Chauffagekar Cast Iron Boiler Super 500 with 9 blades

- Heating energy(input): 304,000 kcal/h

- Heating energy(output): 258,000 kcal/h

- Number of blades: 9

- Working pressure: 4 bar

- Fuel type: natural gas or gasoline

10 Years Warranty

10 years

Guide for buying a super 500 cast iron boiler with 9 blades

Chauffagekar cast iron boiler Super 500 9-blade is a safe choice for the production of heating water and sanitary hot water. These boilers are fully compatible with all energy management systems (BMS).

Features of Super 500 cast iron boiler with blades

- Super 500 boiler cast iron boilers are produced in the form of blades (5 to 9 blades) and Super 500 boiler cast iron boilers can work with gasoline fuel in addition to natural gas.

- The maximum working pressure in the cast iron boiler of boiler model Super 500 is equal to 4 bar and the maximum working temperature in these boilers is 90 degrees Celsius.

- Chauffagekar cast iron boiler model Super 500 has mandatory standards 4472 and 4473, European CE standard certificate, ISO 9001: 2008 quality management certificate from SGS Swiss company.

- Super 500 boilers provide a suitable solution for space heating and hot water consumption in buildings, and if a few cast iron boilers are installed, the Super 500 boiler model can increase the area used.

- Super 500 boilers take up little space in the engine room, and through single-coil and double-walled sources with dual-coil sources, the cycle can be easily coupled with a solar collector. Due to the shape of the combustion chamber and smoke passes, this boiler is compatible with all burners with suitable heat capacity.

- Installing several Super 500 boilers can increase the area used. Also, the idea of installing several boilers is one of the principles of energy optimization and always consumes less fuel than a large boiler.

- The operation of this boiler is guaranteed for 10 years, and this warranty is unconditional if installed correctly, and the damaged blades will be replaced.

- Boilers cast iron boilers model Super 500 boiler are made of refractory cast iron alloy and are resistant to oxidation and chemical agents affecting the surface, as well as environmental factors such as humidity and condensate from combustion.

- For more information to buy cast iron boiler model Super 500 Chauffagekar, click on the technical specifications on this page.

- Cast iron boilers of Chauffagekar model Super 500 boiler have high heat transfer efficiency because the body of these boilers with a thickness of 5 mm cast iron is covered by prominent fines, which increases the mechanical strength of the boiler and also increases the heat level and ultimately increases the heat transfer efficiency. The boiler is working, and the working pressure of the boiler for use in the engine room is equal to 4 atmospheres, which corresponds to the height of water up to 13 floors.

Advantages of cast iron Boilers with blades over Integrated Steel Boilers

- Suitable price and warranty for cast iron boilers compared to standard steel boilers

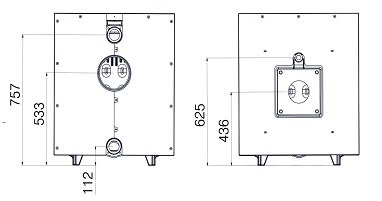

- Smaller cast iron boiler dimensions and easy transportation due to the possibility of separating the boiler blades from each other

- Possibility of replacing damaged blades of cast iron boilers and easy repair of boilers compared to integrated steel boilers

Calculation of capacity and installation of Chauffagekar super cast iron boiler

- The most important point in using cast iron boilers is the limitation of working pressure and the need to seal the bushings between the blades of the cast iron boiler after installation.

- Dimensions and price provided for the above boiler with hood are considered.

- To approximate the healing power of the cast iron boiler required, multiply the area of the useful infrastructure of the building by 150 to 200 (kcal) and obtain the heating power required for the building in kcal per hour.

Minimum equipment required for a simple engine room

- Torch (type of fuel?)

- Aquastat submerged pot

- Warm water source (coil or double-wall?)

- One-inch flange pump for warm water return

- Manometer thermometer (installed on the boiler)

- Engine room electrical panel (with at least 5 buttons)

- Expansion source (galvanized or aluminum?)

- Warm water return pump (usually linear pump "1)

- Expansion source float (with metal or plastic hub?)

- Temperature and pressure assurance valve "1 (installation on hot water source)

- Wall aquastat (operation command to the circulator pump)

- Engine room central heating boiler (cast iron boiler or steel boiler?)

- Gas burner hose and filter in the right size (or gasoline nozzle and filter for gasoline burner)

- Linear circulator pump (usually 2 inches HV or 2 inches AA or 2 inches A6 or 2 inches A7 or ... based on area)

Warranty of Chauffagekar cast iron boiler Super 500 with 9 blades

In the reference site and store of Damatajhiz, technical information and guaranteed prices of various types of cast iron boiler systems, with the main guarantee, are provided for you to enjoy a good sense of optimal and smart purchase.

Chauffagekar Super 500 cast iron boiler with 9 blades, like other products of Chauffagekar company, in addition to a 10-year warranty, enjoys the technical support and extensive after-sales service of this company throughout the country.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.