Damatajhiz Semi automatic Resin Softener Grain 120000

- Working pressure: 4 bar

- Dimensions (height, diameter): 150 * 40 cm

- Can be ordered in two types with aqualite or purolite resin

- Manufacture of various types of resin hardeners in the form of duplex or triplex, covering the inner surface with epoxy paint

- Contains accessories such as salt tank, granulated silica, pressure gauge

Guide for selecting and purchasing Damatajhiz Semi automatic Resin Softener Grain 120000

In general, resin softeners are responsible for removing suspended mineral compounds and water-soluble salts in heating and cooling systems. Unstable calcium and magnesium ions resulting from calcium and magnesium bicarbonate salts in water are affected by the heat of water exchange to a stable precipitate of calcium carbonate and magnesium carbonate and sediments on heat exchange surfaces in heating cooling systems. The formation of stable sediment on the heat transfer surfaces of devices such as air conditioners and fan coils, condenser and evaporator chillers, internal surfaces of cast iron boilers, and the surface of steel boiler tubes and heat exchangers, reduces the heat exchange efficiency in these pieces of equipment. By using resin softeners by ion exchanging you can remove these destructive and harmful elements and sediments.

Semi-automatic resin water softeners manufactured by Damatajhiz Engineering Company are offered with excellent quality, warranty, and after-sales service of Damatajhiz in various capacities and with many features compared to similar products.

Important points when buying a Damatajhiz Semi automatic Resin Softener Grain 120000

- The most important point in using semi-automatic resin softeners is the need for the regular and periodic presence of the operator for maintenance and permanent softener backwash.

- One of the essential tasks of the service worker in the engine room is to perform backwash operations (removal of water hardness and sedimentation of softener device) in semi-automatic resin softeners. This operation should be done regularly and periodically according to the instructions provided by the engine room operator. If the backwash operation of the semi-automatic resin softeners is not performed, sediments and water salts will accumulate in the machine and after a while, the resin water softener will be completely out of order.

The difference between automatic and semi automatic resin softeners

Backwash and reduction operations in resin softeners with semi-automatic valves are performed regularly and supervised by the engine room operator and in fully automatic resin softeners without the need for an operator and based on a flow or time adjustment system automatically.

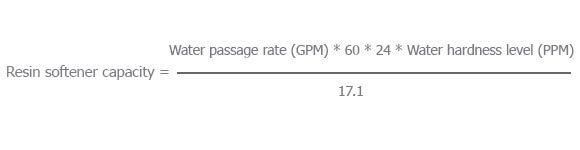

Resin softener capacity calculation formula

To calculate the required capacity of different types of resin softeners, after determining the amount of water used in the project and measuring the amount of hardness of the project site (using special kits available in the market or its special tools) you can estimate the resin softener's capacity using the following formula accurately enough.

Features of semi-automatic resin softeners

- Ion exchange process

The advantage of resin softeners compared to other types of softeners is the removal of water hardness by ion-exchange process, which can be seen to reduce water hardness in this method by using hardness measuring kits, but in other types of hardeners (descalers), salts in The water is kept suspended and it is not possible to remove or reduce the hardness of the water.

In heat-resistant softeners, models with the letter P and filled with the symbol ˝ are softeners with British Prolite resin, which are stronger in terms of ion exchange capacity and more expensive.

- Equipped with accessories

All thermosetting resin softeners, in addition to having a 3-way semi-automatic valve with relevant piping and nozzles made of polyvina (resistant to corrosion and fragility), have relevant accessories such as a salt tank, granulated silica, gauge or manometer Are water and resin pressures.

- Work pressure

The working pressure of the resin softener is 4 bar (equipment) and the thickness of the body plate and its upper and lower lenses are calculated and determined based on the capacity and size of the device.

- Protection and standards

To protect the inner wall of the water softener and the standard outlet water of the device, the inner surfaces of the temperature resin hardener of the equipment are covered with an epoxy paint coating.

- Build all kinds of your orders

Damatajhiz Engineering Company produces orders for all types of duplex and even triplex resin softeners, observing all technical engineering standards.

Instructions for setting up a Damatajhiz resin softener

- First, pipe the resin softener after placing it on the appropriate foundation according to the description on the previous page.

- Then open the lower flange of the stiffener and gently pour the coarser grain silicas into the machine on the nozzle plate. (Be careful not to damage the nozzle.)

- Then flatten it and close the bottom flange completely and seal it.

Now open the top flange and pour the finer silica into the Resin Softener onto the larger silica. - Drain the resin bags completely on the silica cast in the softener and seal the top flange tightly.

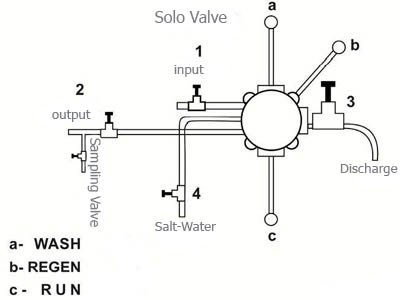

- Set the multi-way valve lever to position No. 3 (RUN) and close valve No. 2 (outlet) and open valve No. 4 (drain) and valve No. 1 (inlet) for 5 minutes to wash the device silicas.

- Then close valve number 4 (drain) and put the multi-way valve on position number 1 (WASH) for 10 minutes to wash the resins of the device.

- Set the multi-way valve to position number 3 (RUN) and vent the softener through valve number 6.

- By opening valve number 2 (outlet), the softener is ready for operation. (Prepare the device for the recovery step by adding salt to the salt tank and adding water.)

Important points in the operation of Damatajhiz resin softeners

When buying water softener 120000 grains of Damatajhiz, please notice these important points:

- The hardness of the water leaving the softener must always be controlled through the sampling valve by the hardness tester kit. As soon as the water hardness exceeds the allowable limit, you should start resin reduction.

- When regenerating the resin, make sure that the pressure inside the softening tank is between 1.7 and 3.5 bar. If the pressure inside the tank is low, the suction of saltwater will be disturbed and at high pressures, the multi-way valve parts may be damaged.

- It is better to use a pressure relief valve at pressures higher than 4.5 times before the multi-way valve inlet, or at least when changing the position of the multi-way valve handle, close valve number 1 (inlet) to avoid sudden pressure on the multi-way valve. The way is prevented.

- Be sure to note that the use of high purity crystallized salt is recommended. Because if you use rock salt or ordinary salt, due to the impurities in the salt, the life of the resin is greatly reduced and the resin is not completely regenerated.

- The amount of saltwater suction in the factory is pre-set. If necessary, it is possible to reset the suction of saltwater behind the multi-way valve next to the saltwater pipe. The amount of suction should be such that the resin is reduced with brine with a concentration of about 10%.) The reduction of suction of brine can be due to reduced pressure inside the softener. It is also necessary to control that the factor does not clog the saltwater path.

- The use of muddy waters with suspended solids, as well as waters containing iron, manganese, copper, and other heavy metals, hardens the softening resins quickly and reduces the yield of the softening device. Therefore, it is recommended that the suspended solids in the water be separated from the water by a filter before the water enters the hardening device.

- When moving the multi-way valve handle, gently pull it towards you and position it. This is because the internal parts of the valve may be damaged if it is dropped suddenly.

- It is recommended to lubricate the multi-way valve once a year from the gap between the cap and the valve body with ordinary grease without opening the multi-way valve.

- It is essential to prevent the resin and water from freezing in the softener. Freezing destroys the resin.

Setting up and installation of semi automatic resin softeners with Damatajhiz metal tank

Temperature softener equipped with chemical treatment of water and with the help of special resins (anionic, cationic) according to the buyer's needs, completely soft water with low cost for installation and industrial uses such as boilers, steel boilers, cast iron boilers, cooling towers and Provide other industrial and public uses to consumers. These types of stiffeners operate semi-automatically, which is described below.

Preliminary operation Set up the stiffener after installing the device in the desired location

- Connect the inlet and outlet water pipes of the device to the system.

- After opening the lid (hand flange), make a bed with silica and cationic or anionic resin according to the shape, and then close the valve (hand flange) tightly by closing the star.

- Place the salt tank (containing a solution of water and salt of suitable concentration, 250 grams of salt per liter of resin must be dissolved) under the saltwater pipe of the device.

Installation of semi-automatic resin softener for Damatajhiz metal tank

- First, close all the valves and open the vent valve of the device. (first diagram)

- Set the handle of the solo valve to Run.

- Open valve number 1 in figure number 2 (input), in this case, the tank of the device gradually fills with water.

- Close the vent valve as soon as the water comes out of the vent pipe.

- Open valve number 2 in figure number 2 (outlet), so the device is ready to operate and soften the water.

- Note 1: During the operation of the semi-automatic metal resin softener, make sure that the relative pressure inside the tank is between 1.7 to 2.5 bar (Bar) (via barometer installed on the device)

- If the pressure inside the tank is less than 1.7 Bar (bar), the sealing of the solo valve and the suction of saltwater will be disturbed, and at a pressure higher than 6 bar (Bar) the solo valve parts may be damaged.

- Tip 2: Never use the solo valve at pressures higher than 2.5 bar while working or operating.

- Tip 3: The hardness of the treated water The output of the softeners should always be checked and tested with a test kit, and as soon as the hardness of the water exceeds the allowable limit, the resin reduction procedure described below should be performed immediately. Took action. On average, this operation is performed once every 2 weeks.

How to regenerate hardening resin

- First, close valves 1-2-3-4 in Figure 2.

- Position the solo valve handle in the Regen position.

- Open valves 3 and 4 to allow water and salt solution to enter the system. If you open the lid on the salt nozzle, which is installed for this purpose behind the solo valve and next to the drainpipe, the suction rate can be adjusted with the help of a suitable screwdriver. (Some drain water and saltwater are replaced)

- After the required time, do the next step, washing the resin with water.

Washing the resin with water

- Close all valves first.

- Put the solo valve in the Wash position.

- Open valves 1 and 3 (inlet and outlet valve), in which case water enters the tank from the bottom of the resin column and exits from the top.

- Wait about 20 minutes to wash all the resin inside the tank and drain the water and salt solution.

- Close all valves and open valve number 1 (inlet).

- Then put the solo valve handle in the Run position. In this case, the device is ready to work again.

List of recent projects of semi-automatic Damatajhiz resin softeners

If you wish, you can visit the following projects after coordination with Damatajhiz Company.

- Mr. Pour Hamzeh project: Semi-automatic heat-resistant resin softener with a capacity of 600,000 g

- Bahman Group 2 site: Semi-automatic thermal softener with a capacity of 60,000 g

- Zarrin Nema Construction Company: Semi-automatic thermal softener with a capacity of 250,000 grits

- Fereshteh Street Terrace Park Project: 500,000-Grain Duplex resin softener

- Arman Pooyesh Abtin Project: Semi-automatic thermal resin softener with a capacity of 250,000 g

- Omid 2 project: semi-automatic thermal resin softener with capacities of 1,500,000-grain duplex and 60,000-grain

- Abu Reihan Clinic Clinic: Semi-automatic resin softener with a capacity of 120,000 g

- Arsh Bana Company Made in Yazd: Semi-automatic thermal resin softener with a capacity of 600,000 g

- Soil to Allarce makers: Semi-automatic thermal resin softener with a capacity of 250,000 g

- Lean Eagle: Semi-automatic thermal softener with a capacity of 30,000 grit

- Marvdast Hospital: Semi-automatic thermal resin softener with a capacity of 60,000 g

- Azarakhsh Optimizers: Semi-automatic thermal resin softener with a capacity of 150,000 g

- General Justice of South Khorasan: Hardened resin softener with a capacity of 450,000 g

- Ekbatan Megamall Project: Semi-automatic thermal resin softener with a capacity of 1,400,000-Grain Duplex

- Pak Afarin Pooyesh Isfahan factory project: semi-automatic thermal softener with a capacity of 600,000 g (1 piece)

- Pourateb Holding Company: Semi-automatic resin softener with a capacity of 300,000 g (2 pieces)

- Chitgar Lake Frantium Project: Heat-resistant resin softener with a capacity of 1,000,000-grain double

- Sedfam Toos Company: Hard resin softener with a capacity of 120,000 g

- Madiran Company: Semi-automatic thermal softener with a capacity of 1,000,000 g

- Taleghani Hospital, Tabriz: Semi-automatic thermal resin softener with a capacity of 800,000 g

- Bu-Ali University of Hamadan: semi-automatic heat-resistant resin softener with capacities of 90,000 -150,000 -200,000 - 40,000 - 500,000-Grain

- Razi University of Kermanshah: Semi-automatic thermal resin softener with a capacity of 30,000 g

- Ministry of Interior (Central Building): Semi-automatic thermal resin softener with capacities of 1,000,000 and 90,000

- Sina Concrete: Semi-automatic heat-resistant softener with a capacity of 150,000 g

- Dross Shahd Farin Company: Semi-automatic thermal softener with a capacity of 120,000 grit

- Rahravan Tose'e Asr Co. (Valiasr 200-unit project): Duplex resin softener equipped with a column with a capacity of 750,000 g

- Urmia Koran fish farming: Hardened resin softener with a capacity of 120,000 g

- Provincial Project (Pars Abriq Company): Hardened resin softener with a capacity of 1,200,000-Grain Duplex

Purchase and warranty of Damatajhiz Semi automatic Resin Softener Grain 120000

- Damatajhiz Semi automatic Resin Softener Grain 120000 has 3 years golden warranty from DamaTajhiz Company and 10 years of after-sales service.

- Damatajhiz Engineering Company has provided technical information and guaranteed prices for all types of semi-automatic resin softeners with Damatajhiz with a golden guarantee for your dear ones to enjoy a good sense of optimal and smart purchase.

- The price of all semi-automatic resin softeners provided in the reference site has been updated and the discounts desired by the esteemed employers have been included in these prices so that these prices also include the best price guarantee section of the heated site. (Refer to the best prices guarantee section of the Damatajhiz website)

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.