Water Consumption in Cooling Towers

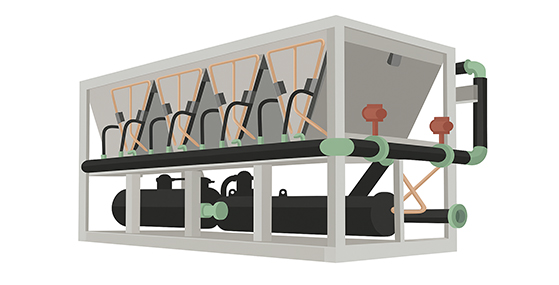

Cooling towers are heat exchangers used to cool condenser water in HVAC systems and various industries. They come in two main types: open-circuit (wet) and closed-circuit (dry), with the open type being more common due to higher efficiency. However, in water-scarce regions like Iran, water usage in open cooling towers.

Table of Contents

Fast shipping nationwide

Secure payment

Valid warranty

After-sales service

Address

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

Phone

Fax

Email

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.