Cast Iron Boiler

A cast iron boiler is one of the commonly used pieces of equipment in central boiler rooms, designed to supply domestic hot water and serve space heating systems. Below, the technical specifications, capacity calculation, selection criteria, and price list of cast iron boilers are presented.

Cast Iron Boilers Expert Selecting Guide and Price List

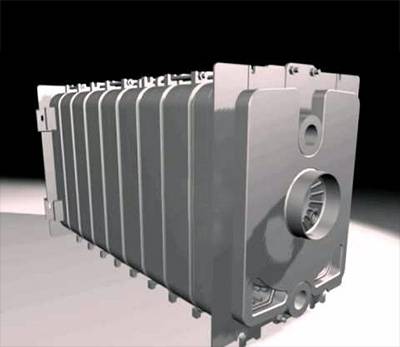

Cast iron boilers are among the best-selling and most commonly used types of boilers in central boiler rooms. Unlike steel boilers, they are manufactured in sectional (modular) form with different capacities and are typically applied in low-working-pressure systems, such as residential heating installations. They are also considered an ideal replacement for large and heavy steel boilers.

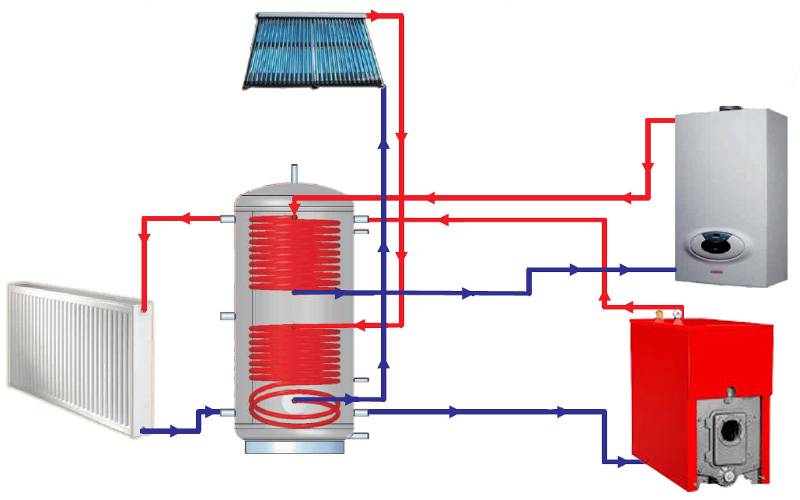

In general, all types of boilers, either cast iron or steel, installed in engine rooms, provide hot water for heating equipment such as radiators, fan coils, swimming pools or hot tub heaters, and other devices with hot water consumption, using the thermal energy of the boiler burner.

Review, Selection, and Pricing of HVAC Equipment

The operating pressure and heat absorption efficiency of cast iron boilers are usually lower than those of steel hot water boilers. However, the use of cast iron hot water boilers is more common due to their sectional design, which makes them easier to transport and install, more affordable, and simpler to maintain or replace defective sections during their service life.

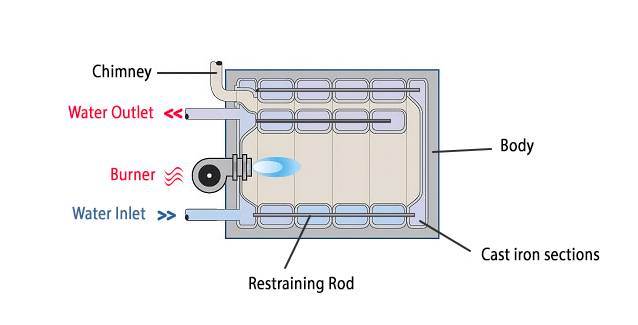

The working mechanism of cast iron boilers is based on the burner flame being positioned in the space between the sections. The generated heat passes through these passages and is then transferred to the water. Thanks to their sectional design, cast iron boilers are easy to transport and install, even in underground boiler rooms or locations with difficult access.

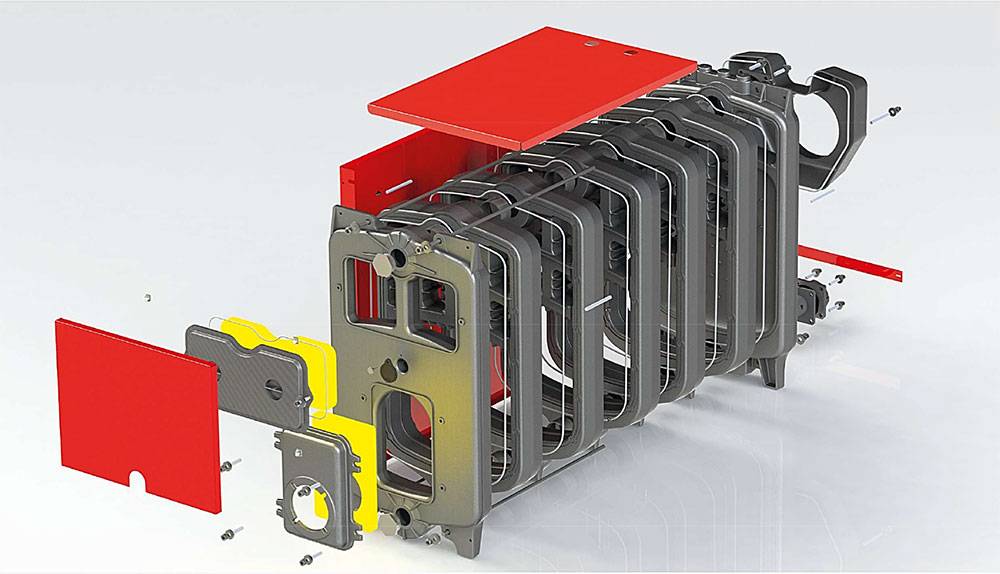

Cast iron boilers are composed of several middle sections along with a front and a rear section, all connected to each other using nipples. The middle sections are placed between the front and rear ones. Here, you review the most important considerations when selecting and purchasing a cast iron boiler. With the technical data and the price list provided by DamaTajhiz HVAC Co., you can make the most efficient and reliable choice for your project.

5 Factors to Consider When Selecting Cast Iron Boilers

When selecting a cast iron boiler, you should consider the following 5 parameters:

- First, obtain the amount of heating power required by the building based on the useful area of the floors and the geographical location of the boiler, according to the method presented below.

- Obtain the amount of heating capacity for supplying hot water for consumption (and other uses such as swimming pools and spas) according to the method below.

- By adding the numbers obtained from your calculations from rows 1 and 2 and adding a 20% safety factor to their total, the capacity of the hot water boiler for the engine room of your building is obtained.

- Using the technical specification tables provided in the various cast iron boiler products, select your cast iron boiler in the appropriate capacity.

- Pay attention to the dimensions of the cast iron boiler you choose for installation in the engine room.

Note: The selected cast iron boiler should have at least 7 fins (due to the burner flame's thermal stress in the boiler's end fin).

- It is also strongly recommended to avoid purchasing and using non-standard, workshop-made steel hot water boilers because of their very short lifespan, the frequent occurrence of leakage or perforation within only 3 to 4 years, and their low thermal efficiency.

Cast Iron Boiler Heating Capacity Calculation

To calculate the approximate heating power of the cast iron boiler, multiply the infrastructure of the building by 100 (kilocalories), and then, for each residential unit, add an extra 6000 (kilocalories) for their water consumption in weather conditions such as:

- Saudi Arabia: Yanbu, Jeddah, Mecca, Al Wajh, Al Hufuf, Unayzah, Buraydah

- Lebanon: Baslouqit, Bdebba, Baddouaa, Abu Saad, Aassoun, Deir Janine, Halba, Hakour, Haizouq

- Yemen: Ayn Milh, Tarim, Ard al Huwayl, Ard as Suqayr, Bayt al Mudir, Al Ma'shur

- Iraq: Amarah, Nasiriya, Kut, Kerbela, Semawa, Badrah, Rafaei

- United Arab Emirates—UAE: Dubai, Difan, Bida, Ghayl, Uwaynat, Ar Rafa'ah, Lazimah, Adh Dhayd, Layyah

- Qatar: Duha, Al Rayyan, Al Daayen, Al Wakrah

- Kuwait: Jahra, Sulaibiya, Al Wafra, Abdaly, Sabriyah

- Syria: Deir ez-Zor, Al Raqqah, Al Hasakah, Hama, Daraa, Aleppo, Homs, Idlib

- Turkey: Cizre, Urfa, Batman, Siirt, Izmir, Adana, Amasya, Istanbul

- Azerbaijan: Saatly, Sabirabad, Zerdab, Imishli, Beilagan

- Armenia: Armavil, Aragatsotn, Yerevan, Syunik, Tavush, Ararat, Kotayk, Lori

For example, for a building with a useful infrastructure of 2500 square meters and 18 apartment units, the required heating power of the cast iron boiler is 358,000 kilocalories = (18 × 6000) + (100 x 2500). Usually, after this calculation, up to 20% as a safety factor is added to the calculated capacity.

Approximate capacity of cast iron boiler (kcal/hr) = (100 kilocalories * useful infrastructure area of the building) + (6000 kilocalories * number of residential units) + (necessary heating for swimming pool).

To calculate the capacity of the cast iron boiler or other types of hot water boilers required based on the number of units, the size, and type of building, the presence or absence of a hot water pool, etc., you can consult the experts of DamaTajhiz HVAC.

Cast Iron Boiler Heating Capacity Required for Pools & Hot Tubs

To approximately calculate the required heating power for a pool and/or hot tub and add it to the heat capacity of a boiler (cast iron or steel), use the following formula:

In the above formula, the pool water volume is in (liters), and the temperature difference is in (Celsius). Usually, the temperature difference between the water entering the pools is about 20 °C. The temperature difference between the water entering the hot tub is about 30 °C (due to the 10-12 °C of the water in the pipes), and these numbers should be included in the above formula as "ΔT".

However, the swimming pool water heating time is not subject to specific rules and is included in the above formula, according to the type of pool usage. On average, the heating time in private pools is between 18 and 24 hours, in public pools between 48 and 72 hours, and in hot tubs between 4 and 8 hours.

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

Notes:

- The amount of heating obtained from the above formula is suitable for indoor swimming pools and hot tubs. And for outdoor pools, this number should be doubled.

- In general, the numbers obtained from the formula above are estimates. So it is recommended to add nearly 10% to the obtained capacity when selecting a boiler (either cast iron or steel boilers).

Cast Iron Boiler Advantages and Features

Here are some of the cast iron benefits and features, yet not all of them:

- Easy transportation of cast iron (finned) heating boilers due to the ability to separate the sections from each other.

- Resistant to rust and wear.

- The price of cast iron boilers is more reasonable than that of steel boilers in the same capacity and working pressure.

- Increasing or decreasing the heating capacity of the boiler by increasing or decreasing the number of sections of the cast iron heating boiler in the engine room.

- The ability to repair and replace sections and replace them with new sections if any of the blades of the cast iron boiler are punctured.

One of the main reasons behind the popularity of cast iron boilers is the ease of transportation and installation. These boilers consist of separate sections, each of which can be carried and installed individually. This feature becomes particularly useful in buildings where the boiler room is located on basement levels or in areas with limited access.

Furthermore, it is strongly recommended to avoid selecting, purchasing, and using non-standard, workshop-made steel hot water boilers (especially in small capacities), due to their very short lifespan, the frequent occurrence of leakage within only 3 to 4 years, and their low thermal efficiency.

Essential Equipment for a Simple Engine Room

Here are the 14 most essential pieces of equipment every simple engine room should have:

- A central boiler (either cast iron or steel)

- A submerged Augusta smart programmable thermostat for the boiler

- A Manometer thermometer for the boiler

- A Burner for boiler (desired fuel type)

- A gas hose and filter with the right size (or diesel nozzle and filter for diesel burners)

- A Hot Water Tank (coiled or double-wall tank)

- A temperature and pressure valve

- A linear circulator pump (usually 2 inches HV, 2 inches AA, 2 inches A6 or 2 inches A7, etc., based on the infrastructure size)

- A septal Augusta (to operate the circulator pump command)

- A water return pump (usually a linear pump)

- A one-inch hot water return flange

- An expansion tank (either galvanized or aluminum)

- An expansion tank float valve (metal or plastic)

- An engine room electrical panel with at least 5 cells

Tips for Installing and Using a Cast Iron Boiler

Here are the most important factors and tips that you should keep in mind when choosing and installing a cast iron boiler:

The Possibility of Defects and/or Failures

Considering the importance of the boiler and burner as the heart of the central heating system of any building, and the need to consider the possibility of defects and failures in their operation (in the long term), as well as the possibility of saving as much fuel as possible.

So if the number of residential units in the building is 8 or more, or the total area of the useful substructure of the building is more than 1000 square meters, it is recommended to install two cast iron boilers (according to the installation standards), so each one can provide 60% of the heating capacity required for the entire building.

Cast Iron Boilers for Public Service Buildings

In public service buildings such as hospitals, hotels, etc., regardless of the type of boiler selected (cast iron or steel boiler), for the central heating system, according to the recommendation of international engineering standards, 3 boilers are required, each with the power to provide 75% of the building's heating power needs.

So that even if one of the burners or boilers is damaged or causes problems, the other boilers can provide a significant portion of the work.

The Location of the Engine Room

Considering the importance of the building's engine room as a power center for providing cooling and heating, it is recommended that the location of the engine room be considered.

In such a way that, in addition to the possibility of easy movement and a large entrance door to carry required equipment, it should have a large area, as well as sufficient light and proper ventilation.

Additionally, considering that the installation of all the main engine room equipment, including the central boiler, is completed on a pre-made concrete foundation with suitable dimensions according to the placement plan, and exactly where the equipment is located. Therefore, before installing the main engine room equipment, including the cast iron boiler.

Cast Iron Boiler Cover

After installing and sealing the cast iron boiler in the engine room, installing the boiler cover prevents heat loss and overheating (due to the layers of glass wool or stone wool inside the boiler cover), in addition to finishing and beautifying it.

Thermostat & Thermometer

Installing a manometer thermometer to display the temperature of the hot water and the pressure of the device is mandatory on every hot water boiler.

It is also necessary to install a submerged programmable thermostat (Augusta smart thermometer) with a temperature range of 30°C to 90°C (or 30 °F to 110°F) to adjust the boiler temperature as well as the ON/OFF command to the burner relay on every cast iron boiler.

So, when ordering a cast iron boiler, you can pick the Augusta smart thermometer (IMIT, Honeywell, or other brands), as well as a thermometer and manometer (Fimet or any other brand) from the sales experts of DamaTajhiz HVAC.

Note: Cast iron hot water boilers are commonly used in the engine room of apartments and houses that, firstly, have a smaller engine room, and secondly, it is not possible to easily pass a large, integrated steel boiler in them.

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

The Main Components of the Cast Iron Boiler

Cast iron boilers are made up of different components, each of which has its particular tasks in the operation. The components of a cast iron pot are as follows:

- Cast Iron Fins: The cast iron sections consist of a front section, middle sections, and a rear section, depending on the model of the cast iron boiler such as Super, Solar, Turbo, M, L, and others. After these sections are connected to one another using nipples and boiler sealant, the closed-loop heating water of the building circulates inside them. Once heated by the burner flame, the water flows from the boiler toward the radiators, fan coil units, coil tanks, and double-wall heat exchangers.

- Inlet and Outlet Water Flanges: The inlet and outlet water pipes of the boiler are connected to the flanges.

- Flame Inspection Valve: This valve is installed on the casing of the boiler to observe the burner flame and combustion performance.

- Four Restraining Rods: Restraining rods are used to keep the cast iron blades of the boiler stable relative to each other.

- The Chimney Connection: It is responsible for removing the gases from combustion.

- Boiler Cover and Insulation: Boiler cover and insulation (body sheets) are installed to prevent heat loss and the beauty of the boiler.

- Burner: Based on the type of fuel — gas, diesel oil, heavy fuel oil (mazut), dual-fuel, or tri-fuel — the burner is responsible for combustion and generating the required thermal energy in the cast iron hot water boiler used for central heating.

Key Factors that Can Increase the Lifespan of a Cast Iron Boiler

These 8 rules of thumb will help you increase the life of your cast iron and let you benefit from its performance for years to come:

- Choosing the appropriate capacity of the boiler so that even on the coldest days of the year, the boiler does not have to work continuously and without interruption.

- Choosing the right burner (maximum 20% more than the boiler capacity).

- Use a proper resin water softener based on the water volume, as well as a scale remover on the engine room pipes in a sufficient number and size.

- Adjust the burner flame (blue flame and direct longitudinal to the boiler).

- If a diesel burner is used, the type and angle of diesel injection from the burner nozzle are determined based on the diameter and length of the combustion chamber of the boiler and, according to the suggestion of the boiler manufacturer.

- The appropriate length of the combustion chamber of the boiler and the non-permanent impact of the flame on the rear or middle fins of the boiler.

- The continuous thickness in all parts of the cast iron boiler body.

- Proper sealing of the fins during installation, leakage check, and controlled pressure of the water circulation inside the boiler.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

Buying Cast Iron Boilers

According to their capacity, cast iron boilers consist of many middle fins, the front fin, and the rear fin, which are connected by bushings. The front and rear fins are different, while all the middle fins are the same.

To find the best cast-iron boiler that suits your needs, you must first determine the capacity, dimensions, and working pressure of the device. In DamaTajhiz HVAC Co. centre, the technical information of dozens of cast iron boilers from reputed brands, with their main guarantee, is provided for optimal and smart shopping.

Advantages of Buying a Cast Iron Heating Boiler from DamaTajhiz HVAC

Here are the benefits of buying a cast iron heating boiler from the DamaTajhiz HVAC store:

- High Quality and Product Authenticity: By purchasing a cast iron boiler from the DamaTajhiz HVAC store, you will be sure that you are receiving an original and quality product from popular brands.

- Wide Selection of Brands and Models: DamaTajhiz HVAC store offers various types of cast iron boilers in different capacities and working pressures. This includes well-known brands such as Shufazhkar, Mi3, etc., which allows you to choose the best cast iron boiler suitable for the desired project based on your needs and budget.

- Reasonable Price: DamaTajhiz HVAC store offers cast iron boilers at reasonable and competitive prices.

- Consulting and Technical Support Services: DamaTajhiz HVAC store also provides technical consulting services to its customers. This helps you choose a suitable cast iron heating boiler based on the needs and technical specifications of your building space. Technical support and consulting services will also be available to you after purchase.

- Fast Delivery: DamaTajhiz HVAC store provides customers with the opportunity to enjoy heating their space without delay by quickly delivering cast iron boilers.

- Online Shopping: You can easily and in the shortest possible time browse, compare, and order your desired cast iron boiler through the DamaTajhiz HVAC store. This process is easy and simple and allows you to make your purchase at any time of the day or night, in addition to the possibility to order by phone.

Considering these benefits, purchasing a cast iron boiler from the DamaTajhiz HVAC store is an excellent option for people who are looking for authenticity, choosing the right capacity, reasonable prices, and reliable services.

DamaTajhiz HVAC, with a history of 11 years of great service since 2004, has become the best reference for purchasing this type of equipment in the Middle East.

The Price of Cast Iron Boilers

Considering these benefits, purchasing a cast iron boiler from the DamaTajhiz HVAC store is an excellent option for anyone seeking authenticity, choosing the right capacity, reasonable prices, and reliable services.

DamaTajhiz HVAC, with a history of 11 years of great service since 2004, has become the best reference for purchasing this type of equipment in the Middle East.

The Most Cost-Effective and Updated Cast Iron Boiler Price List

In the following table, you will find a selection of the best-selling and latest cast iron boilers from the well-known brands Shoofazhkar and MI3, along with their technical specifications and current market prices.

Reviewing the technical specifications and the Cast Iron Boiler Price List will help you select the most economical option from reputable and high-demand brands in the shortest possible time and purchase it with greater confidence. Before buying a cast iron boiler, we recommend that you contact the specialists at DamaTajhiz to access competitive prices, complete technical data, and free professional consultation. This way, you can make a safe and well-informed decision.

| Cast Iron Boiler Brand | Cast Iron Boiler Model | Capacity (kcal/hr) |

Cast Iron Boiler Price (USD) |

|---|---|---|---|

| Shoofazkar | Super400 | 369700-118700 | From 593 to 1350 |

| Shoofazkar | Turbo | 590000-243000 | From 1057 to 1901 |

| Shoofazkar | Solar300 | 89000-43000 | From 300 to 523 |

| MI3 | Model M | 300000-100000 | From 626to 1524 |

| MI3 | Model L90 | 560000-172000 | From 1233to 2371 |

| MI3 | SUPER M90 | 326800-90300 | From 513 to 1379 |

| MI3 | SUPER L90 | 578000-302720 | From 1189 to 1794 |

Note: For the most competitive and up-to-date offers, technical details and free consultation, please contact the DamaTajhiz specialists.

Dear Users, If you still have any unanswered questions about cast iron boilers you can contact the DamaTajhiz HVAC sales team at extension numbers 107 - 108 - 121 - 122.

DamaTajhiz HVAC Group provides all kinds of cast iron boilers in the Middle East region. If you need a cast iron boiler for any of the countries in the region, you can place your order with our sales team.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.