ability to install in dangerous places that require a license and performance certificate.

- No need for continuous repairs and service.

- Having complete sealing using the seal bellows mechanism.

Ultrasonic Level Switch

Ultrasonic level switches are used in various industries for water purification and pump control in measuring currents passing through open channels and the level of very viscous liquids close to solids.

These sensors emit high-frequency acoustic waves (20kHz to 200kHz) that are reflected in contact with the fluid and detected by the transducer.

Vibrating Level Switch

Vibration level switches control the level of liquids and powdered solids in various industries. They can measure the level of excellent powders and granular solids.

They can measure the level of very fluid powders and electrostatic materials by determining the appropriate vibration frequencies and adjusting the appropriate sensitivity.

The vibrating switch starts to vibrate with a defined frequency in normal mode. When the desired fluid reaches a certain level, the change in the domain environment causes the value of the vibration frequency to change. Finally, the desired switch output command is issued.

Paddle Level Switch

Paddle level switches are used to measure the level in tanks of powdered and granulated solids such as granules, sand, etc. In paddle switches, a metal paddle is connected to an electric motor, which rotates until the material's surface reaches the metal paddle.

The paddle stops moving as soon as the material's surface reaches where the paddle is installed. The pressure caused by the paddle stopping causes the motor to move from its axis. Finally, the switch valve commands the whole or empty tank level.

Factors to Consider When Choosing Paddle Level Switches

The following are 3 of the most important factors you should consider when buying a paddle level switch:

- Circuit feeding type

- Shaft length and its connection type

- Engine speed (rpm)

Capacitive Level Switch

Capacitive level switches continuously and discretely have the ability to monitor the maximum and minimum values in the tanks. Capacitive level switches are used to determine the level of powdery, granular, or flake materials or to determine the border points of two materials with different densities in tanks.

In a capacitive level switch, the greater the amount of material between the electrode and the tank's surface, the greater the capacitor's dielectric property. Based on that, an output proportional to the tank's height is obtained.

Among the advantages of determining the level through capacitive level gauges are the absence of moving parts and the stability of performance over a long time.

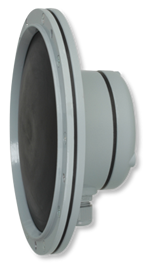

Diaphragm Level Switch

Diaphragm level switches are used in various industries to measure the level of liquids, especially powder and solids.

Diaphragm level switches mechanically without the need to be fed through the pressure applied to the membrane or the thin membrane of the diaphragm and the like can, by transferring this pressure to a micro switch, send the suitable output for monitoring the tank's full and empty status.

Advantages of Diaphragm Level Switches

The following are 2 of the most important advantages of the diaphragm level switches:

- Ease of use in special functional conditions (high temperatures or explosive environments)

- This sensor does not need a power supply.

Capacitance / Admittance Level Switch

Capacitive / admittance level switches are for measuring and determining a wide range of solid materials, organic liquids, and slurry. These sensors can measure with a dielectric constant of at least 1/1 (soot and ash) and up to 88 (water).

Sludges, slurries, dehydrated materials, sewage (with a dielectric constant of approximately 50), and liquid chemicals such as quicklime (with a dielectric constant of approximately 90) are measurable with these sensors.

The admittance level switch has a guard section, so the circuit determines only the change of admittance current between the active section and the tank wall.

Level Transmitters

Level transmitters are for measuring one of the physical parameters and converting it into a standard signal (such as 4 to 20 milliamps or zero to ten volts) in the processes of pressure control, determining the level of the height of the material inside the tank, etc. and transfer It is used for control and monitoring to a distant place such as the control room.

The output obtained from level transmitters is usable in displays, PLC systems, and all control equipment.

Today, the transmitter is widely used in oil, gas, petrochemical, steel, cement, foundry, pharmaceutical, medical engineering, and generally any system that requires industrial automation. Level transmitters can be divided into the following:

Floating Level Transmitters

Floating level transmitters are suitable for measuring water level, diesel oil, coal storage, etc. In floating-level transmitters, when the float moves, the machine's gear connects to the float, which causes spring movement. It displays the size of the surface according to a scale and finally produces an analog signal.

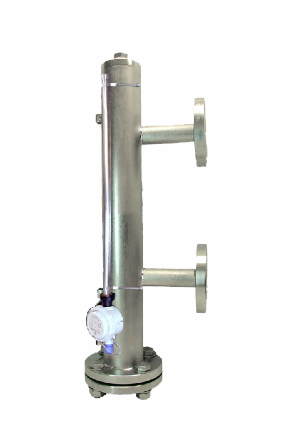

Magnetic Level Transmitters

In a magnetic transmitter tube, a magnet is placed inside a float on the liquid's surface. With the floating motion of the rotation of the magnetic strips outside the tank and considering the color difference on both sides of these strips, you can easily find out the position of the liquid level in the tank.

The magnetic level transmitter measures the level (height) of liquids in tanks. In this method, it is possible to read the height locally and transmit the signal to another point. Also, this method has advantages such as increasing the safety factor, reducing maintenance and long-term operational costs.

Smart Level Transmitter

Advantages of the Level Transmitters

The following are some of the advantages of the level transmitters:

- Temperature range (temperature range)

- Tank pressure or line pressure

- Number and type of desired output

- environmental conditions

- Measurable height

- Connection type

- Fluid density or viscosity

- type of fluid

- Accuracy of equipment

Level Control Sensors

A level control sensor is a sensing element that converts physical quantities, such as pressure, heat, humidity, temperature, etc., into continuous analog or digital values.

Sensors are used in all kinds of measuring devices and the types of level control sensors are divided into the following groups:

Optical Level Control Sensors

Optical level control sensors detect the level of liquids such as alcohol, ether, distilled water, various acids industrial oils, etc.

These sensors operate based on sending modulated infrared waves and receiving refracted waves from the prismatic tip of the sensor. The sensor's tip comes into contact with the liquid.

The refraction angle of the waves changes and they do not reach the receiver and the output of the sensor changes. The body of these sensors is made of stainless steel. Their probe's material is acrylic, resistant to various liquids and acids.

Magnetic Level Control Sensors

Magnetic level control sensors detect the liquid level in tanks at one or more specific points. They are installed vertically in the tank without a power source.

Magnetic level control sensors include a polyamide float that moves along with the liquid in the tank. The float movement along the rod triggers the switches inside the rod and activates the device's output.

Capacitance Level Control Sensors

Capacitive level control sensors (sensors without contact and electrical contact) are a type of proximity sensor used to detect the presence of materials in metal tanks. Capacitor level control sensors are suitable for level control in tanks filled with powdery, liquid, and granular materials.

Despite the similarity of these sensors with inductive sensors, capacitance level control sensors can detect non-metallic materials (glass, paper, plastic, liquids, cloth) as well as metallic materials. Capacitance level sensors are also usable beside generators to control machines' program status for counters and detect almost all metallic and non-metallic materials.

They are also used to determine the water level in plastic bottles, detect opaque and black objects, detect powder inside bottles, detect wires with copper cables, etc.

Types of Capacitance Level Control Sensors

There are two types of capacitance level sensors:

- Capacitive level control sensors with the coated probe: Suitable for conductive materials such as water, iron oxide, aluminum oxide, etc

- Capacitive level control sensors with uncoated probes: Suitable for materials with high electrical resistance, such as cement, clay, plaster, various oils, plastic granules, ceramic powder, etc

Buying Level Control Equipment

On the DamaTajhiz HVAC store, technical information and prices for all types of level control equipment, including level transmitter, level control, level switch, etc. from popular brands such as Antini, Rosemont, Anders Hauser, etc., have been presented for you to enjoy a good and smart shopping experience.

All products in the DamaTajhiz HVAC store come with the original warranty and the discounts desired by customers have already been included. If you have questions about level control equipment, you can contact us through email or WhatsApp.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet With You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.