Level switch

As you know, the main prerequisite for doing any work is to have proper information about that subject. Regarding selection, checking prices, buying and know more about level switches, the contents are included below so that you, dear visitors of the specialized website of Damatajhiz, can use these tips to choose and buy different types of diapason, capacitive and float type level switches from brands Krone, Siemens, Anders Havers, Ayew Teknik, Mehrsam, etc. in bulk.

User manual and introduction of level switches

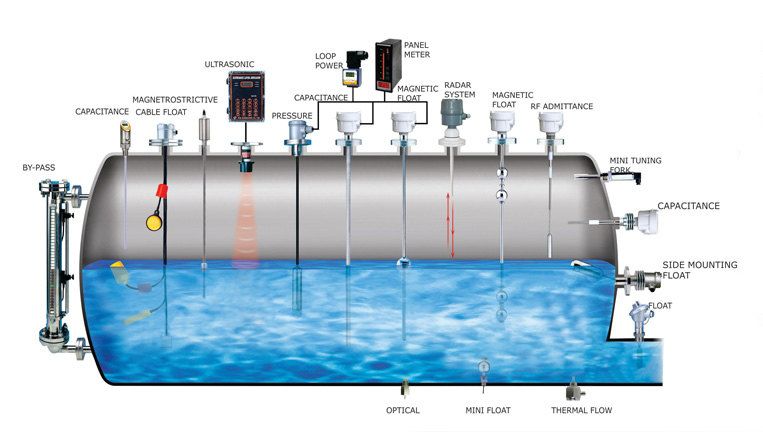

Generally, level switches are used to measure the level and height of different fluids. The level switch acts as a fluid level controller and can detect the level of different fluids and even powdery solids. The level switch consists of two main parts, one is in direct contact with the upper level of the fluid, and the other is calibrated at the standard level. The level switch will warn when the distance between the two parts of the level transmitter is greater or less than the standard. For a better understanding of the function of the level switch, we can refer to the simple function of the more relaxed float, which keeps the amount of water at a certain level. Different types of level switches, such as vibration, radar, resistance, capacitor, etc., are used in various industries depending on the type of function. Join us in introducing and checking the function of level switches in the rest of this article (for wholesale purchas).

Types of level switches in industry and facilities

- Optical switch level

- Vibration or range switch level

- Buoyancy switch level

- Capacitive switch level

- Radar switch level

- Resistance switch level

- Mechanical switch level

- Diaphragm or membrane switch level

- Ultrasonic level switch

- Vane or pedal switch lever

- Nuclear or point-level switch

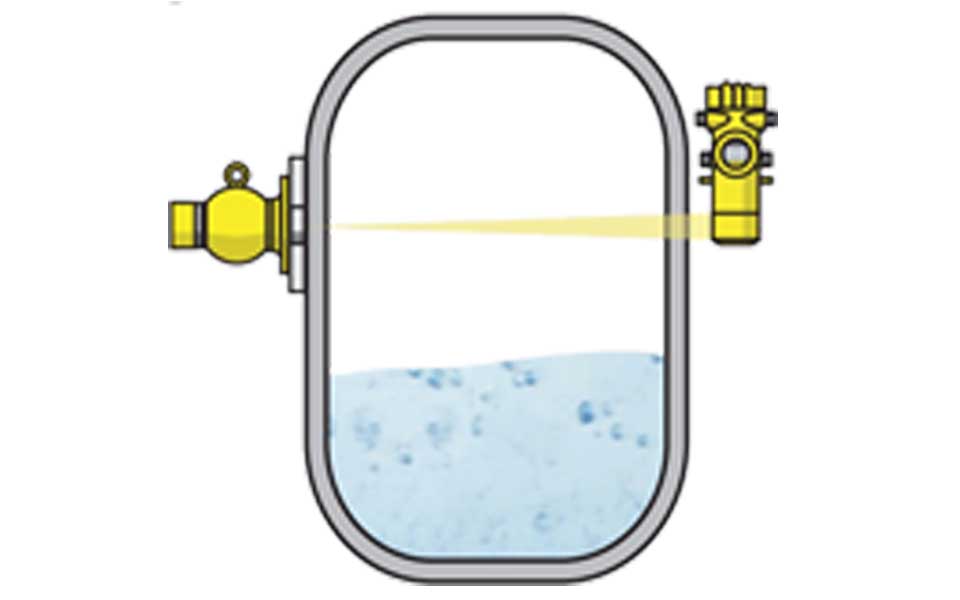

Optical switch level

The level of the optical switch consists of an LED sensor and a photonic transistor. The sensor's tip is near the air, and a small prism is mounted. As long as the front part of the sensor is transparent, the light reflects in the prism and returns to the receiver. But when the liquid stops in the sensor, the light passes through the prism, the sensor detects the liquid, and the switch is disconnected or connected. These level switches are small, durable, and resistant to high pressure and temperature, but they can detect small liquids.

Capacitive switch level

The capacitive level switch has two plates that measure the level changes by changing the capacitance between the two plates. There are two types of capacitive level switches, capacitive level switches for liquids with high dielectric constant and capacitive level switches for liquids with low dielectric constant. These level switches work with a wide range of liquids and solids and are both contact and non-contact. These level switches are small and accurate and are widely used in water, food, aquatic and chemical industries.

Ultrasonic level switch

Ultrasonic sensors send high-frequency sound waves to the fluid and measure the level by calculating the duration and strength of the return waves from the fluid surface. These level switches are small and used in systems requiring remote control. The ultrasonic switch lever cannot be in contact with sticky solids.

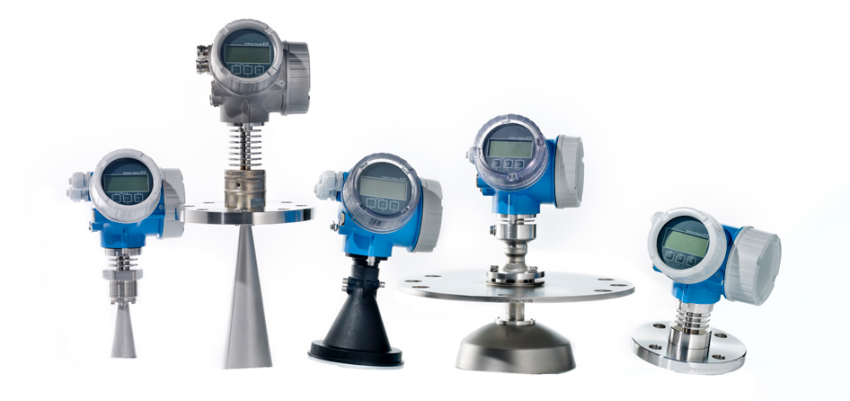

Radar switch level

The operation of the radar level switch is similar to the ultrasonic level switch method, with the difference that the pulses move at the speed of light and with repeatability. The advantages of the radar level switch include the flexibility of working in wet and dusty environments, no need for calibration, high accuracy, different outputs, and working in systems with different temperatures.

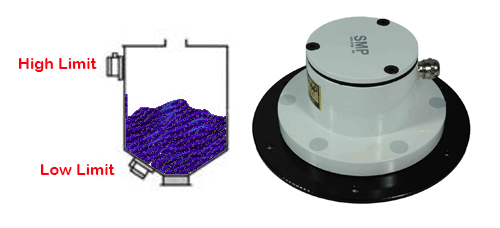

Vibration or range switch level

Tuning fork level switches, also known as range or vibration switches in Iran, are among the most accurate level switches used in various industries. Some of their models are even designed for use in explosive environments.

Vibronic level switches measure the level of solids and liquids based on the tuning fork's scientific principle, which John Shore proposed about 300 years ago. In 1987, the Endress Hauser company designed and produced vibrating level switches for the first time based on the scientific principle of tuning forks. In this scientific principle, the amount of surface is checked based on the direct relationship between damping fluctuations in fluids.

The forks of the sensors of this model of level switches are generally oscillating and often oscillating at the resonance frequency. When the fluid surrounds and covers the space between the forks, it changes the oscillation frequency of the forks; As a result, the sensor detects that the liquid level has risen.

Different components of vibration or range-level switches

Vibronic or diapason level switches measure the point level of fluids inside tanks and pipes. In this sensor, two rakes oscillate at a resonance frequency, stimulating a piezoelectric system. This piezoelectric system has the following two types of piezo electronic drives:

Drive-By Morph

Bimorph drive has two types of piezo disk and ceramic disk, which are connected. Connecting and disconnecting the voltage of ceramic and piezo discs causes oscillation in the tuning fork.

Drive stack

In the drive stack, three piezo disks are connected and fixed; The voltage connection and polarization change in the disks cause oscillation. Next, the disks are connected to the membrane, the membrane is connected to the tuning forks, and finally, the oscillation is transferred to the tuning forks.

How vibration or range level switches work

When the fluid rises, it changes the resonant frequency of the tuning forks; This change announces the presence of a spot of fluid and causes the corresponding switches to operate.

Only the stack piezoelectric drive is used when measuring solid surfaces. The accumulation of material around the tuning forks causes the oscillation's damping and changes the oscillation's amplitude. As a result, it notices the presence of fluid, and the switches work.

Resistance switch level

The resistance level switch consists of two metal probes, one with a long length and the other with a short length, and they are placed in the tank, and when the probes come into contact with the liquid, a current is established in both probes, and the switch is activated. One of the advantages of the resistance level switch is its use for liquids with sensitive or corrosive conductivity. These level switches are not suitable for explosives; the probe is erasable, and the liquid must be electrically conductive.

Buoyancy switch level

The float switch valve has a float valve consisting of a float, a magnetic switch, and a magnet. As the float moves in and out of the liquid, the liquid level is detected, and the switch operates. This switch is cheap and widely used and is used in tanks containing water, oil, chemicals, and hydraulic fluid, with different outputs.

Vane switch lever

The vane switch lever has a vane rotated by an electric motor. When the material level inside the tank reaches the rotating vane, the metal vane stops rotating, the motor moves from its axis, and the micro switch is activated, resulting in a signal indicating whether the tank is full or empty and the level of the material inside it. This level switch is used to control the level of powder and granular tanks and is used in industries such as cement, food, petrochemical, etc.

Diaphragm switch level

Diaphragm level switches are mainly used to control the level of porous materials and solids and sometimes to control the level of liquids used in food and petrochemical industries. These level switches can be used in high-temperature and explosive environments.

Nuclear switch level

The nuclear level switch is also used to control the fluid level inside the tanks. In this way, the command to stop or connect the fluid flow to the tank is given when the fluid level reaches a specific value.

In the level switch group of the reference site and Damatajhiz store, you can view the information and prices of all types of level meters or level gauges, including float level gauges, range gauges, etc., from Anders Hauser, Fantini, etc. brands for review and selection.

In addition to a valid business license from the heating and air conditioning trade union, DamaTajhiz has an electronic trust symbol and started operating its store site in 2013 in the head office of Tehran.

Order from you, follow up from us.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.