Water Tank

Water tanks are used to provide and store hot water for use in buildings. The following review of the specifications, capacity, dimensions, selection guide, and the best purchase price of all coiled and double-walled water and fuel storage tanks.

Water Tank Expert Selection Guide and Price List

There are two main types of liquid tanks: water and fuel tanks. However, they come with their subtypes based on the working temperature and pressure, which we will expand on in the following.

How the hot water tank (indirect water heater) works is to use the heat energy of hot water or steam from the building's central heating boiler and enter it into the coil installed inside the source and transfer this heat energy to the cold water entering the main tank of the coil source (such as a heat exchanger) for both hot and cold water.

DamaTajhiz: The First Specialized Reference for Selection and Pricing of HVAC and Building Equipment (Since 2004)

Types of Water Tanks

There are two types of water tanks, which are divided by the temperature of the water inside them:

Hot Water Tank

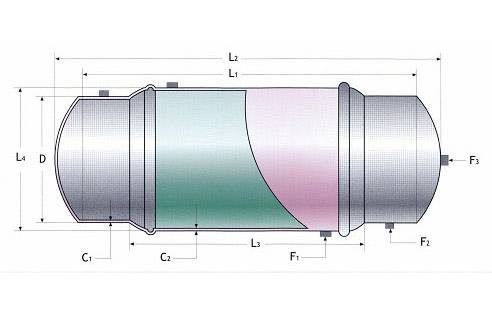

A coiled hot water tank, which is produced in two types, standing and horizontal, is used in central heating systems of buildings to produce hot water for consumption and health (from cold water entering the building).

They are produced and supplied vertically and horizontally, usually from 400 liters to 8000 liters capacity. For sanitary and washing purposes in homes and even industrial works, the best temperature is between 40°C and 55°C, which is the best option for providing hot water for the building.

The heating mechanism of the spiral water tanks is to use the heat energy of the hot water or steam from the engine room's boiler and direct it into the coils inside the tank and transfer this heat energy to the cold water entering the tank (just like a heat exchanger) for consumption, heating pool water, and other purposes.

Hot Water Tank Benefits

Four reasons why a coiled tank is a great choice for every type of building:

- If the lowest part of the horizontal spiral water tank is above the collector level of the engine room boiler, the supply of hot water can be done without using a circulator pump.

- The body material of coiled tanks is usually made of a hot galvanized sheet. Still, if a hot-rolled steel sheet is used, to prevent it from rusting and oxidizing, the inner surface of the tanks is completely covered with epoxy paint, and the outer surface of the tank is covered with high-quality oil paint to prevent rusting.

- The superiority of coiled water tanks over double-wall tanks is the ease of repairs due to their single-wall (in case of leakage), faster heating, and higher efficiency due to the presence of a coil inside of them.

- Coiled water tanks are made in vertical and horizontal models based on the calculation and order of the customer for installation in the engine room of hotels, hospitals, residential and office complexes, factories, swimming pools, etc.

Double-Wall Hot Water Tank

A double-wall hot water tank is an indirect heat exchanger that heats water without any direct contact with the boiler's water or the burner flame. Double-wall tanks are usually produced with a 300- to 1200-liter capacity and are installed in the engine room of buildings.

Double-Wall Water Tank Pros & Cons

One of the features of double-walled tanks is to heat a large amount of water in a short period even without using the engine room hot water circulator pump (due to the gravity flow of hot water going back and forth from the boiler), which makes it suitable for places like residential apartments, offices, swimming pools, and all places that need constant hot water.

One of the disadvantages of double-walled tanks is that when a small hole or leak occurs, it is typically not possible to repair it, and it is typically difficult to repair such tanks.

Double-walled tanks in different capacities based on the needs of buildings, from 300 liters to 1500 liters, are manufactured and supplied horizontally (or horizontally).

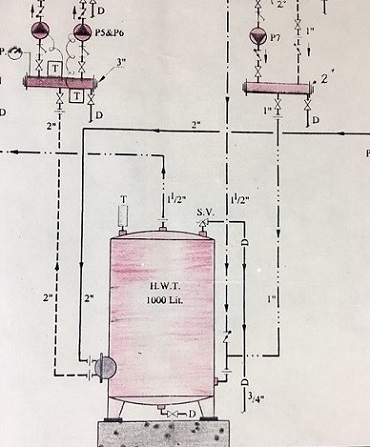

The Schematic Diagram of the Standing Coiled Water Tank Plumbing

Double-Wall Hot Water Tank with Hot Galvanized Sheet

A double-wall tank is installed in the engine room to heat the required water for the building. These tanks are made in two layers in which the hot water of the boiler flows between the two walls and heats the cold water inside.

Due to the higher pressure of the inner part of the tank, which is caused by the city water pressure, the thickness of the galvanized sheet of the inner wall should be greater than the thickness of the galvanized sheet of the outer wall, where only the hot water of the boiler flows.

Note: Two numbers indicate the thickness of the double-wall tank's sheet; for example, the 3-5 double-wall tank indicates that the thickness of its inner wall is 5 mm and the thickness of its outer wall is 3 mm.

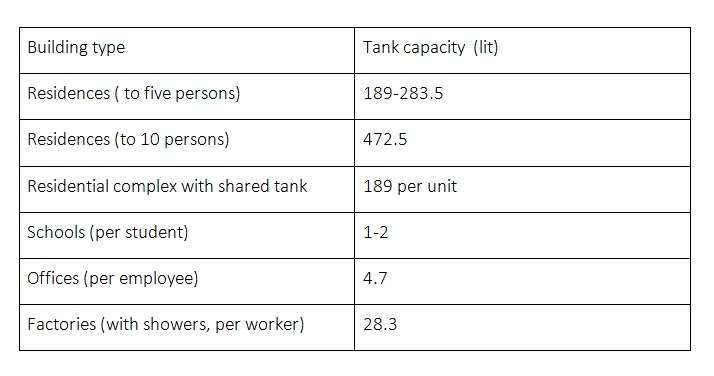

Hot Water Tank Capacity Estimation

To estimate the capacity of the building's water tank (coiled or double-wall tank), considering the number of units, the building's usage, the demand factor, the simultaneity factor, and the consumption factor, approximately 100 to 200 liters of tank capacity for each residential unit.

It is recommended that the experts do the estimation and calculation based on a few factors, such as the volume of the required hot water tank, the thickness and type of body sheet and lenses, and the dimensions of the spiral tank (in terms of the possibility of entering and installing it in the engine room), especially in terms of calculating the height of the standing tank with a base and on the foundation.

Regarding the calculation of the heat exchange level of the coil in the tank, as a general rule, it can be said that to calculate the amount of the heat exchange level of the spiral tank.

The total heat required by the tank (according to the volume of the tank and the temperature difference between the input cold water and the output hot water) divided by the overall heat transfer coefficient (U type) is multiplied by the logarithmic temperature difference of the inlet and outlet water.

Hot Water Tank Sheet Thickness Calculation

Keep in mind the following points to choose the best water tank for your needs:

The Working Pressure

The correct calculation and determination of the thickness of the steel sheet used in the construction of a coiled hot water tank, double wall tank, fuel storage tank, etc., is done based on the working pressure (water pressure inside the tank) as well as the international standards of pressure vessels (tank under pressure).

Among other factors that are important in determining the correct thickness of the sheet of the water tank, the working temperature (temperature of the fluid inside the tank) and the corrosion coefficient of the water used in the tank can be mentioned.

The Working Temperature

According to engineering standards and tables, the temperature of sanitary hot water used in buildings is usually between 50 °C and 60 °C. Therefore, the temperature of sanitary hot water stored in a coiled tank or a double-wall tank should not be less than 50 °C.

If the temperature of the hot water in the source is lower than this temperature, a special green bacteria called Legionella, which has a suitable temperature for growth and reproduction between 25 and 50 degrees Celsius, will grow in the source, which will lead to pollution and consequently costs. Periodic extra washing of the source and removal of this bacteria interferes.

Suppose the temperature of the hot water in the tank is lower than this. In that case, a special green bacteria called Legionella will grow in the tank, which will lead to pollution, as the periodic extra washing of the tank and removal of this bacteria will not be cheap.

The Coating & Painting

Epoxy paint with a thickness of 140 microns or cold zinc (even if galvanized sheets are used) is mandatory in the welding place of coiled and double-walled hot water tanks.

According to the 16th topic of the National Building Regulations and the recommendation of the Engineering System Organization, the water consumed for 12 hours must always be stored due to the average water usage of 150 liters per person in 24 hours.

The installation location

The water tank must be placed at a height and often on the roof of the building so that the gravity force can help to pressure up the water. Therefore, it is recommended to use 2 storage tanks with lower capacity due to the concentrated weight on one spot.

For example, for a building with 20 office units, each of which has an average of 4 residents, two 1500-liter cold water storage tanks with a 3000-liter water storage tank should be used based on the ability to bear the load of the building's roof structure.

Cold Water Tank

There are five types of cold-water tanks based on the material and installation position:

- Horizontal Cold Water Tank: This type of cold water tank has a low height and can be installed in spaces that have height restrictions.

- Vertical Cold Water Tank: This type of tank can be used by occupying the lowest level in places that do not have height restrictions.

- Square Cold Water Tank: This type of tank, with its special geometrical shape, occupies the least amount of space and has the possibility of implementation and installation in unused spaces while providing a significant volume of water storage.

- Horizontal Modular Tank: This type of tank is specially produced in two forms, light and heavy, with the ability to be used in septic tanks and wastewater treatment packages.

- Polyethylene Cold Water Tank: This type of tank is used to store water and a wide range of fluids. These tanks, which have 2, 3, and 5 layers, are also known as plastic tanks, generally used in apartments, villas, buildings outside the city, and agricultural, chemical, and food industries for storing and transporting water and other liquids.

Polyethylene Tank Benefits

Poly tanks can have many advantages, some of which are listed in the following:

- Relatively low weight

- A long lifespan

- Corrosion resistant

- Easy to transport

- It can be produced in various forms.

- In terms of design and appearance, they are more beautiful than other tanks.

- The price of a poly tank is lower than other tanks.

- Polyethylene tanks can be used to store a wide range of liquids.

- In some poly storage tanks, due to the presence of anti-UV materials, they are very resistant to the destructive effect of the sun's ultraviolet rays.

Poly Tank Applications

Poly tanks are usually used in the following situations:

- Sanitary tank to store drinking water

- Domestic sewage collection tank

- Storage tank for chemicals

- Oil storage tank

If the water is for consumption:

- Colorless and single-layer tanks are suitable for storing cold water in a covered space.

- Two-layer tanks without insulating foam are suitable for storing water used outdoors in temperate regions.

- Three-layer and four-layer foamed tanks are more suitable for storing water used outdoors in tropical and cold regions.

Water Tank Implementation Tips

Follow the following tips so you can get the most out of your storage tank:

- Installing a safety valve (temperature and pressure) is necessary for all types of hot water tanks, such as spiral and double-wall tanks.

- It is necessary to extend the water head pipe from the open expansion tank on the roof to the engine room.

- When installing a horizontal or vertical coiled hot water tank, pay attention to the possibility of removing the coil for service and repairs.

- When installing a storage tank, be careful not to puncture it because the water will penetrate the heating system of the building. As a result, the water overflows from the open expansion tank on the roof of the building.

- Installing a suitable vent pipe for ventilation is necessary for all diesel storage tanks.

Buying Water Tanks

When ordering a water tank, the volume of the tank and its type are of great importance. To choose the right storage tank, you must first determine the volume, dimensions, material, and working pressure of the desired tank.

On this website, technical information on dozens of water tanks from reputable brands with the authenticity guarantee has been presented so that you can enjoy the good feeling of optimal and smart shopping.

Also note that in the specialized HVAC group of Damatajhiz, all the fuel and hot water storage tanks are only sold in bulk. Therefore, if you want to wholesale these products, contact us.

Note: Before finalizing the order of the required galvanized or polyethylene water tank, in addition to paying attention to the type and capacity of the required water storage tank, pay special attention to the critical point of the dimensions of the customized tank. So you will not face problems such as the impossibility of passing through the entrance door of the building, the roof door, the entrance door of the engine house, or the problem of the dimensions of its location right after you receive the product.

The Price of Water Tanks

Browse and examine all types of storage tanks at the best price on the website of DamaTajhiz HVAC. The price of different hot/cold water and fuel tanks varies based on the numerous models, types, and brands available.

All types of storage tanks presented on the website of DamaTajhiz have reasonable prices with a generous discount already included on them. Therefore, the best price for all types of storage tanks is guaranteed for wholesale purchase.

Dear Users

While thanking you for your confidence in the technical opinions of the DamaTajhiz sales experts, it should be noted that the buyer ultimately determines the choice of the desired product brand based on history, brand strength, service, and price.

But most users and buyers of storage tanks choose and buy best-selling brands such as DamaTajhiz coiled and double-wall storage tanks and poly tanks of Tabarestan according to their quality, price, and after-sales service.

After reading the above material, you have more questions to decide on the type of storage tank you need; you can contact the heating equipment and engine room department experts after contacting DamaTajhiz and extension numbers 107-108-121-122. Get advice and ask your questions.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.