Absorption Chiller

If you want to use an absorption chiller as the central core of your building's air conditioning system, stay with us until the end of this article to get the necessary information about the features, technical specifications, how to estimate capacity, choose the right brand, and purchase order tips for absorption chillers.

Expert Guide to Selecting Absorption Chillers and Prices

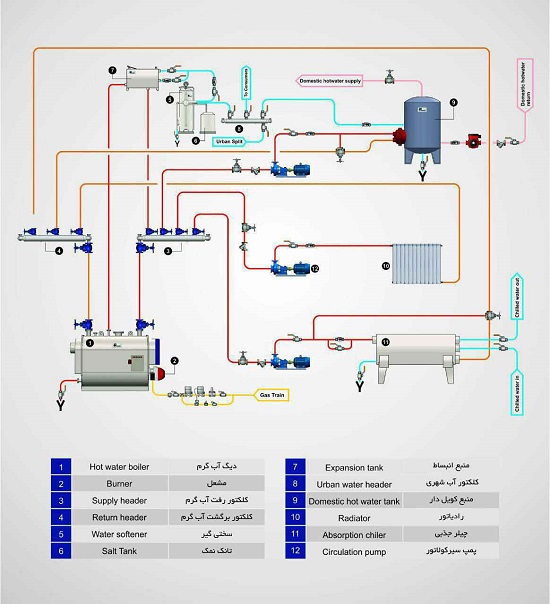

The absorption chiller is one of the refrigeration production equipment in air conditioning systems of buildings, which have much lower electricity consumption than compression chillers of the same capacity but require a lot of thermal energy (such as hot water - steam - direct flame).

This thermal energy evaporates the water dissolved in lithium bromide to create cooling in the absorption chiller generator. The resulting water vapor enters the condenser, where it is distilled due to contact with the water coils of the cooling tower and enters the evaporator.

Due to the presence of vacuum (0.01 atm pressure) in the evaporator, the evaporated distilled water absorbs its latent heat from the fluid coils of the air conditioning system (usually water). Then, the water vapor resulting from this process is absorbed by lithium bromide in the absorber; this diluted lithium bromide enters the generator by the solution pump. The dry lithium bromide is also returned to the absorber in order to absorb water and be diluted.

The refrigerant pump in absorption chillers is responsible for transferring water from the evaporator to the pipes carrying the fluid of the ventilation system.

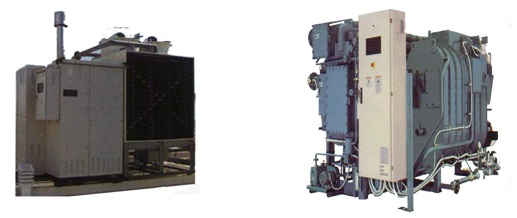

Classification of Absorption Chillers Based on the Energy Type

These four types of absorption chillers in terms of energy consumption:

- Spa absorption chiller

- Hot water absorption chiller

- Direct flame absorption chiller

- Vapor absorption chiller

The Main Components of the Absorption Chiller

The following are the main components of an absorption chiller:

- Generator

- Condenser

- Absorber

- Operator

- Solution pump

- Refrigerant pump

- Control valves

- Thermostats and relevant electrical panel

Factors to Consider when Buying an Absorption Chiller

Nominal cooling capacity and actual cooling tonnage of the device (TR)

Type of absorption chiller (spa, steam, hot water, direct flame)

For advice and to get more information about how to choose the absorption chiller you need, you can consult with the experts of DamaTajhiz HVAC Group.

In general, facility experts calculate the absorption chiller capacity required in each project, in addition to calculating parameters such as geographical conditions, altitude above sea level, relative air humidity, type of building use, type of materials used, and implementation of the building facade, the direction of the building relative to They pay attention to the sun's radiation angle, the number of floors and the surface of the building's substructure, the number of people and small and large electrical equipment inside the building, etc., the amount of cold water required and sufficient reliability coefficients in the performance of the absorption chiller.

But if you want to use the possibility of calculating the chiller required by residential and office buildings in climatic conditions like Tehran, you can consider the nominal capacity of 5 tons of refrigeration for every 100 square meters of the building. In absorption chillers, ammonia is the main source of energy supply for cooling city gas.

In lithium bromide absorption chillers (capacity above 30 tons of refrigeration), the main energy source is hot water or steam (except for direct flame absorption chillers, where the burner with suitable fuel is installed directly on it).

The Challenges of Choosing an Absorption Chiller for AC Systems

The following are the most common challenges of buying an absorption chiller:

- The initial purchase cost of absorption chillers is higher than water and air compression chillers with the same capacity.

- Higher dimensions and weight of absorption chillers than compression chillers with similar capacity

- Higher maintenance and management costs of absorption chillers than compression chillers

- The necessity of allocating more circulating water volume and cooling tower capacity (more water consumption) and choosing tower circulator pumps with higher capacity and pipes and connections with larger sizes in absorption chillers compared to compression ones.

- The loss of the relative and economic advantage of using natural gas fuel for energy supply due to the multiplication of the cost of gas consumed in the past years in absorption chillers

- The instantaneous performance efficiency or COP is lower, as well as the IPLV average performance efficiency is lower in all models and types of absorption chillers compared to screw, scroll, and especially centrifugal compression chillers.

In the absorption chillers group of the reference and specialized collection of DamaTajhiz HVAC Group, information and technical specifications of hundreds of models of absorption chillers from reputable domestic and foreign brands have been presented for your review and purchase, dear experts and employers.

A Word to the Employers, Consultants, and Contractors of Projects

Considering the variety and breadth of products and brands offered on the reference and specialized site of DamaTajhiz HVAC Groupon the one hand and the ability of this company to provide the most discounts along with the main guarantee of the manufacturing companies (due to constant communication and orders of DamaTajhiz HVAC with reliable manufacturers), you can purchase all the cooling and heating equipment needed for your project from different brands in one place through DamaTajhiz and save yourself from the trouble of contacting and following up with different companies.

Also, in order to create the greatest sense of trust and confidence for your loved ones, DamaTajhiz HVAC Group is able to provide the invoice and warranty card of the product manufacturer in your name or your company at the same time as the delivery of the goods.

Also, due to the fact that DamaTajhiz HVAC Group provides all kinds of absorption chillers in the Middle East region if you need absorption chillers for any of the countries in the region, you can place your purchase order with confidence, product guarantee, and reasonable price to our sales experts.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.