Thermal insulation, also known as heat insulation, is a practical solution designed to prevent the transfer of heat (and sound in most types) through building walls, ceilings, hot and cold water pipe surfaces, and floors to the outside environment. As a result, thermal and acoustic insulation materials are among the most essential components in construction, significantly reducing the energy demand for heating and cooling systems while minimizing energy loss and overall consumption. This is especially significant given the ever-changing and diverse climate conditions.

While some builders and contractors may initially skip insulation due to the upfront costs, in the long run, reduced energy consumption more than compensates for those early investments. Furthermore, heat insulator greatly reduces the release of pollutants into the environment.

In this article, we’ll explore the uses, properties, and advantages of various types of thermal insulation.

What is Thermal Insulation?

Thermal insulation refers to materials used to limit thermal transfer in buildings. The primary goal of using a thermal insulator is to prevent energy waste during both hot and cold seasons. In addition to maintaining a comfortable indoor temperature, these materials also help block moisture and reduce noise transmission.

Thermal insulation comes in a wide range of types, including mineral wool, fiberglass, polymer-based insulation, and different foam types. These materials are widely used in construction, petrochemical facilities, power plants, and more. Key features of heat insulation include long service life and high resistance to fire.

Different Types of Thermal Insulation

Thermal insulation is generally categorized into several types as follows:

- Mineral wool and fiberglass rolls

- Foam and polystyrene sheets in various thicknesses (with or without foil)

- Rock wool sandwich panels

- Polystyrene sandwich panels

- Polyurethane sandwich panels

- Pipe and cellulose-based insulation

In the following sections, we’ll cover the most commonly used types in more detail.

Fiberglass Thermal Insulation

Fiberglass insulation is made by blowing steam over fibers spun from molten glass. This fibrous structure provides flexibility and traps air in the voids between fibers. The density of fiberglass insulation ranges from 8 to 140 kg/m³, and it can withstand temperatures of up to 600°C.

Fiberglass consists of ultra-thin, interwoven glass threads that bond together as they cool. These are then layered onto kraft paper, lead foil, asphalt paper, or fiber mesh. Fiberglass insulation is fire-resistant and environmentally friendly. It’s widely used in sloped roofs (over underlayment layers) and flat roofs (beneath waterproofing layers, for example, bitumen or tile/mosaic).

It’s important to keep fiberglass insulation dry to prevent mold and bacteria from growing between the fibers. Its physical structure also provides excellent acoustic properties, making it ideal for soundproofing in building applications.

Slag Mineral Wool Insulation

Slag wool insulation is a type of mineral wool produced from blast furnace slag. For low-temperature insulation, the material is typically coated with bitumen-impregnated paper. For high-temperature applications, slag wool is reinforced with aluminum foil or galvanized mesh.

Slag wool insulation offers excellent fire resistance and inhibits the growth of mold and bacteria, making it superior to fiberglass in this regard.

Rock Wool Thermal Insulation

One of the most commonly used thermal insulation materials on the market is rock wool, which shares similar applications with other mineral wools. Rock wool is made from melted basalt rock, a byproduct of volcanic activity. It can withstand temperatures up to 750°C and is inherently fire-resistant.

This type of insulation is lighter than most alternatives and retains its properties even after drying. Its ease of installation and compatibility with all building materials have made rock wool a popular choice. It also resists mold and bacterial growth and is considered environmentally friendly.

One of the key applications of rock wool insulation is fireproofing. It’s often used to protect structural steel, elevator shafts, electrical installations, escape corridors, and other critical areas from fire.

Foam-Based Thermal Insulation

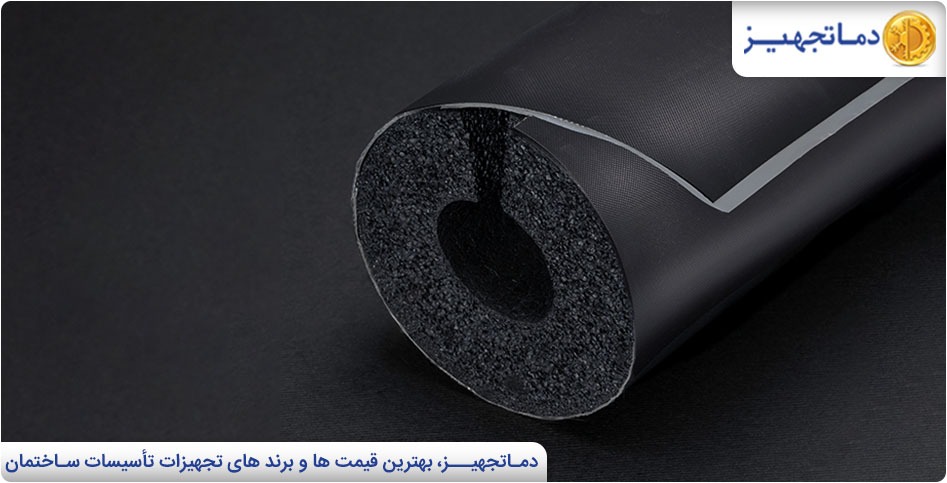

The wide variety of materials used in the production of foam insulation has led to a diverse range of thermal insulation products. Foam insulations such as elastomeric foam, polystyrene, polyurethane, phenolic foam, PVC (polyvinyl chloride) foam, EPDM (ethylene propylene diene monomer), nitrile rubber foam, and others are available, each offering unique properties and specific applications.

These foam insulations are produced and supplied in various forms and sizes, including rolls, sheets, and tubes, either with or without aluminum foil backing. They are widely used in buildings, mechanical systems, and various industries.

Mineral Fiber Thermal Insulation

Mineral fiber insulation is made by granulating and processing refractory volcanic rock. It’s a non-combustible thermal material that also provides acoustic insulation. This type of insulation is lightweight and resilient, often supplied as flexible mats, making it suitable for sloped roofs and beneath surface coverings.

A notable advantage of mineral fiber insulation is that it does not support the growth of mold or mildew, making it a clean and hygienic option.

Perlite Heat Insulation

Perlite is a naturally occurring volcanic mineral typically formed in humid environments. To enhance its insulating properties, it’s mixed with small amounts of water. During high-temperature processing, the water content evaporates, creating a porous, sponge-like structure. This structure helps trap air, reducing heat transfer and energy loss.

One key benefit of perlite is its inorganic composition, meaning it does not react with most acids and is highly resistant to decay and termite damage. Despite its advantages, perlite also has notable drawbacks to consider when buying. These include:

- Low compressive strength, making it unsuitable for high-pressure or highly humid areas

- High water absorption, due to interconnected pores, which reduces its performance when wet

Fiberboard Thermal Insulation

Fiberboard insulation was one of the earliest thermal insulators used in buildings. It’s made by compressing felted wool and other plant-based fibers into rigid boards. However, it easily absorbs moisture, leading to reduced insulating capacity and structural integrity.

Due to its low fire resistance, fiberboard is not ideal for building applications. Still, thanks to its low cost and dimensional stability, it is sometimes used—paired with a plastic underlayment—as a base for asphalt layers or felt roofing.

Compressed Cork Board Heat Insulation

Compressed cork board insulation is made by pressing cork granules together with natural resin. While this insulation is very expensive, it offers excellent moisture resistance, which makes it highly desirable in humid environments and various specialized applications.

However, it has low tensile strength, meaning it must be supported during installation to avoid sudden breakage. On the upside, compressed cork insulation offers high compressive strength, making it structurally robust in the right settings.

Cellular Glass (Foam Glass) Insulation

Foam glass insulation is a fireproof material created by expanding pure glass up to 30 times its original volume, forming rigid, sponge-like panels. Among its major benefits are:

- Excellent moisture resistance

- Insect and rodent resistance

- Non-combustibility

- High compressive strength

These features make foam glass insulation a reliable and durable solution in various thermal applications.

Choosing the Right Thermal Insulation

To make an informed and smart choice when selecting thermal insulation, it’s essential to understand the various types available, their rated thermal resistance (R-value), ease of installation, and overall value. It's equally important to consider performance characteristics, environmental factors, and safety precautions during installation and use. Below are several key features that define high-quality fire-resistant thermal insulation:

Pressure Resistance in Choosing Thermal Insulation

Once thermal insulation is installed, it may be subjected to structural pressure. Therefore, a reliable insulation material must be capable of withstanding mechanical stress without deforming or compromising its insulating performance.

Fire Resistance when Choosing a Thermal Insulation

One of the most critical criteria when choosing thermal or acoustic insulation is its non-combustibility. Fire-resistant materials significantly enhance the safety of buildings, preventing fast fire spread. This feature is especially vital in industrial environments and high-risk facilities where fire safety is a top concern.

Low Thermal Conductiveness

A lower thermal conductivity value indicates better insulation performance. Materials with a low thermal transfer coefficient are more effective at minimizing heat exchange, which helps maintain a stable indoor temperature throughout the year. This leads to energy efficiency and cost savings on heating and cooling.

Resistance to Mold and Fungal Growth

Proper hygiene is crucial in insulation systems. Materials that support mold or bacterial growth can compromise air quality and occupant health. Hence, mold resistance is a must-have feature in any high-performance insulation. Among the best in this regard are rock wool and slag wool insulations, both of which are highly resistant to biological contamination.

UV Resistance of Thermal Insolator

If the insulation will be exposed to direct sunlight—particularly in outdoor or rooftop applications—it must be resistant to ultraviolet (UV) radiation to avoid degradation over time.

Chemical Neutrality of Thermal Insulation

Thermal insulations should be chemically inert, meaning they don’t react with surrounding building materials or external elements. This chemical stability extends the insulation’s lifespan and prevents the release of hazardous by-products.

Flexibility Against Thermal Expansion and Contraction

Expansion and contraction due to temperature changes are inevitable in building materials. A high-quality thermal insulation must be able to adapt to thermal shifts without cracking, shrinking, or losing performance.

Review, Selection, and Pricing of HVAC Equipment

Thermal and Acoustic Insulation Advantages

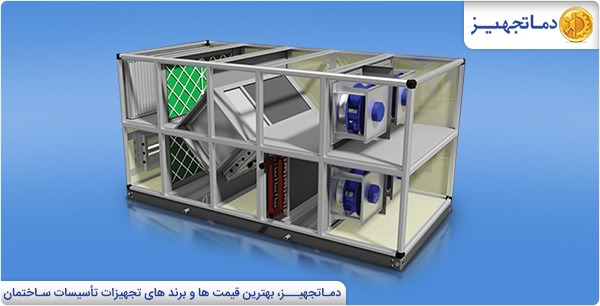

As mentioned earlier, thermal and acoustic insulation is widely used in walls, pipe linings, HVAC equipment, and industrial systems to slow down the transfer of heat to or from the external environment.

Here are some key advantages of using thermal and sound insulation materials:

- Protects building structures from thermal stress

- Reduces energy loss and enhances overall energy efficiency

- Improves building airtightness, contributing to better HVAC performance

- Quick and easy to install, reducing labor time and cost

- Simplifies quality control, thanks to standardized product formats

- Lowers noise pollution, creating quieter and more comfortable spaces

Installation Guidelines for Thermal and Acoustic Insulation

When installing thermal insulation, several key factors must be considered depending on the region's climate, construction method, and specific project requirements:

- The material and cladding of the insulation must be suitable for the operating temperature of the piping system and the surrounding environment.

- Insulation materials and their coverings must comply with national building codes and offer proper fire protection for the relevant building section.

- The use of flammable materials—including insulation, cladding, adhesives, or auxiliary components such as tapes—is strictly prohibited.

- Sections of piping that pass through firewalls must remain free of insulation or any type of cladding to comply with fire safety codes.

- If piping is at risk of freezing, the insulation thickness must be determined based on approved engineering standards or tables. In certain cases, alternative freeze protection methods may be required in addition to insulation.

Thermal Insulation at a Glance

The insights and information you've just read on thermal insulation are the result of years of research and experience by HVAC and building systems experts. Since 2004, DamaTajhiz—the first and most trusted online HVAC and building equipment retailer in Iran—has provided original products, competitive pricing, and professional consultation.

DamaTajhiz proudly offers a wide selection of thermal insulation products along with thousands of other HVAC and plumbing items, all with authenticity guarantees and valid warranties. To compare products, prices, and brands—or to make a purchase—you can contact our expert consultants during business hours at +9821-88822550.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet With You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |