Choose and purchase guide for Damatajhiz 200-ton Cross Flow Cooling Tower

The Damatajhiz 200-ton Cross Flow Cooling Tower is one of the new generation models of Damatajhiz cooling towers with a cross-flow type cube shape which is produced with the possibility of air suction only from the two sides of the device.

It should be mentioned that, by using the new design and technology in the construction of the cubic cross flow cooling towers of Damatajhiz, all the limitations and disadvantages of the old generation of cooling towers (circular towers) have been completely removed.

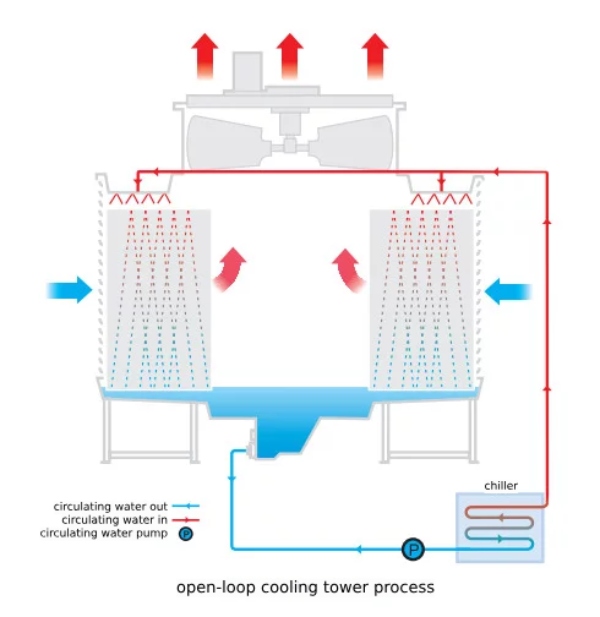

Open circuit cooling tower performance

As you know, the cooling of water in cooling towers is achieved through the movement of water in the device and the evaporation process, on the other hand, due to the evaporation of water, the salts and impurities in it remain as deposits inside the cooling tower device. stayed

Sediment formation in cooling towers has a direct relationship with the quality of water entering the device, therefore, in projects where the water circulating in the cooling tower must be of high quality and the possibility of sediment formation in the device is also low, cooling towers The circuit breaker is used.

With the airflow inside the cubic cooling tower and the cooling of the circulating water, some of the water in the cooling tower is always evaporated. After cooling the water in the cooling tower, cool water is collected in the basin and the lower part of the device and is directed to the chiller or the production process by circulation pumps.

The advantages of the new generation of Damatajhiz 200-ton cross flow cooling tower

- Lightweight and small size

- Ultra-quiet construction series

- Using an electric motor from the best available brands with a long lifespan

- Equipped with plate packings with an anti-adhesion property of sediment to it

- Equipped with an inspection valve for periodic service visits to the device

- Equipped with an aluminum propeller with a special design to reduce the production noise

- The main skeleton of the tower is made of hot water-treated steel (anti-rot and rusting).

- Low-consumption mobile phone (more than 30% saving in water consumption)

- The possibility of air suction only from both sides of the device (does not occupy a lot of space on the roof)

- Easy access to the interior of the cooling tower to wash the packing

- Internal packings made of P.V.C material with medical grade and resistant to sunlight and anti-fragility properties

- The use of new technology in the uniform distribution of water by gravity (no need for a water dispenser and related problems)

- The possibility of easy access to the upper space of the cooling tower for periodic visits to the mechanical equipment of the device (equipped with a ladder with protection made of hot weathered steel)

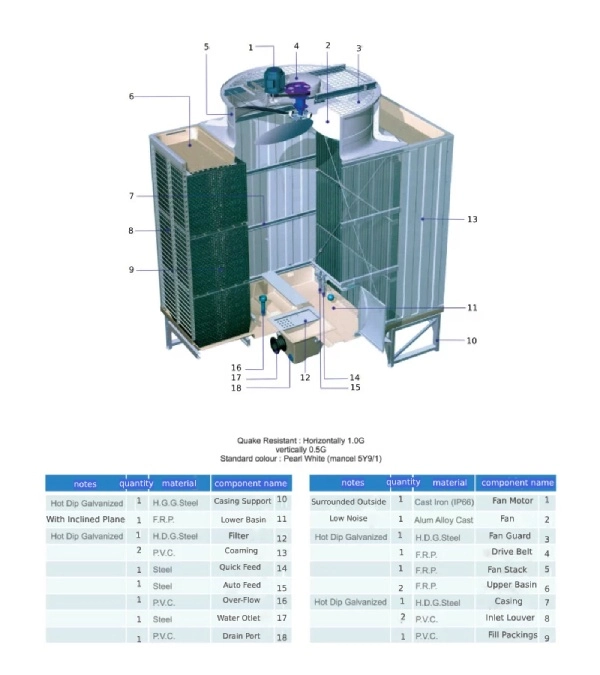

Technical specifications of Damatajhiz 200-ton cross flow cooling tower

1. Long life and low weight:

The use of a special alloy (H.D.G. hot water-treated steel) in the design and construction of the new generation Damatajhiz crossflow cooling tower (with anti-rot and rust properties) has increased the resistance and longevity of this device. increased to a significant extent and their weight also decreased.

2. Shallow sound:

In the new generation of Damatajhiz cross flow cooling towers, to further reduce the sound level, the device's fan is designed with special angles and made of aluminum alloy, and for this reason, the device's sound is significantly reduced. which is 10 meters away from the device, the maximum sound is 51 decibels.) Thus, these cooling towers can be introduced as the quietest device among similar products.

3. No shaking or vibration:

The special design and precise and solid construction of the cooling tower skeleton and other vibrating parts of the device in the new generation of thermoequipment cubic cross-flow cooling towers are such that the device is free from any vibration and is vibrating.

4. Electric motor with high efficiency and minimal energy consumption:

- The electric motor driving the propeller in these towers is of the three-phase type (class IP=54) and is one of the best brands, which has a long life and high efficiency, with the possibility of connecting to a device that changes the speed of the motor (inverter). By using this feature (inverter) in cubic cooling towers, the power consumption of the device is intelligently controlled and its consumption (energy) can be significantly saved.

- It should be noted that the use of this equipment (inverter) in high-capacity cooling towers and also in projects such as drug production industries, plastic injection industries, steel industries, food industries, etc., which are required for the production process It is recommended that they have high-temperature sensitivity.

5. Minimum energy consumption in partial loads:

The new generation of cubic cross flow cooling towers manufactured by Damatajhiz company are made in different capacities from 50 to 250 tons of refrigeration, therefore, for larger projects, multiples of these capacities can be used in any number and according to the needs of the complex. (multi-cell) assembled and installed. In this way, when the chiller is working under partial load, the electric motor of one of the cells is turned off, and as a result, the amount of electricity consumption of the device is reduced to a significant extent.

6. The need for a small and limited installation space:

The skillful design of the new generation of Damatajhiz cross-flow cooling towers has caused all the air needed by the device to be supplied from only two sides. Therefore, in projects that require the preparation of several devices, the devices are placed together easily and without lateral distance (from the other two sides). This advantage of the cross-flow cube cooling tower of the temperature equipment causes a significant saving in the installation space of the device (especially on the roofs of residential units that have limited space).

7. The main skeleton of the cooling tower:

As you know, the main skeleton of the cooling towers creates the static resistance of the device and is very important.

The main skeleton in the new generation of Cross Flow cooling tower is made of hot dipped galvanized steel (HDG) with long life, low weight, and very high resistance against high humidity and unfavorable weather conditions.

8. Air intake shutters:

- The air intake shutters installed on both sides of the device carry out the work of uniform transfer of air to the space inside the cooling tower to cool the water.

- The material of the shutters in the Damatajhiz cross-flow cooling tower is made of very high-quality fiberglass that is resistant to sunlight and unfavorable weather conditions.

9. Internal packing with special design:

- The internal packings of the Damatajhiz 200 ton cross-flow cooling tower are produced in two types of splash (honeycomb) and plate according to the type of use.

- In air conditioning applications and processes where the hot water entering the cooling tower does not have a high temperature, it is recommended to use plate packings with a temperature resistance of up to 55 degrees Celsius.

- The material of these packings is PVC type and has very high flexibility (with anti-brittleness properties) which is resistant to sunlight.

- The packings used in the cross-flow cooling towers are equipped in such a way that their surfaces have a very high polish and prevent the adhesion of sediments resulting from evaporation.

- Among the other advantages of using screen packings, we can mention the possibility of their easy replacement and installation (depending on the required number) and the possibility of de-scaling and easy washing of the packings (without the need for acid washing and paying related costs).

10. The main chassis of the cooling tower:

- As you know, the total weight of the cooling tower is placed on the chassis of the machine, and for this reason, the material of the main frame and chassis of the cooling tower is very important.

- The main chassis material of the Damatajhiz 200-ton cross flow cooling tower is one of the new generation models of the Damatajhiz cubic cooling tower, with a special design made of hot water-treated steel (H.D.G), which is resistant to rust. and rotting, due to the proper stability of the device, it maintains its stability for many years without any vibration during use.

11. Maximum air circulation with less energy consumption:

- In the new generation of Damatajhiz cross-flow cooling towers, the fan blades have a super blade material and are made of aluminum alloy with very lightweight and high strength.

- The precise design and shaping of the aluminum fins with specific angles along with the quality of construction in the new generation of the Damatajhiz cross flow cooling tower has caused, in addition to a significant reduction in the noise of the device, the highest amount of air circulation with the lowest consumption of electricity in The electromotor of the device is also obtained.

12. butterfly guard:

In the Damatajhiz cubic cross-flow cubic cooling towers, in order to prevent the entry of objects or objects into the device's propeller chamber, the upper surface of this chamber in these cooling towers is completely protected and covered with a metal net made of hot galvanized steel (anti-rust).

13. ladder:

- To easily access the upper space of the Damatajhiz 200 ton cross-flow cooling tower, during visits and periodic services and possible repairs of the device, a hot galvanized steel ladder is placed on one of its corners.

- It should also be noted that the possibility of installing fencing, and protection around the cooling tower, and also the entrance stairs (for ease of entry into the cooling tower) is also available according to the order of the respected buyer.

13. Side walls:

- The side walls of the Cross Flow cooling towers are made of fiberglass and are very resistant to sunlight.

- The construction of these walls is such that while having a beautiful appearance, it completely traps the air inside the device and allows air circulation to increase the cooling power only on the surfaces of the packings.

14. Filter installation:

Due to the possibility of suspended particles and sediments due to water evaporation passing through the cooling tower and damaging the impeller of the circulator pump, condenser, chiller, or other related industrial equipment, therefore, the Damatajhiz cross-flow cooling tower is made of mesh strainer with stainless steel material. Steel is used in the way of the water coming out of the pan of the device.

15. Access door and easy maintenance and repair:

- A valve has been installed on one of the side walls of the cooling tower for the technical technician to enter the device.

- The existence of the inspection valve provides easy access to the inner space of the cooling tower, for periodic visits, descaling, and easy washing of the packings and their possible replacement. (In this case, the descaling process in the previous generation of cooling towers was possible by using the acid washing method and paying a lot of money and with many problems.)

16. Antifreeze heater:

In industrial projects where the cooling tower is used as a part of the production process, the device is on and working all year round, including the winter season. Therefore, due to the possibility of cooling tower water freezing at certain hours of the day and night (autumn and winter seasons), in the design of the new generation of Damatajhiz cross-flow cooling towers, the heating system is used to prevent freezing. Water is considered, which can be installed and provided on the device according to the order of respected customers.

The main disadvantages of the old generation of cooling towers (circular cooling towers)

- The low lifespan of the device

- More energy consumption (more electricity cost)

- Too much water splashing out (too much water wastage)

- Very expensive repairs including forced replacement of all packing

- Rapid clogging of sprinkler water nozzles in short time intervals

- Occupying more space for more air suction and larger dimensions of the device

- Causing premature injuries due to the breakage of the motor shaft in water distribution

- A lot of noise and vibration due to having a large capacity electric motor

- Conclusion: Based on the above information, it is concluded that by using the new generation of Damatajhiz cross flow cooling towers, the current costs of these devices (including the cost of electricity, water, and the cost of repairs and service (seasonal costs of the device) has been significantly reduced and the useful life of the device has increased.

In addition, the quality improvement of the new generation of cooling towers has made it easier to make the final decision, due to the safe selection of the device. In such a way that the respected buyer buys the device with confidence in the quality of the device.

It should be noted that our colleagues in the specialized collection of Damatajhiz are always ready to answer your questions to buy Damatajhiz cooling towers, dear users, regarding obtaining satisfaction and a successful shopping experience in this field.

Purchase order and warranty of Damatajhiz 200-ton cross flow cooling tower

- The 200-ton cross-flow cubic cooling tower of Damatajhiz has 15 months of Dematheiz golden warranty and 10 years of after-sales service.

- In the reference and specialized collection of Damatajhiz, the technical specifications and the best price of the cooling tower of Damatajhiz in different types and models with a golden guarantee have been presented in order for you, dear ones, to enjoy the good feeling of an optimal and smart purchase.

- To view and learn about the warranty and technical specifications of the Damatajhiz cooling towers, click on the "Technical Specifications" tab on the page of each product.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.