DamaTajhiz FRP Resin Softener 150,000-grain

- Working pressure: 4 bar

- Maximum capacity: 150,000

- Provide expert advice and calculations

- Manufacture of FRP (semi-automatic) resin hardeners in duplex or triplex

Guide for selecting and purchasing DamaTajhiz FRP resin softener 150,000-grain

In general, resin softeners are responsible for removing suspended mineral compounds and water-soluble salts in heating and cooling systems. Unstable calcium and magnesium ions resulting from calcium and magnesium bicarbonate salts in water, affected by the heat of water exchange to a stable precipitate of calcium carbonate and magnesium carbonate and sediments on heat exchange surfaces in heating and cooling systems.

The formation of stable sediment on the heat transfer surfaces of devices such as air conditioners and fan coils, condenser and evaporator chillers, internal surfaces of cast iron boilers, and the surface of steel boiler tubes and heat exchangers, reduces the heat exchange efficiency in these pieces of equipment. By using resin softeners by ion exchanging you can remove these destructive and harmful elements and sediments.

Resin water softeners manufactured by Damatajhiz Engineering Company are offered with excellent quality, warranty, and after-sales service of Damatajhiz in various capacities and with many features compared to similar products.

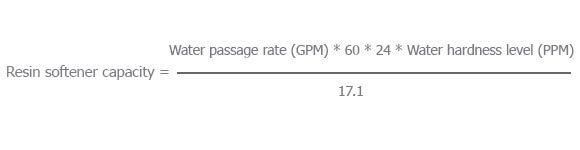

Resin softener capacity calculation formula FRP

To calculate the required capacity of different types of resin softeners, after determining the amount of water used in the project and measuring the amount of hardness of the project site (using special kits available in the market or its special tools) you can estimate the resin softener's capacity using the following formula accurately enough.

The difference between automatic and semi-automatic resin softeners

If you decided to buy water softener products and you are in doubt about the model here is the difference between automatic and semi-automatic ones:

Backwash and reduction operations in resin softeners with semi-automatic valves are performed regularly and supervised by the engine room operator and in fully automatic resin softeners without the need for an operator and based on a flow or time adjustment system automatically.

Properties of FRP resin softener 150,000 grain

The properties of resin softener are as followed:

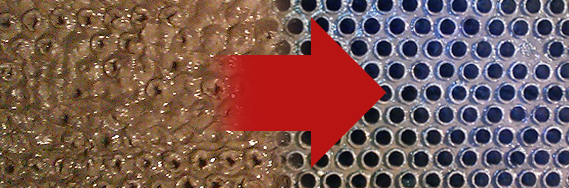

Ion exchange process

The advantage of resin softeners compared to other types of softeners is the removal of water hardness by ion-exchange process, which can be observed to reduce water hardness in this method by using hardness measuring kits, but in other types of softeners (descalers), salts It is kept suspended in water and it is not possible to remove or reduce the hardness of the water.

In heat-resistant hardeners, models with the letter P and filled with the symbol. Are softeners with British Prolite resin, which are stronger in terms of ion exchange capacity and more expensive?

Equipped with accessories

Thermosetting resin softeners, in addition to having a 3-way automatic full valve with relevant piping and nozzles made of polyvinyl (resistant to corrosion and fragility), have relevant accessories such as a salt tank, granulated silica, and resin.

Work pressure

The working pressure of the automatic resin water softener is 4 bar (bar) and the thickness of the body sheet and its upper and lower lenses are calculated and determined based on the capacity and size of the device.

Protection and standards

To protect the inner wall of the softener and the standard of the water leaving the device, the inner surfaces of the resin temperature softener are equipped with an epoxy paint coating.

Build all kinds of your orders

Damatajhiz Engineering Company can produce all your orders regarding the manufacture of various types of resin softeners in the form of duplex or triplex in compliance with all engineering principles and international standards, and after construction, to deliver the products to customers with the approval of a quality supervisor.

Purchase order and warranty of FRP resin softener 150,000 grain

- Damatajhiz 150,000 Grain FRP Softener has a 12-month golden warranty from Dama Tajhiz Company and 10 years of after-sales service.

- Damatajhiz Engineering Company has provided technical information and guaranteed prices for all types of Damatajhiz resin softeners with a golden guarantee to provide you, dear ones, with a good sense of optimal and smart purchase.

- The price of all FRP Damatajhiz resin softeners provided on the Damatajhiz reference site has been updated and the discounts desired by the esteemed employers have been included in these prices so that these prices also include the best price guarantee section of the Damatjahiz site. (Refer to the best prices guarantee section of the Damatajhiz website)

|

The following are some projects that use Damatajhiz resin softeners

- Bahman Group 2 site: Semi-automatic thermal softener with a capacity of 60,000 g

- Zarrin Nema Construction Company: Semi-automatic thermal softener with a capacity of 250,000 grains

- Fereshteh Street Terrace Park Project: 500,000 Grain Duplex resin softener

- Arman Pooyesh Abtin Project: Semi-automatic thermal resin softener with a capacity of 250,000 g

- Omid 2 project: semi-automatic heat-resistant resin softener with capacities of 1,500,000 duplex grains and 200,000 grains

- Abu Reihan Clinic Clinic: Semi-automatic resin softener with a capacity of 120,000 g

- Arsh Bana Company Made in Yazd: Semi-automatic thermal resin softener with a capacity of 600,000 g

- Soil to Allarce makers: Semi-automatic thermal resin softener with a capacity of 250,000 g

- Lean Eagle: Semi-automatic thermal softener with a capacity of 30,000 grain

- Marvdast Hospital: Semi-automatic thermal resin softener with a capacity of 60,000 g

- Azarakhsh Optimizers: Semi-automatic thermal resin softener with a capacity of 150,000 g

- General Justice of South Khorasan: Hardened resin softener with a capacity of 450,000 g

- Ekbatan Megamall Project: Semi-automatic thermal resin softener with a capacity of 1,400,000 Grain Duplex

- Pak Afarin Pooyesh Isfahan factory project: semi-automatic thermal softener with a capacity of 600,000 g (1 piece)

- Pourateb Holding Company: Semi-automatic resin softener with a capacity of 300,000 g (2 pieces)

- Chitgar Lake Frantium Project: Heat-resistant resin softener with a capacity of 1,000,000 grain double

- Sedfam Toos Company: Hard resin softener with a capacity of 120,000 g

- Madiran Company: Semi-automatic thermal softener with a capacity of 1,000,000 g

- Taleghani Hospital, Tabriz: Semi-automatic thermal resin softener with a capacity of 800,000 g

- Bo Ali University of Hamadan: Semi-automatic resin softener equipped with capacities of 90,000 -150,000 -200,000 - 40,000 - 500,000 Grain

- Razi University of Kermanshah: Semi-automatic thermal resin softener with a capacity of 30,000 g

- Ministry of Interior (Central Building): Semi-automatic thermal resin softener with capacities of 1,000,000 and 90,000

- Sina Concrete: Semi-automatic heat-resistant softener with a capacity of 150,000 g

- Dross Shahd Farin Company: Semi-automatic thermal softener with a capacity of 120,000 grain

- Rahravan Tose'e Asr Co. (Valiasr 200-unit project): Duplex resin softener equipped with a column with a capacity of 750,000 g

- Urmia Koran fish farming: Hardened resin softener with a capacity of 120,000 g

- Provincial Project (Pars Abriq Company): Hardened resin softener with a capacity of 1,200,000 Grain Duplex

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.