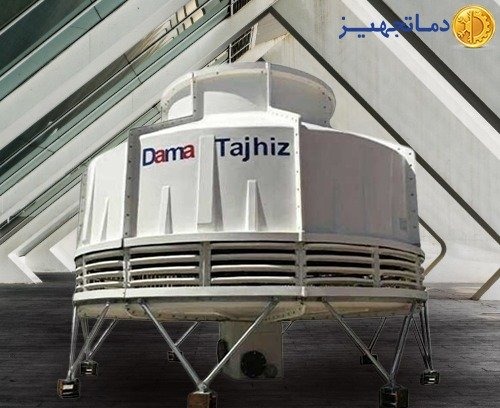

DamaTajhiz Fiberglass Cubic Cooling Tower DTC-CO 80

- Motor Power: 1.5 HP

- Normal Water Flow Rate: 282 gallons (1.07 m³) per minute

- Material: Fiberglass

- Dimensions (Height × Length × Width): 340 × 180 × 180 cm

- Fill Type: Net Splash Packing made of P.P or pharmaceutical-grade P.V.C packing as per buyer’s choice

![]() Delivery Time: (Coordination with sales experts)

Delivery Time: (Coordination with sales experts)

✔️ Pre-Sales Services:

-

Engineering consultation + calculations and capacity determination

(Providing specialized consultation, technical calculations, and precise determination of the cooling tower capacity)

Guide to Purchasing 80 Tons DamaTajhiz Cubic Fiberglass Cooling Tower

The design of the DamaTajhiz Cubic Fiberglass Cooling Tower 80 Tons is based on COUNTER FLOW air circulation TYPE. In general, DamaTajhiz cooling towers are used to cool water (reduce water temperature) circulating in water-cooled HVAC condenser systems, industrial processes, power plants, refineries, and more.

DamaTajhiz cubic fiberglass cooling towers are manufactured in different capacities according to international standards and modern technologies. They feature proper dimensions, sufficient fiberglass body thickness, and maximum packing volume. Thanks to advanced technology in water spraying and distribution, these units provide superior performance, reduced water consumption, and easier service compared to other models available on the market.

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

Performance of Cubic Cooling Towers

- As air circulates inside the cooling tower and cools the circulating water, part of the water in the cooling tower evaporates. After cooling, the water is collected in the basin at the bottom of the tower and is pumped back to the chiller or the production process.

- In general, the calculation and design of cubic cooling towers for HVAC are based on inlet water temperature of 95 °F (ca. 35 °C), outlet chilled water temperature of 85 °F (ca. 29 °C), and an ambient wet bulb temperature (W.B.T.) of 75 °F (ca. 24 °C).

- The minimum outlet water temperature of cooling towers depends on the wet bulb temperature of the installation site during summer. Normally, outlet water temperature is about 2.5 to 3 °C higher than the wet bulb temperature of that location. For example, in Muscat, where the summer wet bulb temperature is 23.8 °C, the cooling tower typically delivers water at about 26 °C.

- The DamaTajhiz Cubic Fiberglass Cooling Tower 80 Tons is of suction type, where air circulation can occur naturally or forcibly. Forced suction is achieved by an AXIAL fan located at the top of the cooling tower.

Body and Basin of the Cubic Cooling Tower

- The body parts of the DamaTajhiz cubic cooling tower, including the DamaTajhiz Cubic Fiberglass Cooling Tower 80 Tons, are made of reinforced fiberglass with high strength, protected against UV rays with two external coating layers.

- The body and basin parts are easily assembled for annual servicing. Secondary connections are made from non-metallic materials such as PRC, FRP, ABS, or stainless steel and aluminum.

- Fibers: The base fibers used in the fiberglass parts of DamaTajhiz cooling towers are woven mesh fibers. In addition, needle mat fibers are used to further reinforce the structure.

- Resin: The base resin used in the fiberglass parts of DamaTajhiz cooling towers is unsaturated polyester resin, isophthalic type, brand BKC, certified by SGS ISO9001 quality management. The resin code is 2200.

- The basin (BASIN) of the DamaTajhiz cooling tower is a one-piece fiberglass (F.R.P) unit, 10 mm thick, reinforced with two additional mat layers compared to the panels, and lined inside with two layers of UV-protective vinyl ester gel coat.

- The fans used in DamaTajhiz cubic cooling towers are made of Multi-Wing material.

Electric Motor of the 80-Ton Cooling Tower

The electric motors of the DamaTajhiz cubic fiberglass cooling towers are mainly from Motogen factory, with IP54 protection and long service life.

The DamaTajhiz cubic cooling tower is designed and manufactured as a low-noise model that meets standard sound levels. Ultra-low-noise design and manufacturing are also available, making these towers unique in dimensions and cost compared to others.

Review, Selection, and Pricing of HVAC Equipment

Packings in the 80 Tons Cubic Cooling Tower

- The DamaTajhiz Cubic Fiberglass Cooling Tower 80 Tons is equipped with two rows of net splash packings.

- The packing sheets of various DamaTajhiz cooling towers are corrugated and stacked in a honeycomb structure. The grooves are designed in sinusoidal form, preventing clogging, while creating a suitable medium for water film formation, rapid evaporation, and greater surface contact with air, maximizing heat transfer. DamaTajhiz cooling tower packings are usually 19 mm film type made of PVC with a special antibacterial coating, medical grade (FDA approved), with 400-micron thickness, or splash/random splash packings made of first-grade PP, antibacterial, medical grade, with 500-micron thickness.

- To minimize drift or water droplet carry over from the top of the DamaTajhiz Cubic Fiberglass Cooling Tower 80 Tons, PP eliminators are installed above the nozzles. These blade-type eliminators reduce water drift to less than 0.002% of circulating water.

Water Distribution System in DamaTajhiz Cooling Tower

In the DamaTajhiz Cubic Fiberglass Cooling Tower 80 Tons, inlet water enters through central pipes made of polyethylene or PVC into water distribution nozzles, spraying uniformly over the tower packings. (The type of nozzle is selected based on the climate conditions of the installation site and customer requirements.)

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

Supporters of the DamaTajhiz 80-Ton Cubic Fiberglass Cooling Tower

- The supports of the DamaTajhiz cooling towers are made of hot-dip galvanized steel.

- For models up to 175 tons, the supports are made of fiberglass. For higher capacities, hot-dip galvanized steel supports are used.

- The DamaTajhiz cubic cooling towers comply with O.S.H.R mandatory standards. To access the mechanical and electrical parts on the tower, hot-dip galvanized steel ladders are installed.

- The fan stack support chassis is made of 6 mm galvanized steel sheet. Fan guard meshes are made of hot-dip galvanized iron with coating thickness ranging between 83 and 110 microns. Motor bases and chassis are also constructed from hot-dip galvanized angles.

- The panel supports, tower floor chassis, outer supports, and external holders are all made of hot-dip galvanized iron with 150-micron zinc coating.

Eliminator (Drift Eliminator) of the 80-Ton Cooling Tower

To minimize drift or water droplet carry over from the top of the DamaTajhiz Cubic Fiberglass Cooling Tower 80 Tons, PP eliminators are installed above the nozzles. These blade-type eliminators reduce water drift to less than 0.002% of circulating water.

Components of DamaTajhiz Cooling Tower Fan

- Fan Blade: In DamaTajhiz counterflow cooling towers, the fan blades are made of fiberglass-reinforced plastics, which provide higher chemical and physical stability compared to aluminum blades. Due to their smooth surface, they cause less friction and minimize air resistance. These blades are manufactured using isophthalic resin and high-quality fibers.

- Fan Arm: This part connects the blades to the hub and is made of carbon steel with galvanized coating.

- Fan Hub: Made of ductile cast iron with coupling design, allowing easy assembly of the blades.

- Bolts and Nuts: High-strength dry bolts and nuts are used in the production of the blades. It should be noted that in acidic and corrosive environments, stainless steel fasteners are also used.

Cooling Tower Inverter or Variable Speed Drive System

- By ordering the cubic cooling tower with an inverter system installed in the control panel, it is possible to adjust the fan and motor speed for precise control of the cooling tower outlet water temperature. (If the inverter system is ordered, a separate control panel must also be provided for the tower.)

- The inverter frequency adjustment is controlled by a sensor that operates within a defined temperature range. Inverter operation is based on frequency variation, keeping the motor power constant. When the outlet water temperature is not very critical, thermostats are used instead for on/off control of the motor.

Estimated Space Required for Installing an 80-Ton Cooling Tower

All cooling towers must be installed outdoors in direct contact with fresh airflow. Sufficient open and unobstructed space should always be available around the cooling tower to ensure easy access to fresh air.

The hot discharge air from the tower must be exhausted in a way that prevents it from recirculating into the tower, as this would raise the wet bulb temperature and keep the outlet water temperature high.

In general, for towers up to 2.5 meters in height, 0.1 m² per refrigeration ton (for building applications) is required for every 50 m² of net building area. For towers over 2.5 meters in height, 0.12 m² per ton is needed for every 50 m² of net building area.

Therefore, the required installation space for the DamaTajhiz cubic cooling tower 80 TR, model DTC-CO 80, is approximately 9.6 m².

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

Tips for Transportation and Installation of an 80 Tons Cooling Tower

- If the diameter of the purchased cubic fiberglass cooling tower exceeds 250 cm, it is recommended to transport the tower in separate parts to prevent damage during transportation. Final assembly of towers larger than 250 cm in diameter will be carried out at the project site with additional costs.

- If it is not possible to transport the cooling tower in one piece to the site or rooftop, please order the tower in a disassembled form at the time of purchase.

- All transportation costs and possible reassembly costs of the cooling tower at the installation site are the buyer’s responsibility.

Order an 80-Ton Cooling Tower with DamaTajhiz Warranty

- The DamaTajhiz cubic fiberglass cooling tower 80 TR comes with a 15-month golden warranty and 10 years of after-sales service.

- At DamaTajhiz reference and specialized center, technical specifications and guaranteed prices for buying cooling towers with golden warranty are provided to ensure an optimal and smart purchase experience.

- To view and check warranty and technical specifications of various industrial and residential cubic fiberglass cooling towers, click on the “Technical Specifications” tab on each product page.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, don't hesitate to contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.