Air Handling Unit (AHU)

Air Handling Unit (air handler) controls temperature and humidity in rooms, halls, theaters, hospitals, etc. Below are the selection guide, technical specifications, and the best prices for types of AHUs.

Air Handling Unit Expert Selecting Guide and Price List

Air handling unit (AHU) is one of the most important types of equipment for providing comfortable and fresh air with the ability to control temperature and humidity in cold and hot seasons. The air handling unit is one of the main equipment of air conditioning systems that can be installed and operated in all climates of Iran.

Air handling units usually include a few components: an air-sealed body, fan, electric motor, air filters, cooling and/or heating coils, humidifier sprayers, inlet and outlet air dampers, and return air and control equipment. Furthermore, if you are thinking about purifying the air in your home or office, you can see a wide list of those devices in the air purifier section. Keep reading to learn more about AHU types and brands.

Review, Selection, and Pricing of HVAC Equipment

How Air Handling Units Work in HVAC Systems

The air handling unit is not a cooling device, and for this reason, it cannot be used alone to create cooling or heating; in other words, the air handling unit requires the use of other air conditioning equipment such as a chiller (for cooling) and a hot water boiler or combi boiler (for heating) to cool or heat the environment.

The operation of the air handling unit in HVAC systems includes regulating the temperature, humidity, speed, and direction of the clean air distributed to the building, and the process is carried out as follows:

In the first stage, cold water from the chiller or hot water from the hot water boiler is pumped through the coils or copper pipes of the air handling unit.

Then, fresh air and return air from the building's air ducts mix inside the air handling unit and pass through the primary aluminum filter to create clean air and prevent the accumulation of suspended particles and pollutants on the heat exchange pipes and fins.

Thus, in summer, the air is cooled by passing through the fins of the cold water (or refrigerant) coil from the chiller, and in winter, it is heated by passing through the fins of the hot water (or steam) coil from the boiler.

This air is then directed by the supply fan to the ducts installed in various spaces of the building. Additionally, the process of humidifying the air is carried out using water or steam inside the air handling unit before it is distributed in the ducts.

Air Handling Unit Applications

In addition to ventilation and providing air with the right temperature, air handling units can transfer clean air with the humidity the user requires to the environment.

In general, it is common to use an air handling unit for spaces that have a large and integrated area or require a significant volume of fresh air in terms of temperature and humidity, including:

- Gyms

- Hotels and entertainment centers

- Universities and educational centers

- Hospitals and medical centers

- Restaurants and reception halls

- Industrial workshops and factories

- Seminar halls and gatherings

Another important point for the users of all types of air handling units is that these devices are used as central devices and, therefore, cannot be used for separated spaces that require independent and different temperature control (such as residential units, office units, or shops in a commercial center).

As we have already mentioned, air handling units are considered a type of air distributor that alone cannot provide cold or hot air, and heat energy must flow through the building's central heating engine system to provide hot air. Naturally, in the case of cooling, cold water of 7 to 12 degrees Celsius must first be transferred from the building's chiller to provide cool air with an output temperature of 16 to 18 degrees Celsius.

Advantages of Air Handling Units

An Air Handling Unit (AHU) is considered one of the most comprehensive HVAC systems, capable of providing cooling, heating, air filtration, and even humidity control.

The main advantages of air handling systems include:

- The ability to supply and distribute large volumes of fresh air to different areas of a building through ductwork.

- Another key feature of an AHU is the continuous intake of fresh outdoor air and its replacement with indoor air, which improves air quality, increases oxygen levels, and reduces environmental pollutants.

- In full fresh air handling units, 100% of the air passing through the system is supplied from outside air with no recirculation of indoor air. This feature is particularly critical in sensitive environments such as operating rooms, high-tech halls, and similar spaces.

- Simultaneous control of temperature and humidity is another important advantage of AHUs. By installing humidifiers, dehumidifiers, and appropriate control systems, environmental conditions can be regulated with high precision. Even without these components, cooling coils naturally reduce a portion of the air humidity during warm seasons.

- Air handling units also perform very well in air purification. The use of various filters removes dust, airborne particles, and contaminants, making AHUs one of the best solutions for air purification in industrial, healthcare, and commercial projects.

Disadvantages of Air Handling Units

Despite the significant advantages of air handling units, they also have certain limitations, as outlined below:

- The most important limitation of an AHU system is the lack of independent temperature control for separate spaces. The unit supplies air at a uniform temperature and distributes it throughout the building via ducts, making it impossible to adjust the temperature individually for each room or occupant. Therefore, using an AHU alone is not suitable for residential or office buildings that require independent temperature control in each space. In such cases, fan coil systems are typically a better option, as each space’s temperature is controlled separately by a thermostat. To overcome this limitation, many projects use a combination of air handling units and fan coils. In this configuration, the chiller and boiler are connected to both systems, allowing the AHU to provide fresh air and air purification—especially in lobbies, conference halls, and other public areas—while fan coils ensure independent temperature control in private spaces.

- Another disadvantage of air handling units is the requirement for substantial installation space and duct routing. AHUs are typically installed in mechanical rooms, rooftops, or service areas, and the air ducts occupy considerable space. As a result, this can pose challenges in buildings with limited ceiling height or compact architectural layouts.

- Finally, the performance of an air handling unit heavily depends on proper engineering design. If the AHU capacity or the dimensions of ducts and air distribution outlets are not accurately calculated and executed, it can lead to poor air distribution, increased noise levels, pressure losses, higher energy consumption, and ultimately dissatisfaction of the owner or occupants.

Types of Air Handling Units In Terms of Fan Location

Based on the type of arrangement or location of the fan, AHUs are divided into two categories: "Draw-Through" and "Blow-Through":

Air Handling Units with Draw-Through Fans

In this system, the fan of the unit is placed after the cooling coil and sucks the air between the coils and the mixing box and distributes it into the channels.

Air Handling Units with Blow-Through Fans

In this system, the fan of the unit is placed before the cooling coil and blows air through the coils to the air distribution channels.

Types of Air Handling Units in Terms of Airflow Control

The air handling units' airflow is controlled by two methods: fixed-speed and variable-speed of the engine and the ventilation fan. Therefore, in terms of the type of airflow control, air handling units are divided into two categories: "Constant Air Volume" and "Variable Air Volume".

Constant Airflow Ventilator (CAV)

In constant volume (CAV) air handlers (abbreviation for Constant Air Volume), as their name suggests, the volume of air coming out of the device is always constant, but the temperature of the cold water coils of the chiller and the hot water or steam boiler coils varies.

This means that the fan of this type of air handler (which is of the fixed round type) continuously blows a fixed amount of air over the coils, and with the change of the temperature inside the building, and based on the detection and command of the room thermostat, to the solenoid valve. A three-way motor is installed in the cold and hot water path to the cooling or heating coils, and the temperature of the coils changes accordingly.

Variable Air Flow Ventilator (VAV)

The performance of variable volume (VAV) air handling units is almost the opposite of fixed volume air handling units. In this way, the volume of the air coming out of the device varies, but the temperature of the cold and hot water flowing in the cooling and heating coils is constant.

As a result, when the amount of air passing over the coils is changed by the VAV fan, the volume of cold or warm air entering the building is also reduced or increased based on the temperature requirements. The energy consumption of VAV air handling units is lower due to the use of an inverter fan.

Types of Air Handling Units in Terms of Airflow Direction

In terms of the direction of the airflow, the air handler system includes three types: forward airflow, upward airflow, and downward airflow, in each of these devices, the air is blown forward, upward, and downward, which is based on the physical conditions and project location of the device.

Types of Air Handling Units in Terms of Aeration Zone

Based on the zone or the number of air outlets, air handling units include single-zone and multi-zone types.

Single-Zone Air Handling Unit

A single-zone air handler has only one air outlet with the same temperature and humidity conditions; Therefore, single-zone air handlers blow air to different parts of a building that are connected by ducts uniformly with constant conditions, certain temperature, humidity, and flow rate.

Multi-Zone Air Handling Unit

A multi-zone air handler has more than one air outlet and is able to produce an airflow with different conditions (temperature, humidity, etc.). Therefore, when it is necessary to control the temperature or other control indicators of each of the different parts of the building independently and separately from other parts, this type of air handler is used.

Note: It should be noted that in multi-zone AHU, a separate channel needs to be connected to the device for each section of the building.

Types of Air Handling Units in Terms of Aeration Cycle

Based on the aeration cycle type, air handling units are divided into two groups: "Full Fresh AHU" and "Return AHU", which must be selected and prepared based on the needs of the project and engineering calculations.

Regular return-type air handlers generally have three airflow valves, each of which has the following functions:

- Fresh air inlet from the outside into the air handler

- The air exit valve from the device into the building

- Return duct and valve that returns some of the air back to the device

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

Types of Air Handling Units in Terms of Usage

Air handling units are designed and produced in different types based on several factors, which include:

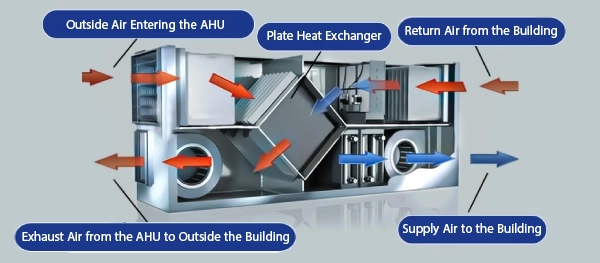

1. Heat Recovery Air Handling Units

In a brief explanation, it can be said that the heat recovery air handler or energy recovery is an air handler that consists of two passing air streams, and using a heat exchanger (of the air-to-air type), heat is extracted from the return airflow. Transfers to fresh air flow. To learn more about the structure, operation, and benefits of the heat recovery air handling unit, refer to the article on the heat recovery air handler and its use.

2. Home Air Handling Units (Domestic AHU)

Home air handling units differ greatly from industrial air handling units regarding their internal structure. The working principle of these air handling units is to provide comfortable air with the desired temperature and humidity, which also filters the air and captures the dust to provide clean air.

The performance of a home air handling unit is nothing different from an industrial one, which circulates the air through cooling and heating coils to adjust the temperature. They can also adjust the air humidity, but it takes a humidifier.

Home air handling units are designed and produced in smaller dimensions than industrial air handling units because they must be installed in a more accessible environment.

3. Industrial Air Handling Units

Today, industrial air handling units are one of the best options among central air handling units. Industrial air handling units and other cooling/heating devices, such as water cooled or air cooled chillers and boilers, can provide the appropriate air temperature in large industrial and commercial environments.

In addition, in various industries, sometimes, during the production stages, there is a need for air flow with a certain temperature and humidity level. In such cases, industrial air handling units are a priority.

Let us again emphasize that air handling units cannot provide cooling or heating independently. Air handling units are a type of air distributor that can cool or heat the desired environment by using cold water from the chiller or hot water from the boiler of the engine room.

According to their type of use, such as in cinema centers, mosques, seminar halls, hospitals, etc., the air handling units can be equipped with special multi-stage filters, which come into operation through several stages to clean the air completely and even absorb pollutants.

Industrial air handling units are divided into 3 types in terms of application. However, they are pretty similar in terms of work relativity, but due to the different uses in some places, there are changes in the structure and components, which we will describe below:

3.1. Common Industrial Air Handling Units

A common industrial air handling unit has a cooling and heating coil and can be used in large commercial and industrial places such as factories. The fan of this device is of a forward-blowing type, and its filter is usually made of aluminum. Which mixes the inside air with a percentage of fresh outside air and cools or heats the air after directing it through the cooling or heating coil. Then, it is through the air channels implemented in the desired areas of the building.

3.2. Full Fresh Industrial Air Handling Units

FULL FRESH air handling units (providing 100% fresh air) naturally have stronger cooling and heating coils than normal air handling units because they must be able to cool all the hot air from outside. In addition to washable aluminum filters, these air-handling units have bag filters to help sterilize the air. The fan of this device is usually of the backward type and is suitable for use in places such as hospitals that need 100% fresh air with positive pressure.

3.3. Hygienic Industrial Air Handling Units

As its name suggests, a hygienic industrial air handling unit is suitable for operating rooms, server rooms, clean rooms, etc. Because in these places it is necessary to have cool and pleasant air, the air handling unit can provide clean and sterile air, free of bacteria. For this purpose, they use special filters called HEPA and ULPA.

Therefore, the complete air sealing of the body of hygienic air handling units is very important. In addition to using high-quality insulation, the device should be installed by an expert.

Comparison Table of Air Handling Unit Types

The table below provides a brief comparison of the most important parameters among industrial, residential (apartment), and hospital (hygienic) air handling units:

| Feature | Residential (Apartment) AHU | Industrial AHU | Hospital (Hygienic) AHU |

|---|---|---|---|

| Main Application | Common areas of residential and office buildings | Large industrial and commercial spaces | Sensitive areas such as hospitals, operating rooms, and clean rooms |

| Airflow Capacity | Low to medium (2,000 to 8,000 CFM) | Medium to high (8,000 to 60,000 CFM) | Medium to high with very precise control (8,000 to 40,000 CFM) |

| Unit Dimensions | Small to medium | Large | Large with specialized design |

| Fresh Air Supply | Limited or mixed | Mixed or 100% full fresh air | 100% fresh air |

| Filtration Type | Standard filter (aluminum or basic) | Aluminum filter + bag filter | Bag filter + HEPA / ULPA |

| Air Purification Level | Standard | High | Very high (sterile) |

| Temperature Control | Suitable for general requirements | Precise and adjustable | Highly precise and stable |

| Humidity Control | With auxiliary equipment if required | Controllable | Fully controlled and highly sensitive |

| Common Fan Type | Usually simple or constant speed | Forward or backward curved | Backward curved with low-noise design |

| Outlet Air Pressure | Low | Medium to high | High with positive pressure capability |

| Initial Cost | Lower | High | Very high |

| Maintenance Cost | Low | Medium | High |

| Need for Specialized Design | Medium | High | Very high |

Air Handling Unit Components

Air handling units mainly have components including insulated, insulated body, ventilation fan, electric motor, air filters, cooling and heating coils, humidifying sprayers, mixing box, inlet and outlet air dampers, and return air and control equipment; the most important which are listed in the followings:

Body and Insulation

The body of the air handling unit consists of three parts: chassis, frame, and walls. The walls of the air handling unit body include two parts, the inner wall, and the outer wall, the outer wall is made of galvanized sheet, and the inner wall is made of galvanized, aluminum or steel, depending on the use of the device, which is completely filled with special insulation between these two walls.

Fan and the Electric Motor

The blower fan supplies the energy needed to circulate the air inside the air channels of the building. In other words, the air handling unit fan takes the process of sucking the outside air into the device, passing it through the surface of the cooling and heating coils and the filtration system, and then transferring the conditioned air inside the units.

Among the fans used in air handling units are centrifugal fans and plug fans (forward or backward type). It is very important to pay attention to the power of the fan's electric motor to overcome the frictional pressure drop of the air volume passing through the main and secondary channels and air distribution valves in the desired environment.

Heating / Cooling Coils

Coils are an important part of air handling units in the airflow path, and the ambient temperature changes when the air passes through the cooling coils (in the summer season) and the heating coils (in the winter).

In the case of cooling and heating coils, in addition to paying attention to the required thermal level based on the cooling and thermal load calculations of the desired space, it is also important to consider the number of rows of fins per inch of the coil.

Air Filters

The air filtration system uses unique technologies to purify and clean the incoming air to the building units. Based on the type of technology and manufacturing standards, ingredients, and ability to remove pollutants, these filters include different types such as HEPA, ULPA, bag filter, metal pre-filter, fiberglass, and pleated (panel).

The type and number of filters used in each air handling unit are determined based on the level of air pollution in the project location and the level of sensitivity or necessity in using clean air.

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

Factors to Consider When Buying an Air Handling Unit

Here are the 19 most important factors that will help you determine and purchase the best air handling unit that suits your needs in any term:

- Single-area or multi-area

- The shape of the AHU (Horizontal or vertical)

- Type of the AHU (normal or hygienic)

- Location of the air handling unit (indoor or outdoor)

- Input & output air temperature

- Ducting Type (forward or upward blower)

- Climate Type (dry and wet)

- Total aeration rate (CFM)

- Height above sea level

- Type of the coil (DX or cooled water for cooling & electric, steam, or hot water for heating)

- Number of coils in a row

- Fin material and maximum density (FPI)

- Determining the design limitations of the air handling unit

- External static pressure required by the fan

- Type and number of air filters

- Type of return, fresh, and supply dampers, along with their actuator

- Required accessories (humidifier, smoke and fire detector, pressure and temperature gauge, temperature and humidity sensor)

- Material type and thickness of the body

- Type of coating/paint

Explanation: Air handling units with a DX coil use refrigerant gas to provide cooling instead of cold water in their cooling coils.

Notes:

- Determining the role of the coil in air handling units, pay attention to the number of rows, thermal surface, and fins per inch of heating and cooling coils, as well as the diameter and thickness of the coil, body sheet, and frames of the device.

- Having a humidity-increasing system or not having one.

- To calculate the cooling and thermal load of the area accurately, the mentioned factors should also be examined by the engineers or experts of the DamaTajhiz HVAC Group.

The New Generation of Air Handling Units

The new generation of air handling units provides optimal performance and high efficiency by using modern design, advanced and precise manufacturing technologies, high-quality components, and smart features. The following are some of the features and advantages of the new generation of air handling units:

Lower Energy Consumption

One of the prominent features of the new generation of air handling units is the reduction of energy consumption. These units reduce energy use by employing high-efficiency motors and fans, smart management systems, and continuous airflow management technologies.

Precise Temperature and Humidity Control

The new generation of air handling units has capabilities for precise control of temperature, humidity, and air distribution, allowing project managers to determine and effectively manage the desired temperature and humidity conditions for various environments.

Lower Noise and Sound

The new generation of air handling units, with optimized designs, sound-absorbing materials, and the use of silent fans and motors, prevent the generation of noise and sound in buildings.

Compatibility with Smart Controlling Systems and Automation

The new generation of air handling units can connect to smart and automated systems, allowing for remote and intelligent operation and control of the units.

Air Quality Protection

The new generation of air handling units, using high-quality and replaceable filters, complete body sealing, and the ability to eliminate harmful and suspended particles in the air, ensure optimal air quality.

Lower Installation and Maintenance Costs

Due to the design and use of modern and optimized equipment in the new generation of air handling units, operational, repair, and maintenance costs have been reduced. Additionally, the use of replaceable parts and easy repairs contributes to this matter.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

Choosing the Best AHU Cooling / Heating Load Based on the Climate

One of the most important factors in calculating the cooling and thermal load of the air handling unit is its type in terms of the required temperature and humidity in different climates, such as:

- Hot and Moderate Climates: Cities such as Tehran, Semnan, Karaj, Mashhad, Shiraz, Isfahan, Sulaymaniyah, Kirkuk, Mosul, Aleppo, Erbil, Damascus, Beirut, etc.

- Hot and Humid climates: Ahvaz, Bandar Abbas, Chabahar, Karachi, Basra, Dubai, Sharjah, Muscat, Abu Dhabi, Jeddah, Sanaa, Aden, and Doha.

- Hot and Dry Climate: Cities include Yazd, Kerman, Zahedan, Zabul, Baghdad, Karbala, Najaf, and Islamabad.

- Cold and Moderate Climates: like Tabriz, Urmia, Yerevan, Ankara, Khujand, Samarkand, Dushanbe, and Ashgabat.

- Moderate and Humid Climates: Cities such as Rasht, Baku, Sari, Antalya, and even the cities located in cold and dry climates and weather conditions, which are naturally used in heat load calculations and the cooling of the project, will have a very high impact.

Air Handling Units Cooling / Heating Load Based on Ducting

The calculation and implementation of air distribution channels (in addition to using galvanized sheets with suitable thickness), insulation of the channel, implementation of appropriate fasteners and supports, and channel dimensions at each section of the route.

As well as the determination of the appropriate speed of air passage, compliance with the standards for changing the direction and the internal radius of the arches in the air transmission channels, and finally, the dimensions of the air outlet valve in each space with the appropriate speed.

Necessarily, according to engineering calculations, using duct workers and complying with the design and calculation standards of air transmission ducts under the supervision of engineers should be done.

Air Handling Unit Accessories (Optional)

Considering the special importance of important equipment such as an air handling unit in providing the desired temperature, humidity, and air quality in projects and buildings, naturally, special equipment and accessories can be considered to improve the performance and quality of the output air of this equipment, the most important of which are presented as follows. :

- Using Blue Fin coil or Gold Fin coil to improve and increase heat exchange efficiency as well as the useful life of the air handling unit.

- Installation of a three-way motorized solenoid valve (base) with transformer, motor linkage, and sequential channel thermostat to adjust the flow rate and bypass of the water entering the cooling coil and also the heating coil of the air handling unit based on the temperature requirement at every hour of the day and in every season of the year.

- Hepa and Olpa filter to purify the air coming out of the device as much as possible and improve the quality of the air coming out of the air handling unit as much as possible based on the needs of the project and the client's request.

- Implement a humidification system for some projects such as greenhouses, mushroom cultivation halls, sensitive treatment centers, etc., using a pump and a network of pipes and water nozzles installed inside the air handling unit and a humidistat humidity control system in the outlet air channel.

- Silencer to reduce the sound of the air handling unit fan, especially in high capacities in sensitive hospital, commercial, and residential projects, to provide more comfort and well-being for the users and residents of the project.

Temperature Control Process of an Air Handling Unit

Basically, in air handling units, temperature control is done in the following three ways:

1st Method: Three-way Electro Motor

Use an electric three-way valve or a motor installed on the return pipe of the air handling unit's cold and hot water coil and a thermostat installed in the air return channel to the air handling unit. The operation of disconnecting and connecting or increasing and decreasing the flow of hot water or the cold water of the coil is used to adjust the ambient temperature.

2nd Method: The Thermostats

It is installed in the room, corridor, or another suitable place to control some basic commands, such as the ON/OFF command and fan coil mode of the thermostat. The control system must be designed so the channel thermostats and three-way valves work first. Then, in the next step, if necessary, the room thermostat gives an order to the ventilation fan to change the speed.

3rd Method: Damper Motor

The air coming out of the air handling unit is controlled by a damper motor installed in the way of the fresh air inlet and mixed with the return air to adjust the desired temperature according to the thermostat's temperature data.

It is technically necessary to install a flow switch in the outlet water path of the evaporator (Chilled Water) towards the cold water coil of the heat exchange equipment to give a Stop command to the chiller when the circulator pumps of the cooling circuit are turned off.

Air Handling Unit Installation Tips

Here are the 6 installation tips that, if you follow, you can get the most out of your air handling unit:

- In large air handling units due to the large dimensions of the air handling unit, it is not possible to transport them easily, so large air handling units are first transported in disassembled form (separated parts) and reassembled at the installation site.

- Air handling units of galvanized sheets may be made vertically or horizontally according to the location and installation position. Air handling units are designed and manufactured in a single-zone or multi-zone way. In the one-zone type, all parts of the building covered by the air handling unit are ventilated with uniform temperature and humidity. In multi-zone air handling units, with the help of special dampers, it is possible to aerate with different temperatures and humidity to different areas of the building.

- The foundation of air handling units should be considered according to the project's structure, the device's weight, and dimensions.

- To make it possible to replace the coil of the air handling unit after its long period of operation, according to the engineering standards, it is necessary to consider a space equal to 1.5 times the width of the device at the place of installation of the air handling unit on one side.

- It is technically necessary to consider the sewer drain in the air handling unit room for cleaning and periodic services.

- One of the important points in operating and maintaining the efficiency and effectiveness of air handling units is to perform proper insulation, especially on the ducts outside the building, which are exposed to sunlight and heat in summer and cold in winter.

Buying an Air Handlin Unit

To buy a DamaTajhiz air handling unit or from other brands, you must first determine the required air handling unit's thermal and cooling load capacity, aeration volume, and technical specifications. On the website of DamaTajhiz HVAC Group, technical information of dozens of air handling units from reputed brands with their main guarantee has been presented so you can enjoy the good feeling of optimal and smart shopping.

Air Handling Unit Price

The price of an air handling unit can vary largely based on the capacity, mode, brand, and other specifications. Different types of air handling units with different qualities and prices are available on the website of DamaTajhiz HVAC Group; all have reasonable prices and discounts already included.

Factors Affecting the Price of Air Handling Units

The price of an air handling unit is one of the key considerations when selecting this type of HVAC equipment. Due to the wide variety of models and applications, it is not possible to define a fixed price for each AHU capacity. In fact, the cost of residential, industrial, hygienic, and other types of air handling units depends on several factors, which are outlined below:

- Unit Capacity: The airflow capacity of an air handling unit, typically expressed in CFM, plays a major role in determining its price. As the capacity increases, the unit’s casing dimensions, electric motor power, fan performance, coil size, and energy consumption also increase, leading to a higher overall cost.

- Type and Application:The second key factor affecting the price of an AHU is its type and intended application. Residential air handling units usually feature a simpler design and smaller dimensions and are intended for residential and office spaces; therefore, they are more affordable than industrial and hygienic models. In contrast, industrial and especially hygienic AHUs involve higher costs due to the need for high precision, specialized components, and compliance with strict standards.

- Cooling and Heating Coils: The surface area, number of rows, tube type, tube diameter, and fin density (fins per inch) of the cooling and heating coils installed in the AHU significantly affect its price. These factors are closely related to copper and aluminum prices as well as coil manufacturing and assembly costs.

- Control Systems and Accessories:The inclusion of advanced control systems, inverters, temperature and humidity sensors, motorized dampers, energy recovery systems, and humidification or dehumidification equipment all have a direct impact on the final price of an air handling unit. The higher the level of control and intelligence, the greater the manufacturing cost and, consequently, the unit price.

- Filtration Level and Supply Air Quality: The type and number of filters used in an air handling unit are among the most important factors influencing its price. Basic aluminum filters are less expensive than bag filters, HEPA, or ULPA filters. In hygienic AHUs, where fully clean and sterile air is required, the use of comprehensive and advanced filtration systems leads to a significant increase in unit cost.

- Brand and Build Quality: The manufacturer’s brand and the quality of materials used in the casing, coils, and fans also play a decisive role in the price of an air handling unit. Reputable brands typically use more durable metal sheets, better casing insulation, and longer-lasting components, which results in noticeable price differences between various AHU models.

Can a fan coil be used instead of an Air Handling Unit?

Air handling units are usually more useful than fan coils in humid areas. In addition to improving the quality of the outgoing air, installing fan coils requires implementing a wide network of back-and-forth piping and drains in the building, and the humidity of the environment and the ground also causes early decay of the pipe network. The fan coils are installed in the building, while the channels of the air handling unit, usually installed on top of the false ceiling, have a much longer lifespan than the pipes installed on the building floor.

Dear user

If, after reading the above article, you have more questions about purchasing vertical and horizontal air handling units, you can contact DamaTajhiz HVAC Group and receive advice from the air conditioning equipment sales experts and ask your questions.

In the group of air handlers of DamaTajhiz specialized collection, technical information of dozens of models of air handlers from reputable companies has been presented for you, dear experts and employers, to review and buy from an expert air handling unit supplier.

Also, because DamaTajhiz, as an official member of the Heating and Air Conditioning Equipment Dealers Association, provides all types of air handlers in the Middle East region, if you need an Air Handling Unit (AHU) for any of the countries in the region, you can place your purchase order with confidence. Leave product warranty and reasonable price to our sales experts.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.