Thickness Gauge

As you know, the main prerequisite for doing any work is to have proper information about that subject. In order to choose, review the prices, buy and know more about thickness gauges, the following contents are included so that you, dear visitors of the specialized website of Damatajhiz, can use these information to choose and bulk buy thickness measuring instruments from Bentech, Yoase, Elkometer, Yuxa, Phoenix, Wintech, Deflesco, etc. brands.

What is a thickness gauge?

The thickness gauge is analyzer equipment for measuring the thickness of different parts, which is used in different fields, especially in quality control. Calipers are among mechanical examples of this tool. The advantage of this device over calipers is that we need two-way access to the part to use a tool like calipers. Still, the thickness gauge is a digital device that can measure the thickness of many objects and parts using technology and in different ways. It can be determined with high accuracy by accessing one of their levels without destroying it.

Like all other equipment, the thickness gauge has different types, which are offered in various models based on the options required by the user and to optimize the purchase price. Its more basic types can measure and display the thickness of parts. At the same time, more advanced models have memory and can display more accurate statistical information such as the average, standard deviation, and minimum and maximum thickness to the user.

Thickness gauges can be divided based on the technology used in their design and construction. 3 of the most important methods are:

- Ultrasonic thickness gauge

- Magnetic thickness gauge

- Eddy's current thickness gauge

Magnetic and eddy current thickness gauges are also called coating thickness gauges. In the following, we will examine each of these thickness gauges and their method of operation.

Ultrasonic thickness gauge

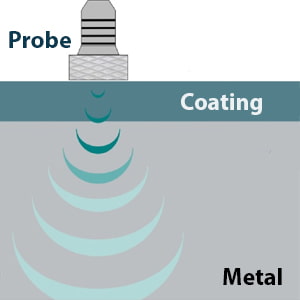

Measuring the thickness of objects using ultrasonic technology and tools (UTM) is a method for non-destructive measurement of the local thickness of a solid element (usually metals). This tool measures the thickness of the piece based on the time it takes for the ultrasonic wave to propagate and return to the surface of the probe.

The ultrasonic wave speed in this measurement is calculated and assumed to be constant according to the type of alloy. Of course, other factors, including temperature, influence this speed, which is usually ignored. By monitoring the ultrasonic wave, the thickness of the part is calculated using the following formula:

In this formula, the parameters are defined as

- L: the local thickness of the device

- C: constant speed of the ultrasonic wave in part according to its material

- t: the round trip time of the ultrasonic wave

This formula divides the distance traveled by the ultrasonic wave by 2. The reason is that in measuring the thickness using the ultrasonic method, we only have access to one surface (in fact, it is unnecessary to access both sides of the part in this method). The ultrasonic wave travels through the thickness of the desired part at a constant speed; then, after hitting the opposite face, it reflects and travels the same path again. As a result, by dividing the path traveled by the ultrasonic wave by 2, the thickness is calculated.

The propagation of the ultrasonic wave and the measurement and recording of its return time is done by the equipment and sensors placed in the thickness gauge probe. Therefore, the probe is one of the essential parts of the thickness gauge device.

Advantages of ultrasonic thickness gauge

Ultrasonic thickness gauge has many advantages, the most important of which are:

- No need for destruction

- No need for two-way access to the sample piece

- The ability to measure the thickness of objects from the coating without the need to remove it

- Acceptable accuracy (0.1 mm or less)

- Easy to use

- Relatively low price

Disadvantages of ultrasonic thickness gauge

In addition to these advantages, the ultrasonic thickness gauge also has disadvantages, among which are:

- The need for calibration to measure the thickness of different parts with different alloys and metals

- It needs to be in good contact with the part for high measurement accuracy.

Therefore, the thickness of a piece can be measured using an ultrasonic gauge.

Now you may have another question in your mind. How do you measure the thickness of paint and coating parts (for example, car paint)?

coating thickness gauge (magnetic and eddy current)

It is possible in two ways:

- Destructive thickness measurement: cut down to the underlying layer using a cutter.

- Non-destructive coating thickness measurement: using techniques that do not damage the coating or layer, such as magnetic and eddy current thickness measurement methods.

Non-destructive coating thickness measurements can be performed on magnetic or non-magnetic metal surfaces such as stainless steel or aluminum. Digital coating thickness gauges are ideal for measuring coating thickness on metal layers. Electromagnetic induction is used for non-magnetic coatings on ferrous layers such as steel, while the eddy current principle is used for non-conductive coatings on non-ferrous metal layers.

Therefore, magnetic thickness gauge and eddy current are analyzers used to measure the coating thickness of parts. Choosing one of them as a measuring tool depends on the material of the desired part. The magnetic method is usually used to measure the thickness of paint and coating magnetic, iron, and steel parts, such as automobiles, with an insulating coating. The eddy current method is used for objects with electrical and non-magnetic conductive materials, such as non-magnetic stainless steel and aluminum. It works.

Note that nowadays, most thickness-measuring devices are equipped with thickness measurement tools of both magnetic and vortex methods to have the ability to measure the thickness of the covering of objects with a broader range of diversity.

In the thickness gauge group of the DamaTajhiz reference site, information and prices of Bentec brand thickness gauges with original warranty are presented for your review and purchase, dear users and employers.

In addition to a valid business license from the heating and air-conditioning trade union, DamaTajhiz has an electronic trust symbol and has been operating its store site since 2013 in Tehran's head office.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.