DAMATAJHIZ Booster pump

- Number of pumps: 2

- Maximum yield (MW / H): 14.4

- Maximum height (m): 50

- Ability to install the control system: Yes

1 year warranty

What is booster pump?

Booster pump is a combination between one electropump or a set of electropumps that are connected in parallel by required pipes and other related equipments on an appropriate chasis. It is used to provide required consumed water and supply water pressure in water-supply or firefighting systems especially in high-rise buildings.

1- Booster pumps are manufactured in two types of constant speed and variable speed based on their application, work load and number of pumps.

2- In water supply pumps inverter is used to prevent initial mechanical and electrical shock at startup. It causes smooth startup of electromotor and gradual increase of pump speed and power. When maximum power of pump is not sufficient in maximum water supply volume or when water pressure is not sufficient the second pump automatically enters the circuit.

3- In water supply booster pumps that work continuously PLC system is used to periodic start of pumps. The periodic start of pumps is called change over system.

Some advantages of constant speed booster pumps include

o Constant system pressure in changing amounts of water consumption

o No need to diaphragm tank which lead to reduction of occupied space in mechanical room

o No need to jockey pump

o Elimination of water hammer effect in piping network as a result of instantaneous electropump on and off

o Equivalence of amount of water pumped by booster pump and required consumed water

o Reduction in depreciation of moving parts of electropumps and consequently increase in lifetime of variable speed booster pump system

o decrease in maintenance cost in variable speed booster pumps

o up to 30 percent reduction in cost of consumed electricity as a result of applying inverter or gradual speed change system

4- In constant speed booster pumps one or more diaphragm tank by appropriate capacity are used. The admissible capacity of diaphragm tank for 15 times turning on and off any electropump is calculated by dividing capacity of one pump in liter per minute to number of pumps of booster pump.

Efficiency of diaphragm pump is usually 33 percent , so the nominal volume of the tank is 3 times bigger than its real volume.

5- In DAMATAJHIZ Co. all types of water-supply, firefighting and industrial booster pumps are manufactured and delivered after determination of number, model and type of project required electropump (LOWARA pump, PENTAX pump, EBARA pump, Grundfos, PUMP IRAN) by employer and confirmation of technical office or project consultant according to technical criteria and experience of experts.

6- All DAMATAJHIZ water supply and firefighting booster pumps are guaranteed for 18 months since production date or 12 month since installation date.

Common firefighting booster pumps of DAMATAJHIZ:

DAMATAJHIZ firefighting booster pumps are of booster pumps common in residential buildings.

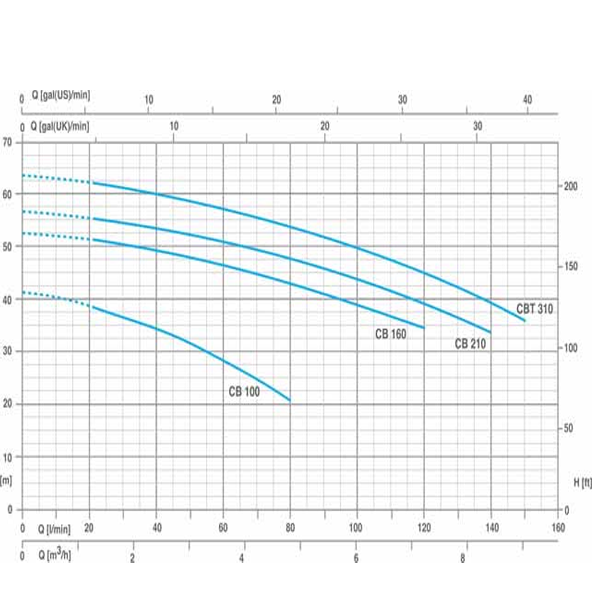

a) DAMATAJHIZ double line firefighting booster pump with PENTAX pump model CBT 310

With ZILMET 24 liters tank for 5-floor building with 5 fireboxes

b) DAMATAJHIZ double line firefighting booster pump with PENTAX pump model CBT 600

With ZILMET 24 liters tank for 8-floor building with 8 fireboxes

c) DAMATAJHIZ double line firefighting booster pump with PUMPIRAN pump model 250~32

With ZILMET 24 liters tank for 12-floor building with 12 fireboxes

d) DAMATAJHIZ double line firefighting booster pump with PUMPIRAN pump model 250~32

With ZILMET 24 liters tank for 14-floor building with 14 fireboxes

e) DAMATAJHIZ double line firefighting booster pump model 250~40 with PUMPIRAN pump model 250~40

With ZILMET 24 liters tank for 15-floor building with 15 fireboxes

Description of DAMATAJHIZ pumps

- All provided electropumps have electromotors with speed of 2900rpm.

- All DAMATAJHIZ booster pumps are equipped with 3-phase electro motors.

- All booster pumps have CIM valves made in Italy (original) and Yourk check valve made in Italy (original). They contain DANFOS pressure switches (KP1) keys as number as pumps, C10 manometer and HYUNDAI electrical panel made in Korea (original). These are warranted for two years.

- Other parts of DAMATAJHIZ booster pumps include:

- Waterproof electro-steel sheet with thickness of 1.5mm with all related equipment

- Pump is placed on chassis and chassis is placed on the main frame.

In DAMATAJHIZ firefighting booster pumps, black collectors with hygienic color cover (that are allowded in water supply applications) are used.

7- Common DAMATAJHIZ water supply booster pumps: DAMATAJHIZ water supply booster pumps are used in offices, hotels, hospitals and military sites in addition to residential buildings.

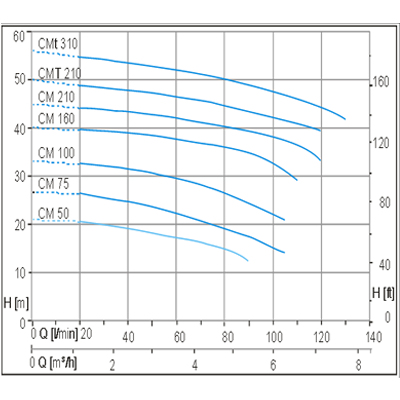

a) DAMATAJHIZ water supply booster pump with PENTAX pump model CAM 100

For buildings with up to 4 single unit floors and average area of 90 m2

b) DAMATAJHIZ water supply booster pump with PENTAX pump model CBT160

For buildings with up to 4 floors and 8 units on each floor, average area of 150 m2 and two bathrooms.

And also for buildings with up to 6 floors and 6 units on each floor, average area of 150 m2 and two bathrooms.

c) DAMATAJHIZ water supply booster pump with PENTAX pump model CBT210

For buildings with up to 6 floors and 2 units on each floor, average area of 120-150 m2 and two bathrooms.

d) DAMATAJHIZ water supply booster pump with PENTAX pump model CBT310

For buildings with up to 8 floors and 2 units on each floor, average area of 140 m2 and two bathrooms.

And also for buildings with up to 10 floors and 2 units on each floor, average area of 90 m2 and two bathrooms.

e) DAMATAJHIZ water supply booster pump with PENTAX pump model U5200-7

For buildings with up to 10 single unit floors, average area of 120-160 m2 and two bathrooms.

And also for buildings with up to 6 floors and 3 units on each floor, average area of 80 m2

f) DAMATAJHIZ water supply booster pump with PENTAX pump model CBT600

For buildings with up to 8 floors and 4 units on each floor, average area of 120-140 m2 and two bathrooms.

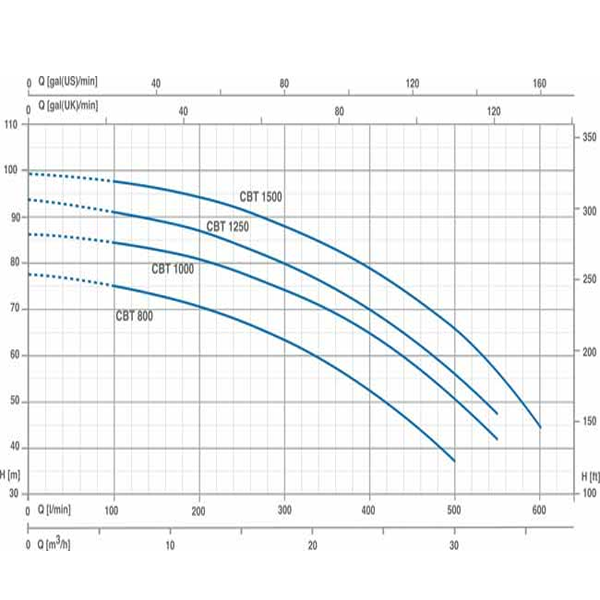

g) DAMATAJHIZ water supply booster pump with PENTAX pump model CBT800

For buildings with up to 8 floors and 2 units on each floor, average area of 120 m2 and two bathrooms.

h) DAMATAJHIZ water supply booster pump with PENTAX pump model CBT1000

For buildings with up to 15 floors and 60 units, average area of 70-140 m2 and two bathrooms.

i) DAMATAJHIZ water supply booster pump with PUMPIRAN pump model 32~250

For buildings with up to 7 floors and 60 units, average area of 80-120 m2 and two bathrooms.

j) DAMATAJHIZ water supply booster pump with PUMPIRAN pump model 40~250

For buildings with up to 8 floors and 80 units, average area of 70-140 m2 and two bathrooms.

Press on “Price and Technical Specification” on top of page to get information about all types of DAMATAJHIZ water supply and firefighting booster pumps.

Calculation of pressure (head) and discharge (water mass flow) of booster pumps:

Table for calculation of head or pressure of water supply booster pumps (adopted from manual of Grundfos)

To determine booster pump pressure , first find the building's height in the left column and then move horizontally to find minimum booster pump's pressure at cross point with the column (building area of each floor)

For example minimum booster pump pressure for a building with height of 50m and 400m2 building area on each floor is 7.44atm.

8- Table of calculation of discharge or water supply of booster pumps (adopted from manual of Grundfos)

It should be noted that U.Sgpm) 4.4 = (m3/h)

To determine maximum water supply of booster pump in a residential building first find number of residential units in the left column and then move horizontally to find booster pump water supply at cross point with column of single bathroom units (units with two bathrooms)

For example water supply in a residential building with two bathrooms is 18 m3/h or 300 lit/min.

To determine maximum water supply of booster pump in offices, hotels and hospitals first find number of people in the building in the right column and then move horizontally to find booster pump water supply on cross point with related column (hospital, hotel or office).

For example capacity of water supply booster pump in a hospital with 1000 beds is 64 m3/h that is equal to 1069 lit/min.

9- Water supply and firefighting booster pumps commonly ordered to DAMATAJHIZ by employers and project experts include LOVARA booster pumps, PENTAX booster pumps, GRUNDFOS booster pumps, ABARA booster pumps and PUMPIRAN booster pumps.

Pumps are divided into three groups based on their function in booster pump:

o Main pump: Pump(s) that provides head or total discharge of water supply or firefighting system.

o Jockey Pump: When high discharge is required in a system, large pumps are used and consequently electro-motors require high energy to move pump. On the other hand sometimes in consumption pattern little discharge is required and this discharge can be provided by a small pump and large pump is not required. In such cases a pump with less water supply capacity than main pump is considered to save energy and reduce depreciation of main pump; for little consumptions this pump is turned on to meet system requirement. This small pump is jockey pump. In addition when there is leakage in water supply system, water running in pumps and gradual pressure loss in system jockey pump is used to provide pressure (in variable speed booster pumps there is no need to jockey pump).

o Standby Pump: In public or important buildings in which continuous and uninterrupted water supply is critical and any interruption in water supply causes many problems and difficulties (such as hotels, hospitals and factories) a pump is considered as standby pump. Standby pump enters the circuit in case one of pumps stops or gets out of service.

Note: In booster pumps that are used for firefighting one pump shall be provided as standby pump.

Main parts of booster pump:

Main parts of fixed speed and variable speed booster pumps include:

o Electropumps, main chassis, diaphragm tank, and pressure switches for minimum and maximum pressure, pipes, suction and discharge collectors, related valves and fittings.

o Other parts of fixed speed booster pumps include fixed speed command and control panel.

o In variable speed pumps pressure transmitter, inverter and variable speed command and control panel should be used.

In the following paragraphs each of these parts is described.

10- Some water supply and firefighting booster pumps recently provided by DAMATAJHIZ include:

Further details about booster pumps

11- Since amount of consumed water in buildings is constantly changing, non-adjusted pressure of pumped water in pipes leads to some difficulties.

In fixed speed pumping systems in which one or more electropump continuously pump a certain amount of water into pipes, pressure in pipes changes by changes in amount of consumed water and these changes lead to some difficulties in water supply systems.

Instantaneous start of one or more electropumps and sudden increase in water pressure can damage pipes and valves. If one or more electropumps are turned off, water pressure decreases and can lead to water lo

Categorization of fixed speed booster pumps based on number of pumps:

o Single pump booster pumps: This kind of booster pump is used for sanitary water consumption in small and medium amounts. In this system that is quite integrated input collector is connected to power supply and output collector is connected to consumption network and just one pump circulates water in circuit.

o Booster pump with jockey pump: In these systems one or more main electropumps are used and an electropump with less capacity than main electropump and equal pressure with it is placed in the circuit as jockey pump.

o Booster pump without jockey pump: In these systems more than one main electropump is used.

o Note: In variable speed booster pumps there is no need to jockey pump as standby pump

Main elements in designing booster pumps include:

o Maximum water consumption

o Minimum pressure

o hourly fluctuations in water consumption

A brief description of booster pump components is provided here:

o Electromotor: In booster pumps electromotor is used as motor

In multi-pump booster pumps two or more electropumps are placed on a main chassis in parallel.

Electropumps should have appropriate insulation to have required efficiency in different regions and situations.

One of the other factors that should be considered is IP or amount of device protection against foreign bodies such as dust and water.

o Suction part: This part includes a tube collector that is connected to electropump suction part and storage tank output by the following valves and fittings:

Connect and disconnect valve: if one of pumps should get out of circuit a valve is used to fluid cutoff. In large booster pumps usually cast iron valves and in smaller booster pumps usually brass valves are used.

Filter: Filter is used to prevent potential entrance of particles in fluid to the pump that leads to pump damage.

Expansion joint: Applying expansion joint prevents transmission of pump vibrations to piping system.

Anges :In order to connect different parts (due to the booster pumps type , capacity etc .), welded or gear flanges could be used .

o Discharge part: Like suction part, this part is a pipe collector that is connected to consumption network by fittings and valves.

One-way valve: is used to prevent water return and consequent damages caused by water hammer effect.

Flange and union nut

Welt and converter

Connect and disconnect valve

o Control and electrical panel: electrical panel controls and coordinates electrical and mechanical parts of booster pump and its appropriate design has a great role in desired function of system.

Control and electrical panels should have safety verification and protect electromotors and pumps against possible problems such as severe power fluctuations and working without water.

Controller (PLC) is booster pump control and leads to appropriate pressure and discharge and even distribution of depreciation among pumps.

o Manometer: Manometer measures output and input pressure of booster pump and displays pressure of each pump.

o Pressure switch: Pressure switch controls minimum and maximum pressure and defines allowed pressure range in fixed speed booster pumps.

o Pressure transmitter: This device is used in variable speed booster pumps to control quite fixed water pressure.

o Coupling: If pump and electromotor are not coupled by coupling system out of pump, coupling is required to connect pump to electromotor. Coupling size is proportional to diameter of pump and electromotor shaft.

o Diaphragm tank: Considering in-compressibility of water, water pressure should always be constant in the system and water should be circulated by pressure provided by pump. This can be done by a diaphragm tank that stores water at a certain pressure.

On the other hand these tanks can prevent excessive start and stop of pumps and tensions caused by water hammer.

Although jockey pump in system can eliminate the need for diaphragm tank, simultaneous use of jockey pump and diaphragm tank prevents repeated start and stop of the main pump.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.