Circulator Pump

A circulator pump is used to circulate heating and cooling water in building HVAC systems and cooling towers. Below, the technical data, flow rate estimation, selection guideline, and purchase price of various types of circulator pumps are provided.

Circulator Pump Expert Buying Guide and Price List

In general, a circulator pump circulates cold or hot water in the building's air conditioning or central heating systems from the place of production to the places of heat exchange in cooling and heating devices. They are usually used in small and medium-sized buildings with a lower speed (up to about 1450 RPM).

In other words, after providing hot water in the central heating boiler and also providing cold water in the refrigeration cycle of the chiller (or other cooling systems), a circulating pump circulates this water in the pipes to the radiators, fan coils, air generator coils, etc.

Review, Selection, and Pricing of HVAC Equipment

Circulatory pumps are only used to circulate the water of the cooling and heating system in the circuit of this equipment, so the water is riding on their impeller, and they do not need the ability to suck water from lower levels (such as irrigation and water supply pumps).

Types of Circulator Pumps

Depending on the installation location, there are two main categories of circulator pumps namely inline circulatory pumps and end suction circulation pumps. Each type has its advantages and disadvantages, and the choice depends on the specific requirements of the application:

Inline Circulator Pump

Inline circulator pumps are known for their compact design, while they are installed in-line. This means that the flow path passes through the pump and they are suitable in housing conditions of limited space.

This design also results in lower noise levels and vibration when compared to end suction pumps and they are easily accessible.

However, inline circulate pumps have their downsides, as they tend to have lower flow rates than end suction pumps.

/inline-circulator-pump.webp)

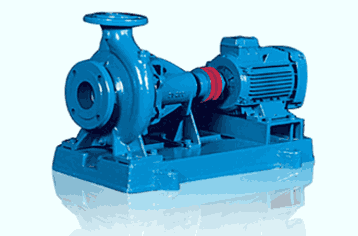

End Suction Circulator Pump

End suction circulator pumps have a different design where the suction inlet will be on the end of the pump casing. End suction pumps are installed vertically and/or horizontally but need extra pipelines and fitting.

The end suction pumps are usually characterized by higher flow rates and lower pressure drop compared to inline pumps.

However, end suction pumps are less compact, more noisy, and have complicated assembling and maintenance.

/end-suction-circulator-pump.webp)

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

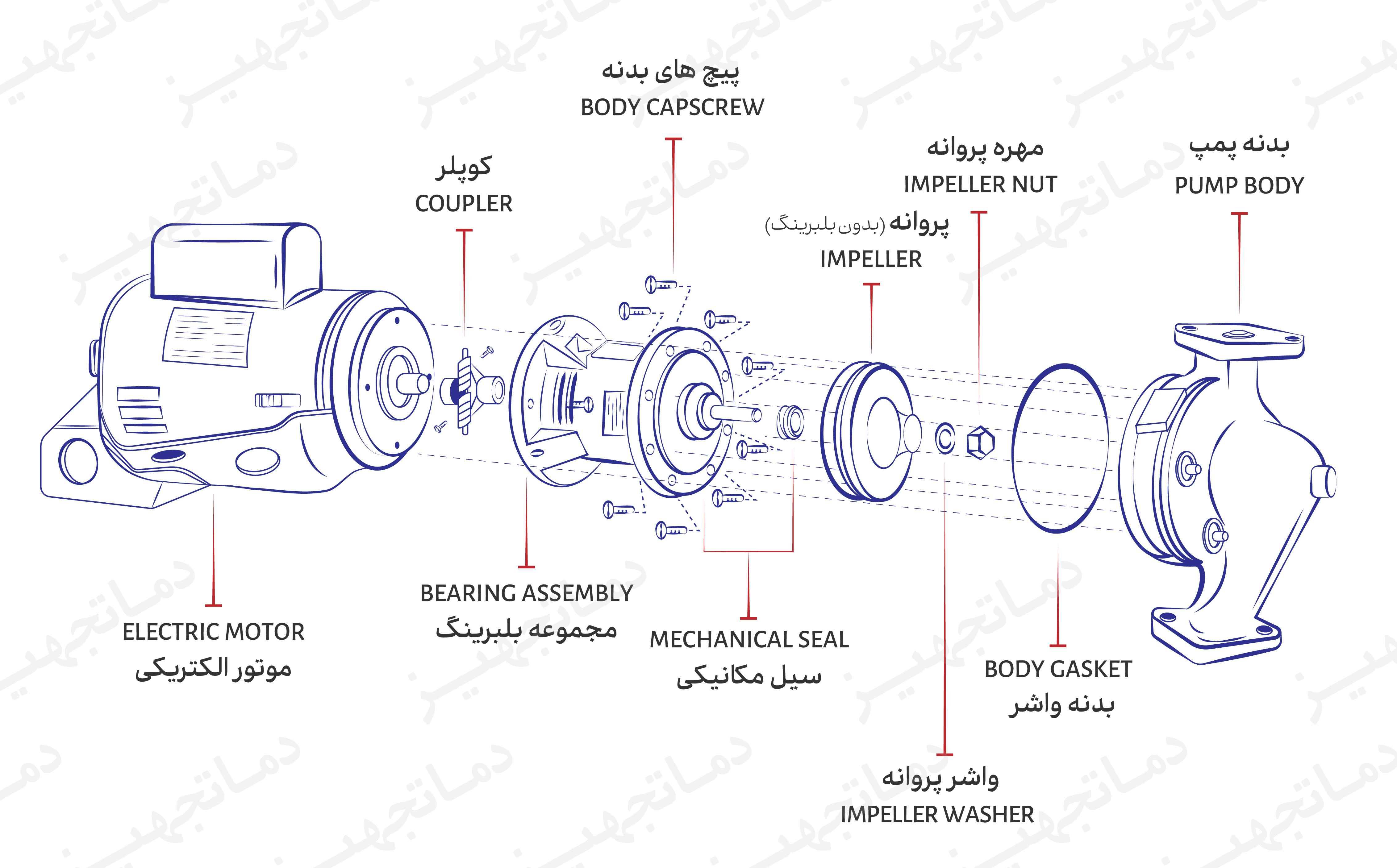

Circulator Pump Components

The components of the circulator pump are as follows:

Circulator Pump's Electric Motor

The electric motor plays a key role in the operation of the circulation pump and is responsible for converting electrical energy into mechanical energy to move the pump impeller. These motors can work with single-phase electricity (at low powers) or three phases (at high powers).

The rotation speed of the motor is between 1450 and 2900 RPM, which is selected based on the system requirements and the model of the electro pump. This engine provides the necessary driving force to move fluid in heating, cooling, or air conditioning systems.

Circulator Pump's Coupling

Coupling is responsible for connecting the electric motor to the pump shaft. This piece plays an important role in transferring mechanical power from the motor axis to the pump impeller axis and can also absorb shocks or fluctuations caused by the motor, which helps to increase the useful life and efficiency of the pump.

Couplings are usually made of cast iron or brass, which prevent the erosion and burning of electric motors.

Circulator Pump's Shaft

The main role of the shaft is to transfer the rotary motion from the electric motor to the pump impeller. This part is usually made of steel or stainless steel to resist corrosion and wear.

The shaft is supported by bearings that help reduce friction and ensure smooth movement of the shaft, thereby increasing the useful life of the pump. The shaft is directly connected to the impeller and turns the rotation of the motor into the driving force necessary for the fluid flow in the system.

Circulator Pump's Bearings

Bearings in circulator pumps are responsible for keeping the axis (shaft) in place and preventing its unstable movement, as well as minimizing the friction between the axis and the pump body.

Bearings are usually made of bronze, each bearing has a special groove for lubrication, which provides constant and continuous circulation of oil on the surface of the bearings. These grooves help reduce friction and prevent overheating, contributing to optimal performance and longer pump life.

Circulator Pump's Mechanical Seal

This part is responsible for preventing fluid from leaking out of the pump and also preventing air from entering the pump. A mechanical seal or felt bowl is placed between the shaft and the pump body and prevents liquid leakage at the connection points by creating a tight seal.

The mechanical seal plays a very important role in maintaining the internal pressure of the flowing fluid in the pump and its efficiency, and it helps to prevent breakdowns caused by leakage and corrosion of the pump. In high-quality circulator pumps, the seals or seals are usually of the Borgman type from Germany or BT from Italy.

Circulating Pump's Impeller

The impeller is the most important component of circulator pumps whose task is to transfer and move fluid at the required pressure or head.

By converting the mechanical energy of the engine into kinetic energy, this rotating part moves the desired flow rate of the fluid and directs it from the inlet to the outlet of the pump with pressure and also prevents air from collecting in the pump felt bowl.

Impellers are made of different materials such as steel, brass, compressed plastic, and aluminum alloy according to the need, each of which is selected depending on the application, corrosion resistance, flow rate, and pressure required by the pump.

The type, material, and dimensions of the pump impeller directly affect the transfer of flow volume and pressure or the head of the circulatory pump.

Circulator Pump's Casing

In circulator pumps, the body acts as a housing that houses other pump components. This part is usually made of corrosion-resistant materials such as cast aluminum alloy, cast iron, or steel to withstand pressure and different working conditions.

The body of this pump also provides the fluid flow path and helps to direct the fluid from the inlet to the outlet of the circulatory pump, which is necessary for the optimal performance of the pump.

Circulator Pump's Unions

The final piece, which is essential for installing any inline circulator pump on the return pipes of the heating system and the outgoing pipes of the cooling system in engine houses, is called the gear nut.

The spool nut of each inline pump with the size of the diameter of the inlet and outlet pipes of the circulation pumps is installed on the sides of the pump on the corresponding pipe.

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

Circulator Pump Flow Rate (GPM) Estimation

In general, at each section of the heating system, by dividing kilocalories by 2500, the flowrate (GPM) or circulating water volume of the same section of the heating system is obtained (to calculate the diameter of the pipes and the required flowrate of the circulator pump).

Hot Water: Kcal / 2500 = BTU / 10000 = GPM

Also, by dividing the kilocalories of each section of the cooling system by the number of 1250 flowrate (GPM) or the volume of water circulating in the same section of the cooling system is obtained (to calculate the diameter of the pipes and the required flowrate of the circulatory pump).

Cold Water: Kcal / 1250 = BTU / 5000 = GPM

For example, if approximately 100 kilocalories of heating are required per square meter of the building’s net usable area, the circulation pump flow rate (GPM) for the heating system can be roughly calculated by multiplying 100 by the total net area and then dividing the result by 2500.

Similarly, to estimate the required circulation pump flow rate (GPM) for the cooling system, if each square meter of the net usable area requires about 100 kilocalories of cooling, simply multiply 100 by the total net area of the building and divide the result by 1250 to obtain the required GPM for the cooling circulation pump.

Here are the 8 points to keep in mind when calculating the pressure of a circulator pump:

- One of the most important and decisive factors in the correct calculation of the required head or pressure of circulatory pumps is to pay attention to the natural flow of water inside the vertical pipes.

- This means that the only function of circulation pumps, which are usually used in closed cooling and heating systems, is to compensate for the frictional pressure drop of the water flow in the pipes, fittings, valves, and coils. Therefore, the required pressure of these pumps is usually much less than the pressure of the water supply pump of the same project, and this effectively reduces the power of the circulator electro-pump motor.

- Suppose the reverse piping method is used in medium and large buildings. In that case, it is possible to achieve the minimum required power of the circulator pump, as well as the most suitable uniform distribution of water flow in the piping can be achieved.

- When calculating the pressure of the cooling tower pump, due to the open path of water and the presence of natural flow in the return path of the water to the condenser, the same method of calculating the pressure of the circulate pumps should be used.

- If circulating pumps with 2900 RPM are used in small and medium-sized buildings, the vibration of the pump and the strong flow of water in the pipes will interrupt the comfort of the residents.

- If the circulation pump does not provide the circulating water pressure, the cold or hot water will not be able to pass through the pipes and reach the radiator, fan coil, or other cooling and heating devices.

- Also, Suppose there is no volume or flow rate of the relevant pump. In that case, the volume of water will not reach the device, and the cooling and heating device will be able to provide cooling and heating with a capacity lower than its actual capacity. Therefore, when choosing the required circulator pump, you can contact the sales experts of DamaTajhiz HVAC Group for better results.

- Suppose the pressure of the circulatory pump is over-calculated. In that case, there is a possibility of water overflow from the open expansion source of the heating/cooling system on the roof of the building.

Considering that many buildings have a total floor area of less than 2,000 square meters, determining the type or model of the water circulation pump for the heating system of those buildings does not require a complex calculation.

As a general guide based on the model of relative pumps, we present the popular Semnan Co. circulator pumps for buildings up to 7 floors.

Circulator Pump Friction Head Calculation

To calculate the circulator pump head, two main parameters must be considered: Pressure drop in the pipes and fittings + length.

In circulatory pumps the vertical height at which water must be pumped up or down from the engine room to other floors of the building, as well as the pressure drop in the piping and fittings, greatly impact the calculation of the pump head.

The vertical height (due to the return of water to the same height) is usually not considered an independent parameter. The main focus is on calculating the pressure drop of the pipes, fittings, and heat transfer coils of installation equipment such as coils, fan coils, air conditioners, and even boilers and radiators...

To calculate the circulating pump head, you must consider the total pressure drop along the piping route, + the pressure drop of the fittings, heat transfer coils, and other heating and cooling equipment in each route. The general formula for calculating the head of the circulate pump is as follows:

H = H-pipe + H-junctions + H-equipment

- H: Total head of the circulator pump

- H-pipe: The pressure drop due to the length of the pipes is usually calculated using specific tables and standards for each type of pipe. In general, this pressure drop depends on the length and type of pipes.

- L: Length of the pipes.

- L-effective: The effective piping length which is considered to be 50% of the total piping length.

L-effective = L × 0.5

Assuming that the pressure drop in the water flow of the pipes according to engineering tables is about 2.5% of the path length.

H-pipe = L-effective × 0.025

- H-junctions: For joints such as elbows and valves, there is usually a pressure drop coefficient that is calculated based on the number and type of joints. This pressure drop is added to the equivalent length of piping.

- Elbow pipes: For each 90-degree elbow pipe, a pressure drop of 0.52 units (feet or meters) is usually added to the length of the pipe.

- T: For each T junction, a pressure drop of 1.77 units is usually added to the length of the pipe.

- H-equipment: This pressure drop is related to equipment such as radiators, coils, boilers, and other system components. The value of this pressure drop is usually extracted from the equipment specifications or standard tables.

Note: Cooling tower pumps, which are responsible for the flow and movement of water from the condenser of water chillers to the cooling tower location on the roof or building site (based on the location of the cooling tower installation), are considered circulator pumps with a speed of 1450 RPM in pump head calculations.

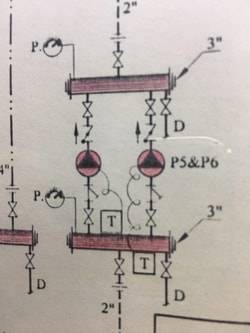

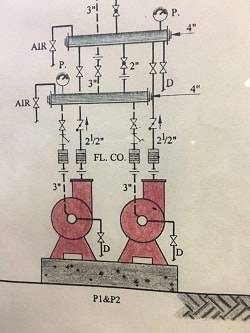

Circulator Pump Installation Location

Circulator pumps are usually installed in the return water circuit of cooling or heating systems. In other words, they are placed before the central heating boiler in the heating systems and before the chiller in the cooling systems so that the water output of the circulatory pumps in the heating systems enters the boiler and then is distributed to the radiators and fan coils.

Then, the water output of the circulating pump enters the chiller evaporator and then enters the fan coil and air conditioner coil. To return the unused hot water in the building's hot water piping, it is necessary to install the hot water return pump before the coiled or double wall tank on the hot water return pipe.

Usually, the hot water return pump used for the double-walled tank or even the spiral tank is considered to be a 1-inch or 1/4-inch Grundfos, DAB, or WILO brand inline pump.

Executive Recommendations for Installing a Circulator Pump

According to the recommended standards of facility engineering, in buildings with 8 or more units, it is necessary to consider a "reserved" circulator pump with the same power, head, and flow rate as the main pump.

It is better to separate the function of the hot water circulatory pump of the heating (or cooling) system of the building with the circulation path of the hot water feeding the boiler in the source of the coil; for each of the two paths, for better exploitation in different seasons of the year, a separate circulating pump should be installed.

In general, the off-on operation of the circulation pumps is done by the wall thermostat installed on the return water pipe of the heating (or cooling) system.

The temperature setting of the wall thermostat installed on the suction pipeline of the circulatory pump should usually be about 5 degrees Celsius lower than the set temperature of the submerged thermostat of the building's engine room hot water boiler.

It is necessary to install a filter in the suction pipe of all pumps and install a shock absorber in the inlet and outlet pipes of end suction circulator pumps. The following diagrams will help you install your circular pump correctly:

Inline Circulator Pump Installation Diagram

End Suction Circulator Pump Installation Diagram

In order to examine and then buy the most suitable circulator pump, you must first determine the brand and required capacity.

For this reason, the DamaTajhiz HVAC website has gathered specialized collection and technical information on dozens of circulation pumps from reputed brands, along with their eligible guarantee for you to enjoy the good feeling of optimal and smart shopping.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

The Parameters to Keep in Mind When Selecting a Circulator Pump

When choosing the circulator pump needed for the project, check the following specs carefully:

- The amount of head and flow of water in circulation required by the system

- Inline or End Suction pump

- Circulator pump brand and model

- Pump motor power and speed

- Rib/flange connection

- The diameter of the inlet and outlet pipes of the circulation pump

Buying a Circulator Pump

Water circulator pumps usually have inline and end suction pumps (usually used in small or medium-sized buildings), 1450 round, and have less electrical power than similar water supply pumps. Inline pumps are installed on the pipe with gear or flange connection, and end suction pumps on a suitable and leveled chassis and bolts with rubber shock absorbers.

In order to choose and buy a circulatory pump easily, you must first determine the brand and required capacity. On the site of DamaTajhiz HVAC Group, the technical information of dozens of models of circulation pumps from reputable brands with original warranties has been presented so that you, dear customers, can enjoy the good feeling of optimal and smart shopping.

Also note that in the specialized HVAC group of Damatajhiz, all the circulating pumps are only sold in bulk. Therefore, if you want to wholesale any of these products, feel free to contact us.

Circulator Pump Price

The price of circulator pumps varies according to the variety of models and brands available in the market.

You can browse all types of circulation pumps at the best price; it should also be noted that the prices presented in the DamaTajhiz are all up-to-date, with an elite discount already included in these prices. Therefore, the best price for all types of circular tanks is guaranteed for wholesale purchase.

Dear user:

While thanking you for the trust you have in the technical opinions of DamaTajhiz sales experts, it should be noted that the determination and selection of the desired product brand based on history, brand strength, service, and product price are ultimately determined by the buyer. But in circulating pumps, most of the users and buyers choose and buy best-selling brands such as DamaTajhiz and Semnan Energy according to their quality, price, and after-sales service.

Because the specialized group of DamaTajhiz HVAC Group provides all kinds of circulation pumps in the Middle East region, if you need a pool pump for any of the countries in the region, you can place your purchase order with confidence, product guarantee, and reasonable price. Please leave it to our sales experts.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.