flowmeter (flow gauge)

As you know, the main prerequisite for doing any work is to have proper information about that subject. Regarding selection, checking prices, buying and know more about flow meters, the contents are included below so that you, dear visitors of the specialized website of Damatajhiz, can use these tips to choose and buy water, air, gas and ultrasonic flowmeters from Rosemont, Endress Hauser, Medco, Krohne, etc. brands in bulk.

An Introduction to flowmeters

Flowmeter (flowmeter or flowmeter) is a fluid flow measurement tool with different techniques to measure the flow. To choose a suitable flowmeter and measure the flow correctly, one should pay attention to things such as the chemical and physical structure of the fluid (temperature, pressure, density, allowable pressure drop, viscosity, electrical conductivity, vapor pressure, maximum working temperature, etc.) and It is also necessary to have things like weather fluctuations, the correct direction of installation (to prevent the gravitational movement of liquids when passing through the flowmeter), the diameter and material of the pipes, the compatibility of the standards of pipe construction with the standards of the flowmeter, the amount of pressure tolerance in the flanges, are available. The location of the flowmeter installation (for possible repairs), the distance to the installation location of the control valves, the possibility of mechanical vibrations or the formation of a magnetic field near the flowmeter, the corrosiveness of the fluid, and the type of use (for example, in explosive environments) were considered. Join us in introducing and checking the performance of different types of flowmeters in the rest of this article (for wholesale purchase).

Types of flowmeters in terms of flow measurement technique

- Positive displacement flow meter

- Orifice Plate flow meter

- Turbine flow meter

- Rotameter flow meter

- Ultrasonic flow meter with Doppler phenomenon: Doppler

- Ultrasonic flowmeter (flow meter) with the transfer time method Ultrasonic: Transit Time, Time of Travel, Time of Flight

- Venturi flowmeter

- Magnetic or electromagnetic flow meter

- Vortex Shedder flow meter

- Flow meter (flow meter) for Weir and Flume Open channel

- Coriolis flow meter

- Thermal flow meter

- Pitot Tube flow meter

- Differential pressure flowmeter

Magnetic flow meter or electromagnetic Magnetic Flowmeter

An electromagnetic flowmeter measures fluid flow in electrically conductive liquids (such as drinking water and sewage water, alkaline substances, slurry, and acids). The magnetic flowmeter is primarily used in the water, food, and mineral industries.

When the metal rod moves inside the magnetic field, charged fluid particles pass through the magnetic field created by the coil, and an electric voltage is induced. The intensity of this voltage is proportional to the speed of the passing fluid and is used to measure the volume flow rate of the liquid.

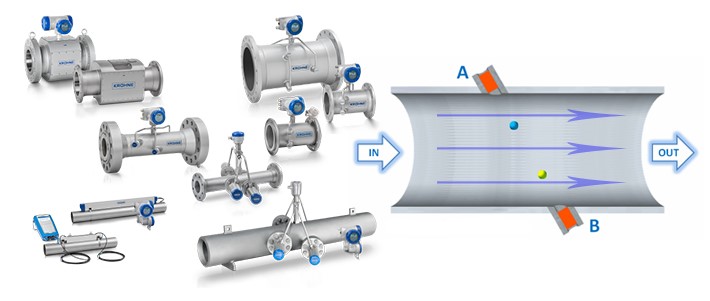

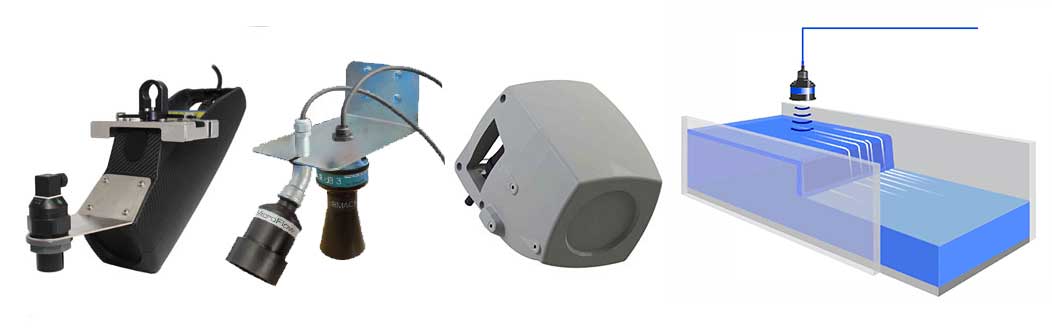

Ultrasonic Flowmeter

The ultrasonic flowmeter uses ultrasonic waves to measure the volumetric flow rate of many liquids and gases. The measurement accuracy in these flowmeters is low due to not considering pressure, temperature, viscosity, and electrical conductivity. There are two sensors in these sensors, which are placed outside and inside the flowmeter. The first sensor is suitable for corrosive fluids, and the second sensor is more accurate.

The operation of the ultrasonic flowmeter is such that each of the two sensors of this flowmeter act as both a transmitter and a receiver, the duration of the arrival of the ultrasonic waves from the transmitter to the receiver indicates the flow rate of the fluid inside the pipe.

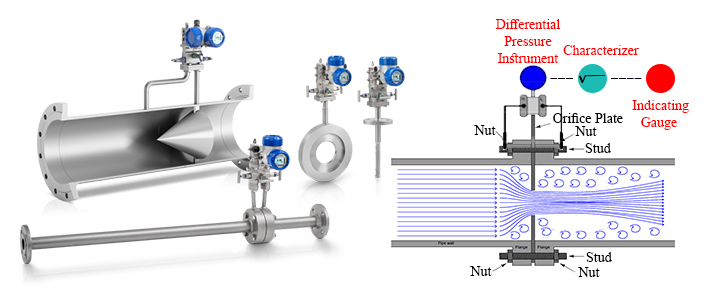

Differential Pressure Flow meter (Orifice Plate Flowmeter)

The differential pressure flowmeter calculates the fluid flow by measuring the pressure drop created in the pipe section. The function is such that a limiting factor (orifice plate or venturi tube) is placed on the path of the fluid, and this factor causes a pressure drop in the juice. The greater the flow rate, the greater the pressure drop, and the pressure upstream and downstream of this limiting factor will be proportional to the second power.

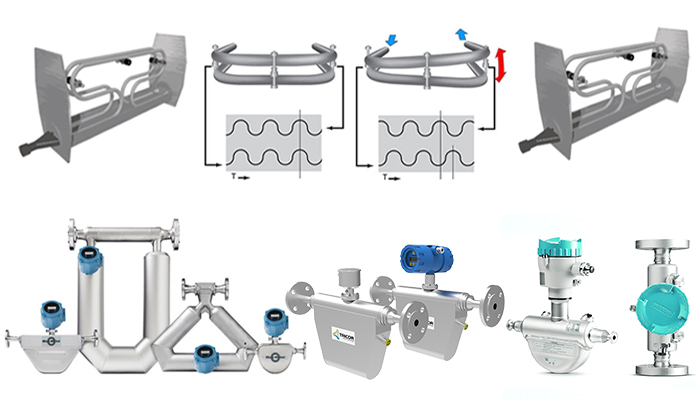

Coriolis Flowmeter

The Coriolis flowmeter has two measuring tubes that are oscillated by an exciter. When the flow is established in the pipe due to inertia, a rotational motion is added to the oscillation. The fluctuation change caused by the pressure difference is measured by two sensors used in the flowmeter, and this phase difference is directly proportional to the mass flow rate of the fluid. Fluid density is also measured by measuring the frequency that oscillates through the tube. This flowmeter measures mass density directly and is used in cases where density and temperature are variable.

Coriolis flowmeter is suitable for measuring most liquids, including crude oil and chemical cleaners, vegetable oils, sauces, etc., and can simultaneously measure mass flow rate and density.

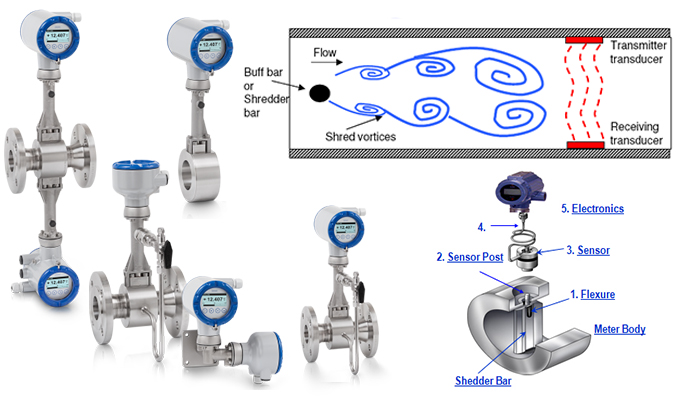

Vortex Flowmeter

A vortex flowmeter measures the volume flow of gases, vapours, and liquids. Thus, when an obstacle is placed on the path of the flow, eddies are formed, and the frequency of the formation of these eddies is directly related to the size and shape of the obstacle. Vortices are formed under the barrier when the fluid velocity exceeds a specific limit. After separating the vortices, the pressure on the surface of the barrier fluctuates between positive and negative values. After detecting any fluctuations caused by fluid pressure (detection by capacitive or piezoelectric sensors), the sensor issues an output signal whose frequency is equal to the frequency of the vortex. Using the output signal, you can calculate the fluid flow rate.

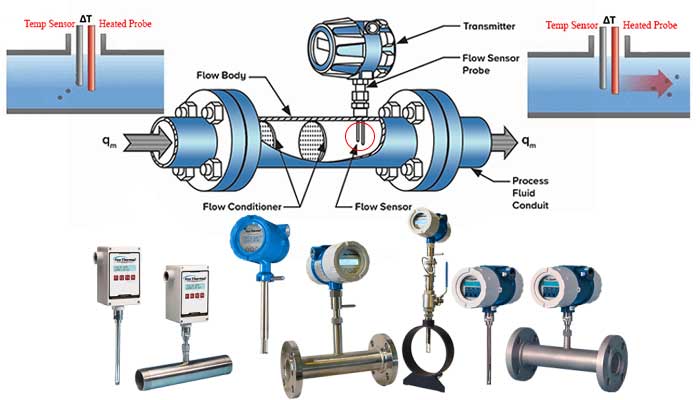

Thermal Flowmeter

Thermal flowmeters are used to measure mass flow to control and monitor the consumption of gases such as carbon dioxide, compressed air, and natural gas, and leak detection. In cases where a two-phase two-gas mixture is used in the flowmeter, it causes corrosion of the temperature sensor and measurement error. The thermal flowmeter has two temperature sensors, one of which measures the temperature of the fluid as a reference temperature, and the other is heated and has a fixed temperature difference from the first sensor. As the fluid passes through the tube, the temperature sensor of the second sensor decreases and cools. Now, they use the electric current required to maintain a constant temperature difference between two sensors as a criterion for measuring the mass flow rate. This measurement method in the flowmeter is also called hot wire measurement.

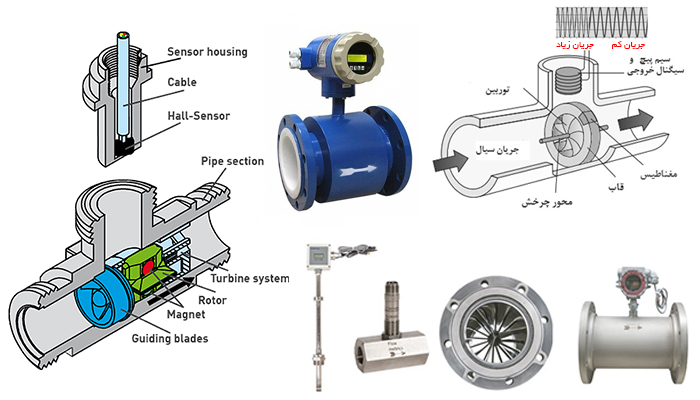

Turbine Flowmeter

The turbine flowmeter consists of a turbine with specific blades and a sensor (for example, a proximity switch) that generates pulses with each revolution of the turbine due to the passage of current and flow; the difference between these pulses with specific pulses is that the device is calibrated according to to do, the range of the flowmeter is obtained.

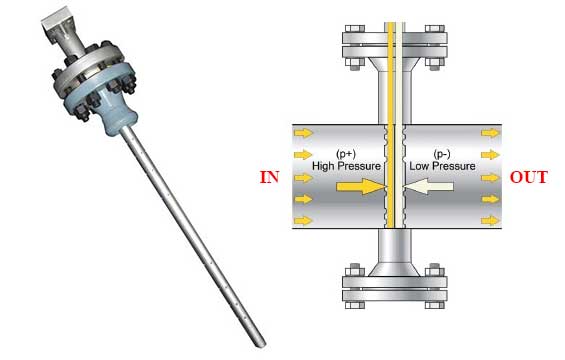

Pitot Tube Flowmeter

The pitot flowmeter uses the pitot tube method to measure the flow of gaseous fluids, especially air, in a low range. The pitot tube method says that the airflow in one end of the tube makes the pressure become lower than the pressure of the other part of tube.

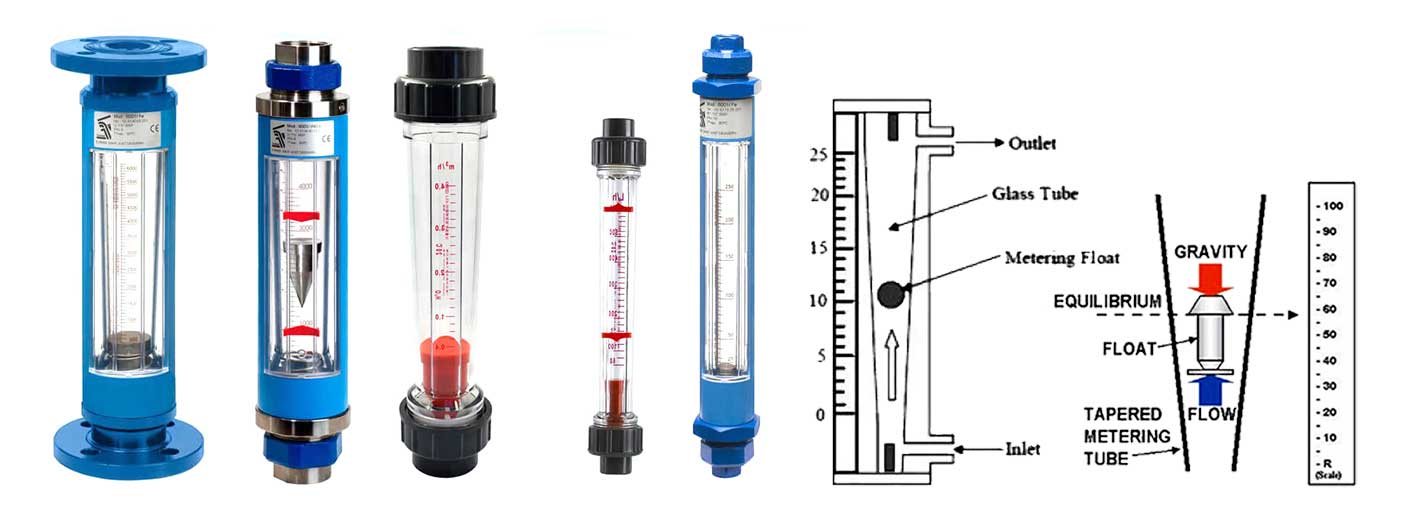

Rotameter Flowmeter

In the rotameric flowmeter, the fluid enters the conical tube vertically and from top to bottom. A float with a volumetric mass more significant than the volumetric mass of the fluid is located inside the tube. As the flow rate increases, the float will move upwards, and the location of the fluid will indicate the fluid flow rate.

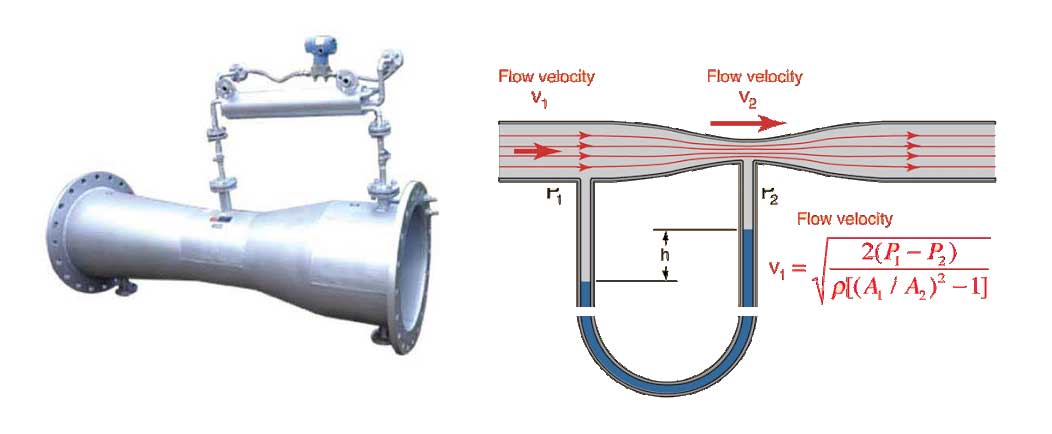

Venturi Flowmeter

Like the orifice flowmeter, the fluid flow is obtained by measuring the pressure difference in the venturi flowmeter, with the difference that in the venturi flowmeter, the initial pressure and the minimum pressure of the venturi tube throat are measured. The fluid flow rate is calculated based on the pressure drop in the venturi tube throat caused by the flow rate of the passing fluid. These flowmeters are not suitable for measuring slurry fluids.

Positive Displacement Flowmeter

The positive displacement flowmeter is used to accurately and quantitatively measure fluids, especially fluids with high viscosity. The positive displacement flowmeter has different types, such as rotating disc, flowmeter, rib, piston, elliptical, and diaphragm models.

Open Channel Flowmeter

Flowmeters for open channels are non-contact flowmeters that can measure the flow rate of fluid passing through the channel with ultrasonic waves.

In the flowmeter (flowmeter) group of the reference site and temperature equipment store, information and prices of all flowmeters or flowmeters, including electromagnetic flowmeters, ultrasonic flowmeters, Coriolis flowmeters, rotameric flowmeters, etc., from the brands of Anders Hauser, Krone, Rosemont, etc. View for review and selection.

(Damatajhiz) in addition to a valid business license from the heating and air conditioning trade union, it has an electronic trust symbol and started operating its store site in 2013 in the head office of Tehran.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.