Diesel pump

As you know, the main prerequisite for doing anything is to have proper information about that subject. In order to select, review the prices, buy, and learn more about diesel pumps, the following information is included so that you, dear visitors of the specialized website of DamaTajhiz, can use these tips to get enough information to choose and buy any burner diesel pump from Danfoss, Suntec, etc. brands in bulk.

Introduction and buying guide for burner diesel pump

What is a burner diesel pump?

Just as no human can live without a heart, a gas burner cannot function without a gas pump. This article will tell you what you need to know about the burner diesel pump and its functions. In the diesel burner system, fuel plays the role of blood in the body. For the system's proper functioning, it must be directed from the diesel tank to the nozzles and the diesel combustion chamber under constant and acceptable pressure. The burner diesel pump is designed and built to perform this task.

How?

We will discuss this issue further.

How does the burner diesel pump work

In liquid fuel heating systems, different types of pumps are used, and their primary purpose is to pump fuel into the combustion chamber. The design and operation method of the pump depends on the amount of fuel required and the desired pressure.

To create the required heat for heating, we need fuel, oxygen, and a spark (heat), and the burner is a device that combines these three basic things. The burner gathers the sides of the fire triangle together and thus provides the required heating of the building and the required hot water consumption.

As we said, the diesel pump must supply fuel to the combustion chamber and atomize the fuel in the burner nozzle so that this fuel forms the flame along with air and heat.

If we want to be more precise, for better contact of liquid fuel with air (oxygen) and as a result of its better ignition, it is necessary to drop this fuel into the combustion chamber. The task of spraying fuel in burners that work with liquid fuel is the responsibility of the nozzle, and the diesel pump pumps this fuel under high pressure toward the nozzle.

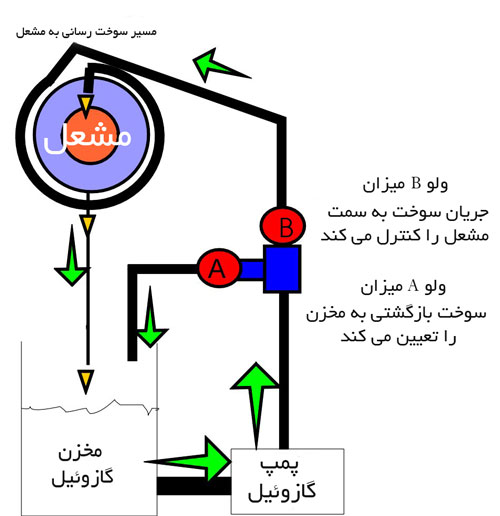

The diesel pump works by gears that rotate with motor-electric force. The output pressure of the diesel pump is positive, so it must be placed in the return path of the output diesel to prevent the pump from being damaged, remove the excess diesel from the output path, and return it to the pump inlet.

How the diesel pump works

Gear with a suction function pulls the required diesel from the nozzle, and after passing through the filter, it enters the valve compartment of the diesel pump. The function of this valve is to allow the passage of diesel required for the optimal performance of the nozzle. Finally, the pumped diesel, under the desired pressure, is directed to the inlet of the nozzle.

In installations that use two pipelines, excess diesel is pumped through the pipe to the return line, and in single-pipe systems, this excess diesel is returned to the intake section of the suction system. In this case, the return branch of excess diesel must be blocked entirely by a metal washer and fastener.

An essential point in the way of fuel for all diesel and diesel burners is installing and operating a diesel filter. If the diesel filter is not used, suspended or solid particles in the fuel will block the orifice of the nozzle, and the burner will misfire or choke!

Diesel pump cut-off system

As soon as the burner is turned off, the solenoid valve of the diesel pump, which is usually closed (NC), opens, and as a result, all the pumped diesel is directed to the return branch. In addition, the nozzle valve, usually open (NO), is immediately closed. In this way, the fuel flow cut-off system shows a speedy response to new conditions regardless of the speed of the pump motor. Note to adjust the flame and the heat created. As a result, a screw facing the diesel outlet is installed on the pump to adjust the output fuel flow rate.

There are two other screws on the pump body with the letters P and V next to them. Screw P is used to control the pump's output pressure, and screw V is used for ventilation. It should be noted that the burner diesel pump pressure should be at least 7 bar (bar), but in high-capacity burners, this diesel pressure is much higher and even up to 50 bar!

In the Mashal diesel pump group of the Damatajhiz website, information and prices of various Suntech diesel pumps with original warranty have been presented for your review and purchase, dear users and employers.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.