Chiller

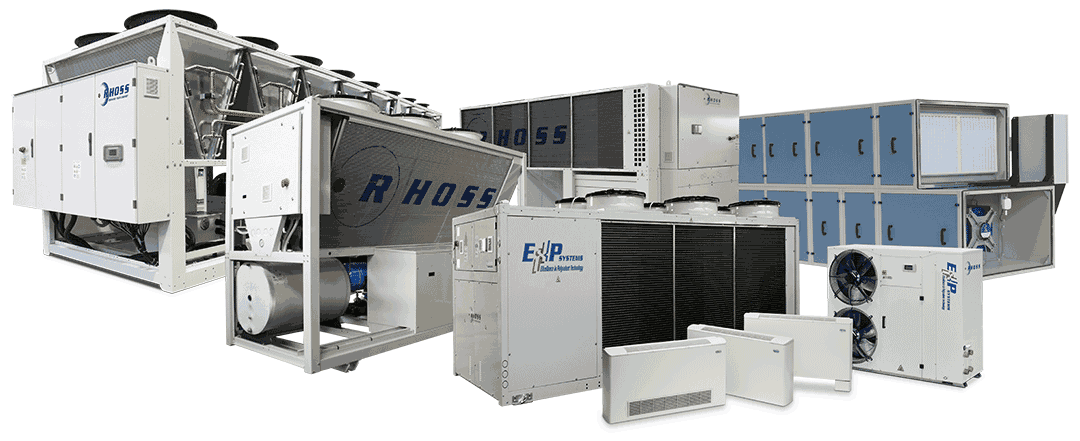

A chiller is the most important component of any central air conditioning system, often referred to as the heart of the system. There are 2 main types of chillers; compression and absorption. These come in different shapes, sizes, capacities, and brands.

Chiller Expert Selecting Guide and Price List

A chiller is a machine that removes heat from a liquid by lowering the temperature of the water before circulating through cooling devices such as fan coils and air conditioning units, thus cooling the air.

Review, Selection, and Pricing of HVAC Equipment

What is a Chiller?

In general, chillers are the central core or beating heart of any system that performs its environmental function by reducing the temperature of the system water and circulating it in the , air conditioners, and other cooling equipment. Chillers have different types in terms of performance, which are produced in industrial and domestic markets and have different capabilities.

These equipments have different types (compression and absorption chillers), designs, brands, accessories, etc. Due to their high quality and capabilities in producing cool and comfortable air, chillers are generally more expensive and are considered capital goods in any building. Therefore, it is necessary to buy them with sufficient knowledge.

Types of Chiller in Terms of Operation

Chillers are divided into two main groups in terms of how they operate: compression chillers and absorption chillers. Compression chillers operate in such a way that they require high-power electrical energy to start working; while the main energy required to start absorption chillers is natural gas, directly or indirectly (hot water absorption chillers).

Compression chillers are also divided into two types, air-cooled and water-cooled, based on the type of condenser they have. To learn more about the types of chillers and better understand their classification, please continue reading:

Compression Chiller (Vapor Compression)

As mentioned, compression chillers are divided into two groups based on the type of condenser: water-cooled (water) compression chillers and air-cooled (air) compression chillers.

The working cycle of air-cooled and water-cooled compression chillers is similar and based on the refrigeration compression cycle, and they require strong primary electrical energy to produce cold.

In water-cooled chillers, the heat taken from the interior of the building is transferred to the outside environment through a shell-and-tube condenser and in proximity to the water in the cooling tower. In air-cooled compression chillers, the heat taken from the interior of the building is transferred to the outside environment through a ventilation fan installed inside the condenser in the open air of the roof or balcony of the building.

Water-cooled chillers have the advantage of being less expensive compared to air-cooled chillers. On the other hand, air-cooled chillers offer the ability to operate in humid weather conditions, the option for installation on roofs, balconies, or any outdoor space, and no requirement for a cooling tower or water consumption.

The types of compressors used in vapor compression chillers are:

- Reciprocating compressors (piston)

- Screw compressors

- Scroll compressors

- Centrifugal compressors (New-generation)

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

Scroll compressors have a wide range of capacities; therefore, a variety of these compressors can be used to manufacture compression chillers with a capacity of 20 tons to 200 tons of refrigeration, but screw compressors are usually used to manufacture compression chillers with higher capacities (from 100 tons to 500 tons of refrigeration).

Piston and centrifugal compressors are also used to manufacture compression chillers with very high capacities, mostly for industrial and special applications.

Note: Rotary compressors are also mainly used in the manufacture of mini chillers with low capacities (less than 20 tons of refrigeration).

Absorption Chiller (Vapor Absorption)

Absorption chillers, which require a heat energy source, are categorized into five types:

- Warm water absorption chillers

- Hot water absorption chillers

- Direct flame absorption chillers

- Steam absorption chillers

- Energy recovery absorption chillers

Vapor absorption chillers are also divided into two groups based on internal operation: single effect and double effect.

The new generation of absorption chillers, which have a higher coefficient of performance and are among the best-selling chillers, are direct flame double-effect absorption chillers that can easily cool water to 7 degrees Celsius.

The main equipment of absorption chillers includes lithium bromide, a generator, an evaporator, a refrigerant pump, an absorber, a solution pump, distilled water, control valves, an electrical panel, and its control circuit.

Compression Vs. Absorption Chillers

In a general comparison between compression and absorption chillers, it can be noted that absorption chillers require the main gas energy to start working and cool the ambient air, and their electricity consumption is very low. Therefore, there is no need to provide a strong power supply and high electricity bill in this regard. Compression chillers, on the other hand, require a strong power supply to start working and be productive.

Compression chillers have a much higher coefficient of performance and efficiency than absorption chillers.

Also, the internal cycle of compression chillers is based on the refrigeration compression cycle; while the internal cycle of absorption chillers is based on operation in vacuum conditions, heat absorption, water evaporation, water absorption by lithium bromide, and then the operation of separating water from lithium in the generator (in the vicinity of combustion or hot water).

Types of Chiller in Terms of Usage

In terms of usage, chillers are divided into two categories, home or apartment chillers and industrial chillers:

Home or Apartment Chiller

A home or apartment chiller is one of the best air conditioning systems with the ability to produce very cool and comfortable air and is suitable for use in not only homes but also villas, offices, etc. The function of these chillers is to produce cool water and then pump it to fan coils installed in the hall and rooms and re-circulate cool water. These chillers are divided into two types air-cooled and water-cooled in terms of performance and internal structure.

If you are looking for the best option for providing cooling for your residential home or villa, home chillers are the safest and best option. However, due to their very high ability and quality in creating cold, these devices have a higher initial price than other options.

Note: For areas less than 500 square meters, air-cooled mini chillers are usually used in the appropriate capacity.

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

Industrial Chiller

In general, chillers (air-cooled chillers, water-cooled chillers, and absorption chillers) as one of the air conditioning systems, in addition to the ability to provide cool and air-conditioned air in residential homes, offices, service centers, commercial centers, etc., are also widely used in various industries such as glass factories, food industries, pharmaceutical and chemical industries, steel industries, petrochemical industries, wood and paper industries, paint and adhesive production industries, etc.

Thus, industrial chillers are used in industrial factories for the product production process and the need to cool it during the production stages, as well as due to the continuous operation of large industrial machines in these factories to prevent their temperature from increasing.

These chillers have large capacities and the ability to produce cold water, its circulation in heat exchangers prevents the temperature from increasing in industrial equipment.

Chiller Components

Given that chillers are divided into two groups: compression and absorption chillers, each has different components:

Absorption Chiller components

The most important components of absorption chillers include lithium bromide, distilled water, evaporator, absorber, generator, condenser, electrical panel and its control system, refrigerant pump, solution pump, and solenoid and manual valves.

Compression Chiller components

In general, the operation of compression chillers (air-cooled and water-cooled) is based on the compression refrigeration cycle, and their internal components include a compressor, condenser, evaporator, electrical panel and its control system, expansion valve, and solenoid and manual valves.

In comparing the types of compression chillers, the only major difference between water-cooled and air-cooled compression chillers is their condenser type; In this way, water-cooled compression chillers are equipped with a shell-and-tube condenser and transfer the heat taken from the interior of the building to the outside environment through proximity to the water of the cooling tower. This is done in air-cooled compression chillers through the air and a condenser equipped with an air fan.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

Advantages and Features of Chillers

Each type of chiller has specific advantages depending on the facilities and conditions specific to your project. Therefore, considering the general classification of chillers, it can be noted that absorption chillers have very low electricity consumption without the need for the cost of purchasing any strong electrical component, and the main initial energy for starting them is mainly natural gas.

On the other hand, in the comparison between absorption and compression chillers, it can be said that the coefficient of performance of compression chillers is much higher than absorption chillers.

In other words, compression chillers have better efficiency and cooling power. In the classification of water-cooled and air-cooled compression chillers, each has specific features and advantages over the other.

Chiller Ultimate Buyers Guide

Today, achieving the desired temperature in various environments (homes, offices, etc.) requires advanced equipment to provide cooling during hot seasons. Chillers are among these essential and advanced devices.

On the specialized website of the DamaTajhiz HVAC group, comprehensive information about the various types of chillers is available for you, our valued visitors. This information will assist you in making the best decision when purchasing a chiller.

Approximate Calculation of a Chiller Capacity

To determine the chiller capacity needed for a project is crucial to consider both the nominal and actual capacity of the chiller, particularly concerning the average temperature (outdoor) of the hottest days of summer in the chiller’s operational area.

Typically, facility experts calculate the capacity of a chiller for each project by considering factors such as:

- Geographical conditions (ambient temperature)

- The average temperature of the hottest days of summer (outdoor temperature)

- Altitude above sea level

- Relative air humidity

- Building usage (average indoor temperature)

- Building materials and design

- Building orientation with the sun

- Number of floors and building surface area

- The number of occupants and electrical equipment inside the building

These factors help determine the volume of cold water needed and the appropriate reliability coefficients for the chiller's performance.

For an initial estimate (phase 1 electricity) of the required chiller capacity for residential and office buildings in climates similar to Tehran, Mashhad, Karaj, Isfahan, Erbil, Kabul, Sulaymaniyah, Halba, and other cities with comparable conditions, you can consider a nominal capacity of 1 ton of refrigeration (12000 BTU) per 30 square meters of the building.

Before finalizing the capacity calculation and selecting the required chiller for your project, consult with the experts at DamaTajhiz HVAC Group for accurate cooling load calculations. Our team is always available to assist you.

Buying a Chiller

On the DamaTajhiz HVAC website, you can find technical information for either water or air cooled chillers in various reputed brands with their main guarantee (currently only available in Iran) as we aim to provide the best options for optimal and smart purchases.

Chiller Price

There are various effective factors that affect the price of a chiller. The most important of which are the type of the chiller (air-cooler or water-cooled – vapor compression or vapor absorption), capacity and other technical specifications, manufacturing quality, and the brand of the chiller.

Additionally, the cost of the device installation varies depending on capacity, specific project conditions, and workers' fees.

All chillers featured on the DamaTajhiz HVAC website have product identification ID and competitive prices, with discounts already included.

Things You Need to Know Before Buying a Chiller

Ordering products online is one of the new methods for purchasing and purchasing various types of equipment, including chillers, which allows customers to easily and at any time select and order the chiller they need.

However, for a successful shopping experience, there are some tips and recommendations that should be considered. The following are some of these important points in selecting and ordering chillers online:

- Adequate research: One of the first tips for selecting and ordering chillers and other equipment online is sufficient and detailed research on models, brands, and various features of chillers. By studying the technical specifications, dimensions, capacity, etc., you can choose a suitable and high-quality chiller.

- Choosing a reputable brand and product authenticity: Choosing well-known and authentic brands that have good quality and performance will give you more confidence in your purchase.

- Reviewing customer feedback: Reading feedback and opinions from other buyers can help you make a better choice.

- Price comparison: Before placing an order, comparing prices, finding discounts, offers, and competitive prices are important, and considering these, you can buy the chiller you need at a more affordable price.

- Terms and conditions of purchase: Before placing an order, be sure to read the terms and conditions of purchase carefully. This includes warranty conditions, shipping and delivery costs, installation costs, etc. It is especially important to read the sections related to the warranty.

- Ordering and receiving delivery information: After completing the above steps, it is very important to order and receive information about the delivery of the chiller. Be sure to enter your contact number and address correctly and accurately so that the chiller reaches you without any problems.

- Tracking and notification: After placing an order, it is also important to track and receive information about the status of your order, which can be done via SMS, email, user panel, etc.

- Delivery and installation: After receiving the chiller, first check it and ensure its health and performance. Also, if installation is required, contact the relevant specialists and be sure to entrust the delivery and installation to the after-sales service of the same brand.

By following these tips and recommendations, choosing and ordering a chiller online can become an interesting and successful shopping experience.

Remember that careful research and examination, selection of a reputable brand, and complete information about the terms and conditions of purchase are the most important factors for success in online purchasing of chillers and other equipment, fortunately, the specialized DamaTajhiz collection has solved all the challenges, including the ones mentioned above.

Can a Chiller be Used for Heating Proposes?

In general, the main capability and function of a chiller is to produce cold, but according to the type of buyer's needs, it is possible to add heating capability to the chiller by installing external heating components such as a heat pump, such as a special four-way valve and changing the refrigerant flow path (in fact, by shifting the role of the evaporator and condenser relative to each other).

However, due to the high costs of electricity consumption of the chiller and on the other hand, to prevent premature depreciation of the internal parts of the device and the possibility of damaging them, using absorption and compression chillers for heating in winter is not cost-effective and is not recommended.

Then again, before purchasing the desired chiller, consider its capacity, dimensions, transportation method, and installation feasibility in the engine room.

It is also crucial to consider adequate lateral and longitudinal spacing for annual maintenance of the condenser, evaporator, and chiller compressor and any potential repairs. Adhering to these intervals is the key to ensuring routine maintenance and keeping chillers operating at optimal performance levels.

Dear users:

Reading the stated information above in order to obtain additional information to purchase the types of chillers. You can also contact the experts of the AC equipment by dialing one of the extension numbers 117-119-120-126-317 in order to get advice or just to ask your questions.

Dear users, while thanking you for the trust you put in the technical opinions of air conditioning sales experts of DamaTajhiz to buy DamaTajhiz mini chillers, it should be noted that the choice of the desired product brand based on history, brand strength, service and product price is ultimately determined by the buyer.

Also, taking into account that the Damatajhiz HVAC Group is one a member of the main group specializing in heating equipment, is the first and the most viewed authority for selling air conditioning equipment, as well as an official member of the heating and air conditioning equipment sellers' union. Therefore it is now safe to say that we provide all kinds of chillers in the Middle East region. Therefore, if you are from the same country in the region and you need a cooling tower, please place your order with our sales experts team. Product warranty and a reasonable price are included.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet With You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.