Regulator and balancer

As you know, the main prerequisite for doing any work is to have proper information about that subject. In order to choose, review the prices, buy and know more about all types of regulators and balancers, the following contents are included so that you, dear visitors of the specialized website of Damatajhiz, can use these information to choose and buy regulators and balancers for gas, liquefied gas, air and gas ratio control from Dongz, Setak, Madas, etc. brands in bulk.

A brief introduction & buying guide for types of regulators& balancers

The gas regulator is used to reduce the gas flow pressure and keep it constant. In case of a sudden change in the gas flow, the gas regulator controls the gas pressure at a certain level and brings it to the equilibrium level. The task of the regulators is to convert high pressure into lower and suitable pressure for the device and reduce the input and output pressure. Regulators are used in the gas inlet of gas-burning equipment, engine houses, office, industrial, hotels, hospitals, gas and oil industries, and mining industries. Note that industrial regulators are used in industry, and household regulators are used in domestic applications. Join us in introducing and reviewing the performance of various types of regulators and balancers in the rest of this article (for wholesale purchase).

The most critical points in choosing a gas regulator

When choosing the required gas regulator, check the following:

- The pressure of the incoming gas from the regional gas supply network (for example, the gas pressure is 2 pounds, 30 pounds, or 60 pounds)

- The required pressure of the exhaust gas

- The gas flow is required for building heating equipment based on the capacity of burners and heaters

- The diameter of the gas pipeline entering the building or any heating equipment

- Regulator connection type, rib or flange

- The desired gas regulator brand

The main parts of the gas regulator

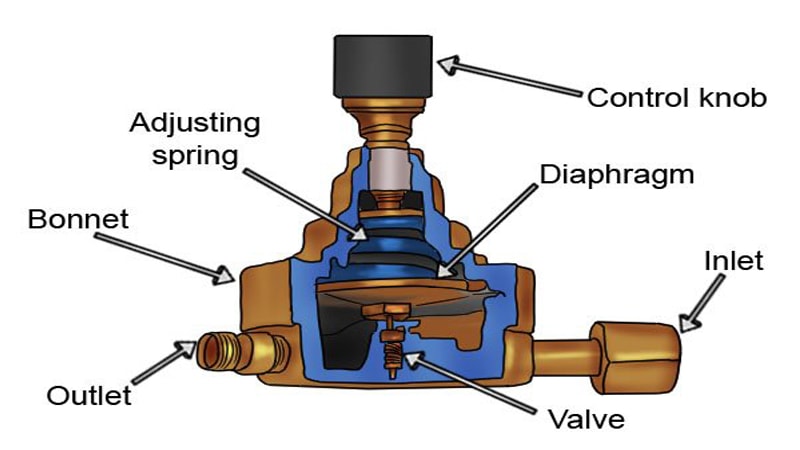

The natural gas regulator consists of five components: screw, spring, rod, diaphragm, and valve, and includes three parts as follows.

- The loading part consists of weight, spring, and gas pressure.

- The measuring part is the diaphragm.

- Distractor valve

In terms of construction, regulators are manufactured in spring loading and pilot-operated types.

The pilot is a spring that feeds on the input pressure and provides the output pressure according to the compression of its spring. This pressure is applied as steering pressure on the primary regulator.

Getting to know the components of a regulator

Body (Bonnet): The body material of the regulators is of great importance. When using laboratory and corrosive gases, the material of the pressure breaker body must be made of non-corrosive metal and resistant to possible chemical reactions and explosion-proof.

The body material of standard and industrial regulators is mostly brass. Still, laboratory regulators, due to having different types, can be made of brass with an anti-corrosive coating or stainless steel.

Control Knob: This part of the regulator is directly related to the user; in fact, the user gives the order to the gas pressure breaker to decrease or increase the gas pressure. Sometimes regulators are also equipped with pressure gauges, which help the user to make decisions. But there is no pressure gauge in standard regulators such as LPC capsule pressure breakers, and the output pressure adjustment is made visually.

Spring: The pressure-relief spring is placed between the diagram and the control handle, and the work of measuring and comparing the input and output pressure is done with the help of the spring's compression coefficient. The spring is responsible for adjusting the inlet and outlet valves of the pressure relief valve diagram.

Diaphragm: Diaphragm is made of a flexible metal or plastic shell and can block the flow of gas entering the pressure breaker and regulate the pressure of the outgoing gas.

Valve: During the rotation of the control handle of the regulator, the position of the diaphragm and the pressure-relief valve is changed, causing the pressure of the exhaust gas to decrease or increase.

Gas inlet: The gas inlet of the pressure breaker is directly connected to the gas tank or pipeline.

Outlet: The gas outlet is located on the other side of the pressure breaker and is usually opposite the gas inlet. The gas entering the pressure breaker leaves the outlet after the pressure decreases.

Types of gas regulators

Gas regulators can be used in a wide range of sizes and settings, but they all have the same function. Regulators are grouped according to the speed at which they deliver gas to the device, but they vary widely in shape and size.

In general, regulators are divided into two types: high-pressure regulators and low-pressure regulators. The high-pressure regulator can deal with gas entering the cylinder with a high force, which is usually used in the welding industry. The low-pressure regulator, which requires constant heat output, is widely used in gas-burning devices such as small domestic gas-burning steamers and gas stoves.

Natural gas regulator

The main feature of the natural gas regulator in home heating devices is its safety because it limits the flow of natural gas so that excess fuel does not enter homes.

A gas regulator consists of three elements: the loading mechanism, the sensing element, and the control device, all of which work to control the amount of gas pressure.

Propane gas regulator

Propane gas is used for indoor gas stoves and home heating, and since liquid gas is under pressure, that must be regulated by leaving the tanks because otherwise, it can cause the hose to rupture and cause an explosion. For this reason, a regulator is needed to adjust the gas pressure in propane systems.

The propane regulator is made of brass, and brass is spark resistant. Other metals, such as aluminum, are used to manufacture regulators because this metal is lightweight and resistant to sparks.

Casing gas regulator

A casing gas regulator is used to supply gas to petroleum fluid storage tanks and tanks.

Laboratory regulators

When using gases with high purity percentages, regulators with unique characteristics should be used. Also, the material of the pressure breaker body should not have a chemical reaction with the desired gas so that the pressure breaker or its components do not suffer from corrosion. Due to high sensitivity, special alloys such as Hastelloy are used in laboratory regulators.

Gas regulator capacity

One of the essential things in choosing regulators is their capacity, which is directly related to the inlet and outlet pressure, gas density, and the shape of the regulator body.

The ratio between input pressure (P1) and output pressure (P2) determines the regulator's output flow type. If the ratio P2< P1/2 indicates entirely critical flow, P2=P1/2 indicates critical flow, and P2> P1/2 indicates non-critical flow.

k is a constant coefficient and depends on the structure of the regulator and the type of fluid passing through it. The following formula is used to calculate the current in the regulators.

Q=K(P2(P1-P2))1/2

Regulator installation location

Regulators are installed and used in different places depending on the type of operation. The following will mention the most important places for installing regulators.

- Interline: These regulators are installed between pipelines.

- Tank and cylinder head: This regulator is installed on storage tanks and cylinders.

- Controller panel: This regulator controls gas pressure which can be designed manually, semi-automatically, or fully automatically.

- Consumption point: consumption point regulators are useful in gas pipelines such as household pipes.

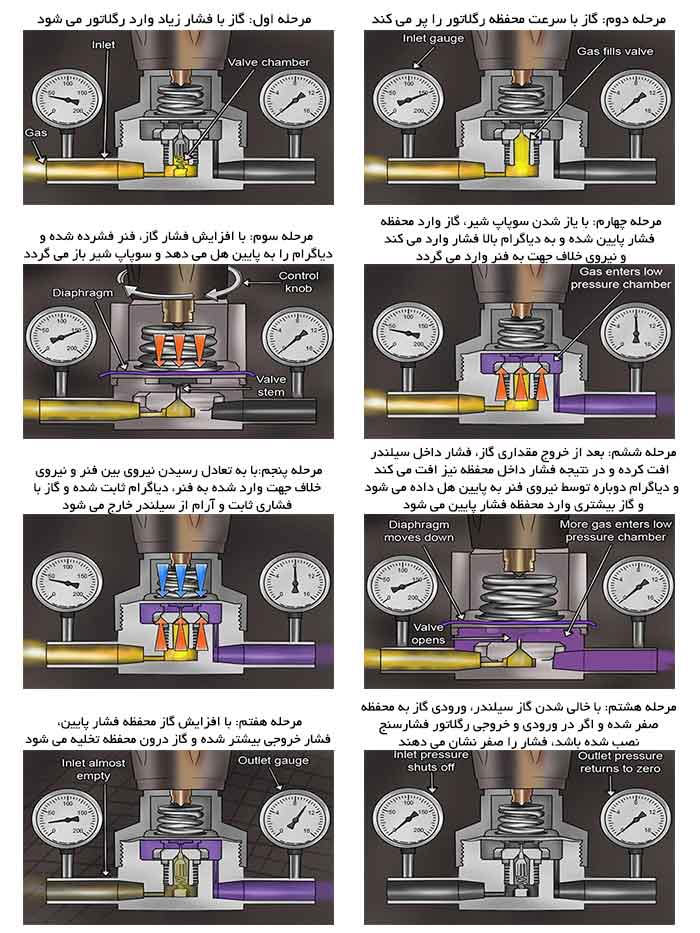

The general performance of regulators

What is a gas balancer

The balancer is a gas inlet pressure regulator whose task is to regulate the pressure of the gas piping circuit. The balancer regulates the maximum fluid flow with the minimum pressure drop. The working mechanism of the balancer is similar to the regulator. If the gas pressure entering the engine room where industrial burners from 800,000 kcal and above are installed about 2 pounds, it is necessary to install a balancer in the gas inlet pipe to each burner.

Balancers are responsible for balancing the pressure of the inlet gas, but if the pressure of the inlet gas to the engine room is 15 pounds or more, you must use a gas regulator whose function is to reduce the inlet gas to the burner. Note that it is necessary to install a gas balancer according to the size of the inlet pipe to prevent the failure of each burner's automatic solenoid valve diaphragm.

Information such as connection size, inlet and outlet pressure, and gas flow rate is required to choose gas balancers correctly. Balancers help the efficiency and correct use of the burner by accurately regulating the gas pressure passing through the burner.

You can get all kinds of gas regulators and balancers according to your needs and with the advice of our experts at the first opportunity on the Demathezis website.

In the regulator and balancer group, the reference site, and the Damatajhiz store, see the information and prices of all kinds of regulators and balancers from the brand's Dongs, Madas, etc., for review and selection.

In addition to a valid business license from the heating and air-conditioning trade union, Damatajhiz has an electronic trust symbol and has been operating its store site since 2013 in Tehran's head office.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.