Resin Water Softener

Resin water softeners are available in automatic and semi-automatic types. In the following sections, we provide detailed technical information about different types of resin water softeners, their selection method, and capacity estimation.

Expert Guide to Selecting and Purchasing Resin Water Softeners

Water softeners are used to remove calcium and magnesium ions or mineral salts from water. Resin water softeners are considered one of the most effective solutions for removing suspended mineral compounds and dissolved salts from the water used in building heating and cooling systems. These units feature a highly durable cylindrical body made of galvanized steel or FRP, and their internal design includes layers of silica and resin media.

The necessity of removing water hardness or dissolved minerals by a water softener arises because these salts tend to deposit on heat transfer surfaces when water is heated or even cooled within mechanical and utility systems. Such surfaces include the inner tubes and combustion chambers of central heating boilers, coil tanks, heat exchanger surfaces, chiller condensers and evaporators, fan coil unit coils, air handling units, and other equipment. These deposits reduce heat transfer efficiency and consequently lower the overall performance of HVAC, heating, and industrial systems.

Types of Resin Water Softeners Based on Body Material

- Fiberglass resin water softener: The body is made of fiberglass and polyethylene, typically white or blue in color. These units are commonly referred to as FRP resin water softeners.

- Metal (galvanized) resin water softener: The body is manufactured from steel or galvanized sheets. Compared to fiberglass models, metal resin water softeners offer higher operating pressure and capacity, making them more suitable for larger, taller, and industrial buildings.

Review, Selection, and Pricing of HVAC Equipment

Types of Resin Water Softeners Based on Multi-Port Valve Operation

- Semi-automatic resin water softener: Due to the use of a manual solo valve, the timing for backwashing and resin regeneration is not detected automatically. Therefore, an experienced operator is required to perform weekly or monthly resin regeneration operations.

- Fully automatic resin water softener: Resin regeneration and cleaning (backwash) is one of the most critical processes after hardness removal in resin water softeners. In some units, this process and its timing are carried out automatically without human intervention. These units are referred to as fully automatic resin water softeners.

Types of Resin Water Softeners Based on Structure and Configuration

- Single-tank resin water softener: This configuration includes only one tank into which hard water enters. After passing through the resin layers, the water becomes soft and is discharged from the softener tank.

- Dual-tank resin water softener: This type consists of two tanks, allowing the standby tank to continue the softening process while the other tank undergoes resin washing or regeneration.

Selection of Semi-Automatic and Automatic Resin Water Softeners

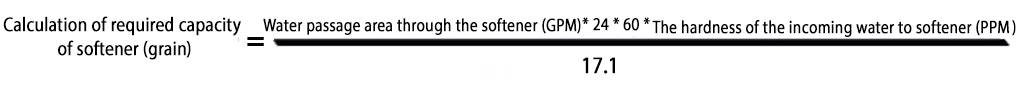

To calculate the required capacity and select an appropriate resin water softener, after determining the volume of water consumed in the closed-loop heating and cooling system of the project and measuring the hardness of the local water supply (using available test kits or dedicated instruments), the softener capacity can be accurately calculated using the formula provided below.

Please note that resin volume, softener dimensions (such as diameter and height), and body material are key specifications of resin water softeners. Manufacturers typically provide general specifications, including service flow rate, regeneration flow rate, and fast rinse flow rate, based on which the required resin volume can be calculated.

To select and purchase a semi-automatic or automatic resin water softener, the capacity and type must first be determined.

The following formula can be used to calculate the capacity of a resin water softener

To calculate the required capacity of a resin water softener, after determining the volume of water used in the closed-loop heating and cooling system and measuring the hardness of the project site water (using available test kits), the above formula can be applied to obtain an accurate result.

DamaTajhiz; selection and purchase of HVAC and mechanical equipment (since 2004)

At the specialized Damatajhiz group, technical information for dozens of resin water softener models from reputable brands with original warranties has been provided to ensure a smart and optimized purchasing experience.

Advantages of Resin Water Softeners

- Reduces the possibility of calcium and magnesium sulfate scaling in water piping and heat exchange equipment

- Saves operational expenses and energy in mechanical and industrial systems

- Extends the service life of piping, HVAC equipment, and boiler room installations

DamaTajhiz; Guide to Selection and Pricing of HVAC and Building Facilities Equipment (Since 2004)

How Resin Water Softeners Work

In resin water softeners, the water softening process is carried out using the ion exchange mechanism. In this process, ion exchange resins absorb the hardness ions present in water and replace them with sodium ions. Sodium ions are stable in water and do not form scale; therefore, water containing sodium ions is referred to as soft water. It should be noted that selecting the appropriate type and quantity of resin depends on the level and type of water hardness.

After a certain period of operation, resin water softeners lose their ion exchange capacity. When the resins can no longer perform effective ion exchange, they must be washed with a saline solution or 10% sodium chloride solution to restore their ion exchange capability. Before the brine solution passes through the resin, the resin bed is first rinsed with water to prevent salt from entering the central heating system water, as salt is highly corrosive and can cause serious damage to mechanical and utility equipment.

Important Considerations for Selecting a Resin Water Softener

- Inlet water hardness in PPM

- Inlet water flow rate to the resin water softener

- Type and capacity of the resin used

- Time allocated for regeneration and washing cycles in semi-automatic resin water softeners

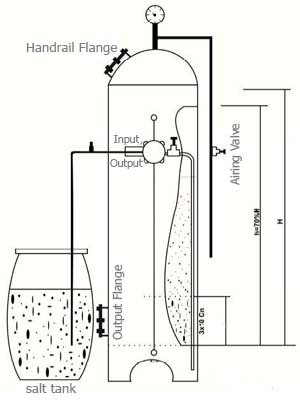

Main Components of a Resin Water Softener

- Resin water softener tank:

The tank or vessel designed to contain the resin layers and allow water to pass through them is one of the most critical components of a water softener. - A critical consideration for the softener tank is its high resistance to water pressure, mechanical impact, and corrosion.

- Resin water softener nozzle:

After calcium and magnesium are removed from the water, and it is converted into soft water, the treated water is collected through the nozzle. - Water softener resin:

Resin beads are among the key components of resin water softening equipment and are available in cationic and anionic types, typically placed at the lowest level of the tank. With prolonged use and the presence of minerals such as copper and manganese in water, resin performance gradually degrades, making replacement of the resin layers necessary. - Multi-port valve of the resin water softener:

In semi-automatic and fully automatic resin water softeners, the backwash process of the resin layers is performed. This operation is carried out by adjusting the solenoid valve position, which is done automatically in automatic softeners without manual intervention by an operator. - Salt tank of the resin water softener:

To regenerate the resin layers and enhance their efficiency after contact with iron and manganese in the water, a small salt tank is installed next to the main resin water softener tank. - Drain line

- Silica bed

- Inspection port

DamaTajhiz: Thousands of products for thousands of projects (since 2004)

Applications of Resin Water Softeners

- Prevention of scaling and clogging in valves and piping of mechanical systems

- Used for softening water in steam boilers and heat exchangers

- Prevention of mineral scale formation on heat transfer surfaces in heating, HVAC, and industrial systems

- Softening process water used in paint manufacturing and dyeing industries

- Supplying make-up soft water for boilers, reactors, and steam generators

- Application in laundries and large restaurants

- Use in reverse osmosis processes or deionization systems

Price of Semi-Automatic and Automatic Resin Water Softeners

The price of semi-automatic and automatic resin water softeners varies depending on model diversity and capacity, body material, and available brands. It should be noted that the prices offered by Damatajhiz are up-to-date and include the discounts expected by consumers. By visiting Damatajhiz, you can review various types of resin water softeners at the best prices to make the most suitable purchasing decision.

Dear User,

- If, after reviewing the information provided above, you have additional questions regarding the purchase of resin water softeners, you may contact the DamaTajhiz team via internal extensions 107 - 108 - 121 - 122 and receive consultation from sales experts in the heating and boiler room equipment department.

You can order any HVAC and MEP products, including different types of air washers, cooling towers, air handling units, chillers, industrial evaporative coolers, air curtains, burners, cast-iron or steel boilers, heat exchangers, gas heaters, unit heaters, circulation pumps, sand filters, water and fuel storage tanks, and more, from countries such as the UAE, Armenia, Tajikistan, Georgia, Azerbaijan, Turkey, Oman, Pakistan, Turkmenistan, Afghanistan, Kuwait, Bahrain, Qatar, Iraq, and others across Asia, the Middle East, and Europe, and have them delivered to your city (Manama, Baghdad, Karachi, Dubai, Sharjah, Muscat, Riyadh, Abu Dhabi, Kuwait City, Jeddah, Sana'a, and Doha Amman, Sulaimaniyah, Sofia, Kirkuk, Islamabad, Mosul, Erbil, Dushanbe, Aleppo, Damascus, Baku, Beirut, and Kabul) in the shortest possible time. So, contact us by phone call or WhatsApp message through the number: +98-930-288-0251.

"Knowledge Fuels Better Choices"

Registered Trademark and Stewardship Business Licenses Issued by the Union of Virtual Business Association and the HVAC Equipment Industry.

DamaTajhiz HVAC Participation at International HVAC and Construction Facilities Exhibitions Demonstrates its Global Reach and Commitment to the Industry.

We Look Forward to Your Call and the Opportunity to Meet You

SHARE THIS CONTENT TO SPREAD THE KNOWLEDGE

| |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.