Air Cooled Chiller

Air-Cooled Chillers are considered the most critical component of central HVAC systems in hot and humid climates. Below, we provide technical specifications, capacity estimation, technical requirements, and guidelines for selecting and ordering air-cooled chillers, intended as a comprehensive reference.

Expert Guide to Choosing Air-Cooled Chillers and Price List

Air-cooled chillers are utilized in air conditioning systems to provide cold water, typically between 7 and 12 degrees Celsius, or in industrial refrigeration systems through the condensation refrigeration cycle. Air-cooled chillers are used as the beating heart of the building's cooling system, where water cooling towers and water-cooled chillers are not usable because of high relative humidity (RH).

The mechanism of the air-cooled chillers (usually installed in open spaces such as the roof of the building) is based on the condensation refrigeration cycle, similar to the water-cooled chillers.

The Main Parts of an Air-Cooled Chiller

Air-cooled chillers usually contain four main parts, which are as follows:

- Compressor

- Condenser

- Evaporator

- Expansion valve

- Control Circuit

- Refrigerant

The operation and role of each of these components in the air-cooled chiller are fully explained in the following sections.

Review, Selection, and Pricing of HVAC Equipment

Capacity Calculation of an Air-Cooled Chiller

Before we start, let us inform you that the "nominal capacity" and the "actual capacity" of an air-cooled chiller are the most important things to keep in mind when choosing the Air-cooled chiller, considering the average temperature (outdoor temperature) of the hottest days in summer of the operating area.

Also, consider the sufficient heat exchanger levels in "the condenser" and "evaporator", length, diameter, and the number of tubes used in the condenser as one of the significant factors in the performance of the actual capacity of an air-cooled chiller.

To calculate the required air chiller capacity (phase 1 electricity) for residential and office buildings in cities like Tehran, Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul, consider 1 ton of refrigeration (12000 BTU) capacity for every 30 square meters of usable building infrastructure.

In hot and humid climates such as Ahvaz, Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha, an additional 20 to 30% cooling capacity is required for air-cooled chillers, according to the project facility expert's calculations and HVAC calculation software.

Also, before finalizing the capacity calculation of the chiller, contact the experts of DamaTajhiz HVAC Group to choose the right capacity of the required device for the project. Our experts are always ready to answer you.

Factors to Consider When Choosing Air-Cooled Chiller Capacity

Consider the volume of cold water needed and the reliability coefficients necessary for efficient chiller operation. Generally, facility experts determine the air-cooled chiller capacity required for each project by calculating the total cooling load capacity and considering various factors. Factors such as:

- Geographical conditions

- Ambient temperature and altitude from sea level

- Relative air humidity

- Building usage (interior temperature)

- Buildings materials

- Facade design

- Building orientation relative to the sun

- Number of floors

- The building's substructure level

- The number of occupants and the electrical equipment inside the building

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

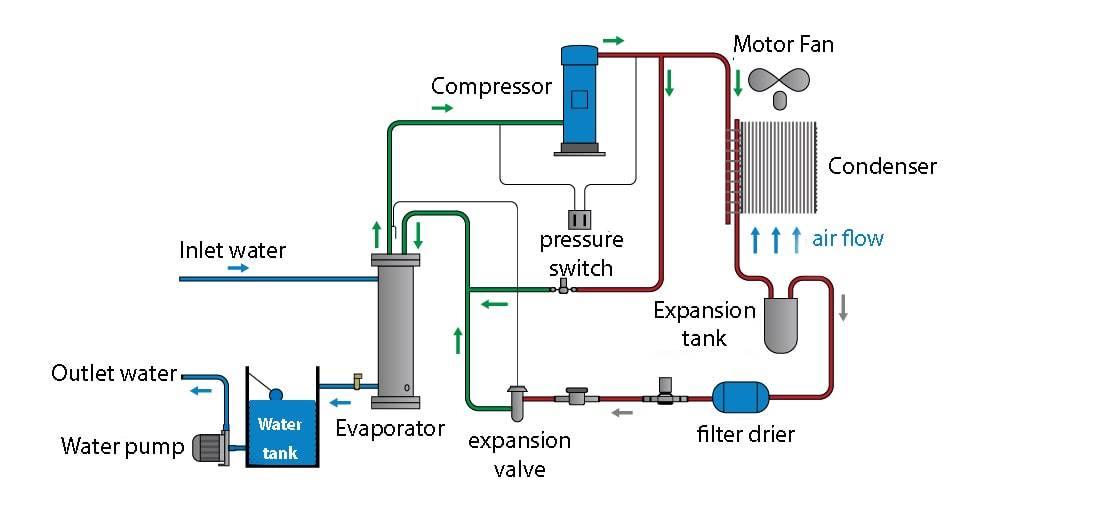

Refrigeration Cycle in Air-Cooled Chillers Explained

First, condensed gas with high pressure and temperature enters the condenser, cooled by the ambient air (forced-blown air of the fan), and turns into a liquid at the lower section of the condenser.

Then, this liquid is cooled by passing through the expansion valve or capillary tube, resulting in a sudden drop in liquid pressure. This allows the refrigerant liquid to absorb the heat of the water inside the evaporator after entering the evaporator coil. As a result, the refrigerant liquid absorbs heat from the water and then evaporates.

As a result, the water in the refrigeration system is cooled inside the evaporator. Then, it is transferred by the circulator pump system to the fan coil units and air conditioners to create cool air in the selected location. After the compressor's suction, due to the evaporation of the refrigerant, it moves toward the compressor in the evaporator, and the cycle repeats.

Air-Cooled Chiller Circuit Information

The operating temperature of a chiller in air conditioning systems refers to the temperature of the chilled water exiting the evaporator. This temperature should not fall below 7 degrees Celsius (44.6 degrees Fahrenheit).

Also, the temperature of the water returning to the evaporator should be approximately 5 degrees Celsius (9 degrees Fahrenheit) warmer than the water coming out of the evaporator. Additionally, it is crucial to remember that the standard set temperature for the antifreeze thermostat is typically 4 degrees Celsius (39.2 degrees Fahrenheit).

Air-Cooled Chiller Multi-Stage Thermostat and the Unloader

Using a 3-stage or 4-stage thermostat based on the type of chiller, the number of compressors, the number of air chiller circuits, or even the unloader system that is installed on the output water of the evaporator can increase the performance according to the set temperatures on the gradual thermostat.

Installing the unloader system in the compressor of the air-cooled chiller can save and reduce electricity consumption by reducing the refrigeration load. The unloader mechanism is used to reduce the pressure load during start-up and the capacity control during use in a way that is completely proportional to the amount of refrigeration required, which increases the life of the device and its efficiency compared to other systems. Moreover, significantly reduces the cost of electricity, maintenance, and repair.

Unloading the compressor in proportion to reducing the system load reduces the input power to the compressor. It reduces the stress on the engine and compressor, which is caused by the number of times the device is turned on and off.

4 Technical Information About Air-Cooled Chillers

There is much technical information to keep in mind when choosing an air-cooled chiller, but here are 4 of the most important ones:

- Free cooling in air-cooled chillers

- Superheat refrigerant in the suction line of the compression chiller

- Subcool in Subcool compression chiller condenser

- Pump down compression chiller Pump Down

Air-Cooled Chiller Compressor Types

When choosing an air-cooled chiller or any other chiller, it is essential to consider not only the type of compressor (screw, scroll, reciprocating, etc.) but also the number, capacity, and brand, as these are some of the main components of chillers.

Compressors used in air-cooled chillers have several types based on refrigerant gas compression mechanisms. These compressors can be categorized into the following groups:

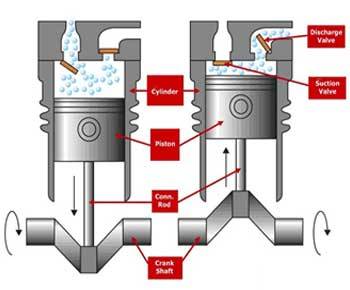

- Reciprocating or piston compressors (reciprocating)

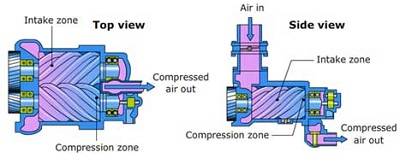

- Screw compressors (Screw)

- Spiral compressors (Scroll)

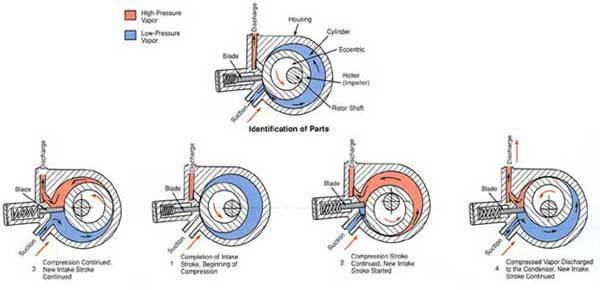

- Rotary compressors (Rotary)

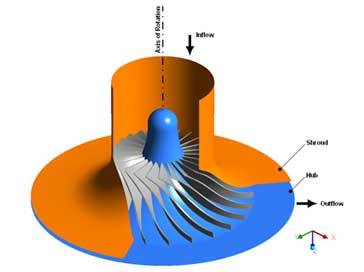

- Centrifugal compressors

The operating principle of the first four compressors, "positive displacement", significantly differs from centrifugal (dynamic) compressors.

In "positive displacement" compressors, a certain volume of gas is constantly reduced by the piston, spiral, or rotation, and as the gas volume decreases, the vapor pressure increases. In centrifugal compressors, the refrigerant gas is compressed due to acceleration by the rotating propeller, and its pressure increases as the speed decreases in a diffuser.

Note: Centrifugal compressors are used in very high capacities.

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

Types of Compressors Based on the Housing & the Electric Motor

In terms of the connection between the compressor housing and the electric motor, compressors are divided into the following three categories:

- Closed-Type Compressor (Hermetic): In closed compressors, the electric motor and compressor housing share a single shell, making repairs impossible in case of damage. These compressors typically have a smaller capacity.

- Open-type compressor: Open-type compressors have separate compressor housings and electromotor components connected by a coupling, and these compressors are designed for high-capacity applications.

- Semi-Hermetic compressor: Semi-hermetic compressors feature a two-part shell, with the motors and electro-motors in separate compartments. The engine and compressor parts are completely visible, and these compressors have a higher capacity than closed compressors.

Buying an Air-Cooled Chiller

Before discussing the price of the air-cooled chillers and accompanying equipment like fan coils, it's essential to understand the installation site's climate and weather conditions, the cooling capacity, maximum cold water flow, and required water pressure.

When buying an air-cooled chiller, it is essential to understand the installation site's climate and weather conditions, the cooling capacity, maximum cold water flow, and required water pressure.

The DamaTajhiz HVAC website provides technical information for numerous air-cooled chiller models from reputed brands, with their main guarantee, allowing you to make informed and smart buying decisions.

Air Cooled Chillers Prices

There are various useful factors concerning the price of both buying and installing an air-cooled chiller; the most important one is the type of capacity and technical specifications, the type and brand of the selected chiller equipment.

The installation cost of an air-cooled chiller differs based on the project's capacity, specific conditions, and workers' expenses.

All the air-cooled chillers presented on the website of DamaTajhiz HVAC Group have product IDs and reasonable prices, and the discounts are already included.

Air-Cooled Chiller Condenser Overview

A condenser is a heat exchanger that transfers heat from the refrigerant gas to the air. Condensers used in air-cooled chillers are cooled down via air. The device condenser comprises copper tubes (for refrigerant liquid flow) and aluminum fins (for air passage and heat transfer).

Comparison table of how air-cooled and water-cooled condensers work

| Air-cooled condenser | Cooled water condenser |

|---|---|

| More power consumption | Less power consumption |

| No need to use water | High water consumption |

| Suitable in most climates and weather conditions | Restrictions in less climatic conditions (hot and dry) |

| Higher starting price | Lower initial price |

| No need for water pumps | The need for cooling tower water circulation pumps |

| It has a lower performance factor | Higher coefficient of performance (higher COP) |

| Installing the device outdoors | Installation of the device in the central engine room |

| Simple maintenance conditions (no need for acid washing and sedimentation) | Complex maintenance conditions (requires sedimentation and acid washing) |

| Larger dimensions | Smaller dimensions |

Air-cooled Chiller Condenser Types

Typically, there are three types of condensers:

- Air-Cooled Condenser: In air-cooled condensers, the air is used as a cooling agent and for refrigerant distillation.

- Water-Cooled Condenser (double-tube, shell, and coil, shell and tube condensers): In water-cooled condensers, water is used as a cooling agent and refrigerant distillation instead of air.

- Evaporative Condenser: In evaporative condensers, both air and water are used. Although in evaporative condensers, the temperature of the passing air increases a little, the distillation of the refrigerant is mainly caused by the evaporation of the water sprayed on the condenser. The result from the evaporation, which is mainly used in the first type of air-cooled chiller, is to increase the intensity of the evaporation by removing the water vapor

Airflow in air-cooled condensers can be done in the following two ways: 1. Natural, without ventilation fans, such as refrigerators and freezers. 2. Airflow by fan or ventilation (forced airflow)

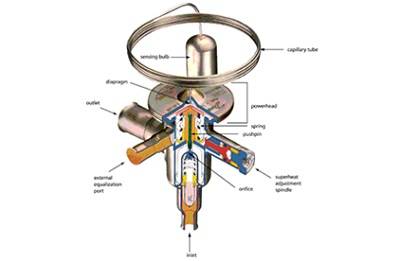

Expansion Valve in the Refrigeration Cycle of the Air-Cooled Chiller

The expansion valve in all air-cooled chillers causes a sudden drop in pressure in the path of the refrigerant gas passing to the evaporator, causing the refrigerant gas to change from hot to cold.

The expansion valve in an air-cooled chiller can be designed as mechanical, thermostatic, or electronic. Electronic expansion valves are used in high-capacity chillers to provide enhanced and precise management and control of the output water temperature.

Types of Evaporators in Air-Cooled Chillers

The expansion valve in all air-cooled chillers causes a sudden drop in pressure in the path of the refrigerant passing to the evaporator, causing the refrigerant to change from hot liquid to cold refrigerant. The expansion valve in a chiller can be designed as mechanical, thermostatic, or electronic. Electronic expansion valves are utilized in high-capacity chillers to provide enhanced and precise management and control of the outlet water temperature.

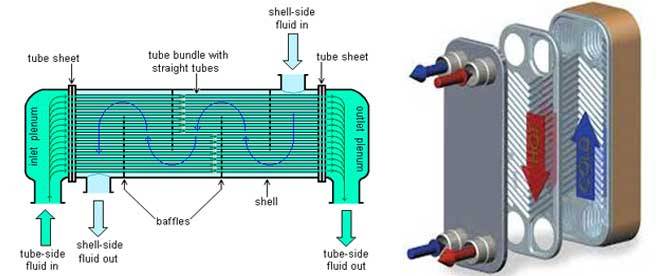

Shell and Tube evaporator

In this type of evaporator, parallel horizontal tubes are embedded in a very strong steel shell, where the liquid fluid (refrigerant) inside the tubes and the water circulating in the air conditioning system or industrial cycle around the tube (inside the shell). With the exchange of heat between the liquid fluid inside the pipes and the water inside the shell, the water temperature decreases and cools, and on the other hand, the liquid fluid changes its phase and turns into a gas by absorbing heat from the water.

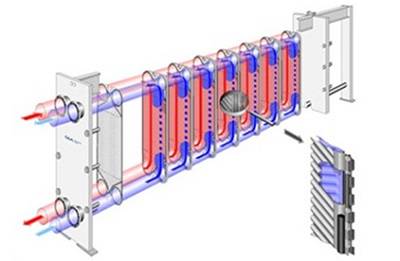

Plate evaporator

These evaporators consist of metal plates, which are placed together, and two fluids without physical contact with each other are created from a distance and pass between these plates, which are completely sealed to each other, and exchange heat with each other. These evaporators are used in special applications and conditions.

Evaporator with fan or DX

In this type of evaporator, the refrigerant passes through winding pipes, and the air flows around the pipes by a fan. For this reason, it is called an air evaporator with a fan. The fluid inside the tube cools the air volume by taking heat from the air passing through the tubes and directing it to the desired location.

DamaTajhiz; The Best Prices and Brands of Ventilation, Heating, and Building Facilities Equipment (Since 2004)

Manufacturing Order & Guarantee of Air-Cooled Chillers

At the DamaTajhiz HVAC Group, we offer various air-cooled chillers from various brands with main guarantees. Our selection is designed to meet the needs of professionals and engineers, providing an easy and suitable buying experience. As a leading supplier of air-cooled chillers in the Middle East region, you can easily place your order for any country within the area.

Our sales experts ensure the main product guarantee and competitive pricing, giving you peace of mind throughout the buying.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

1Ton of Ref.=12000 B.T.U. = 3.516 Kw

1Gal. (am.)= 3.785 Lit

1K.Cal = 4 B.T.U

C = 1.8 ˚F

˚F= 9/5 ˚C + 32

Kw X 860 = K.Cal

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.