MI3 Iran Pipe and Machinery Cast Iron Boiler - HYPER-12

- Dimensions: 1300*1210*2338mm

- Number of Blades: 12

- Working Pressure: 8 bar

- Fuel: Natural Gas, Gasoline

- Heating Power: 825500kCal/hr

10-year Warranty

Permanent Warranty

MI3 Iran Pipe and Machinery Boiler-HYPER-12Purchasing Policy

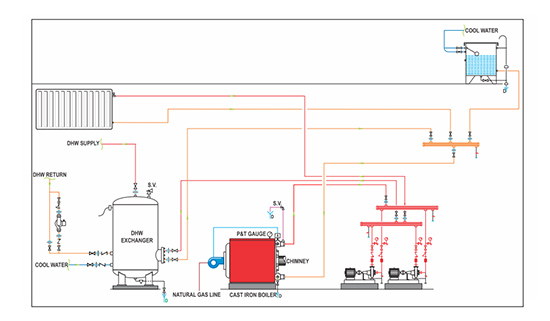

The High-Capacity MI3 Iran Pipe and Machinery Cast Iron Boiler - HYPER-12is made of the best-cast iron alloy for better heat transfer and has an efficiency of over 93%.

The high-heat capacity of MI3 Iran Pipe and Machinery Cast Iron Boiler - HYPER-12is produced by Iran Pipe and Machinery Company which has made this product suitable for use in residential houses (high-rise towers up to 27 floors and 80 meters high).

The working pressure of Hyper boilers is equal to 8 times, while this product is produced in 9 different capacities. The maximum working temperature of these boilers is 120 degrees Celsius, while these products are designed in such a way that the temperature of the exhaust gases is high efficiency, there cannot be a condensation problem in the combustion chamber.

On this site (Damatajhiz), the technical specifications and guaranteed prices of cast iron Boilers, with the main guarantee, have been provided to create a good feeling of optimal and smart purchasing for you.

HYPER - MI3 Iran Pipe and Machinery Cast Iron Boiler - HYPER-12Advantages Compared to Other Integrated Boilers in the Engine Room:

- The small dimensions and easy transportation due to the possibility of separating the boiler blades from each other

- Possibility of replacing damaged boiler blades and easy repair of boilers compared to other boilers

- Fair price and warranty of cast iron boilers compared to other standard boilers.

The Final Price of MI3 Iran Pipe and Machinery Cast Iron Boiler - HYPER-12will be announced at the time of inquiry.

The Price is affected by the Dimension and Coat of the product.

MI3 Iran Pipe and Machinery Cast Iron Boiler - HYPER-12 Capacity Calculation:

To calculate the approximate power of a cast iron boiler first, multiply the area of the useful infrastructure of the building by 100 (kcal) and then add 6000 (kcal) for each residential unit to supply the required hot water. For example, for a building with an area of 1500 square meters, useful infrastructure, and 10 apartment units, the required heating power of the boiler is (10 × 6000) + (100 × 1500) = 210,000 kCal.

To calculate the capacity of the required MI3 Iran Pipe and Machinery Cast Iron Boiler, based on the number of units, area, and type of the building, the presence or absence of a hot water pool, etc., you can consult with the experts of Damatajhiz.

To calculate the capacity of the required MI3 Iran Pipe and Machinery Cast Iron Boiler, based on the number of units, area, and type of the building, the presence or absence of a hot water pool, etc., you can consult with the experts of Damatajhiz.

Furthermore, after the mentioning calculation, add a more 20% to the calculated capacity of the engine a reliability coefficient.

The most important thing about using MI3 Iran Pipe and Machinery Cast Iron Boilers is the limitation of working pressure and the need to seal the bushing between the blades of the cast iron boiler after installation.

If the number of apartment units is more than 6, using 2 central heating boilers parallel to each other in the engine room, each of which has 70% of the required capacity, will ensure the stable supply of heating and hot water required for the building.

Installing a thermometer is required to display the hot water temperature in the boiler as well as the pressure of the building heating system on each boiler.

It is also necessary to install a submersible thermostat with a temperature range of 30 to 90° C or 30 to 110° C to adjust the boiler temperature and the turn-off and turn-on command to the burner relay.

Since the installation of all the main equipment of the engine room, including the central heating boiler on the concrete foundation has already been done with appropriate dimensions according to the location plan and exactly where the equipment is located, so before installing the main equipment of the engine room, install the required concrete foundation according to the defined dimensions and standards.

For hospital, hotel, and utility projects, it is necessary to use at least 3 central heating boilers, each of which can supply 75% of the energy required for heating the building, because even if two boilers are out of service for technical problems, it is possible to provide the necessary heating for the building with the one that is still working.

How To Increase MI3 Iran Pipe and Machinery Cast Iron Boiler - HYPER-12Lifespan

- Select the appropriate capacity of the central heating boiler for your building to provide heating and hot water to the building, even on the coldest days of the year. The central heating boiler has to work continuously and without interruption.

- Choosing the right burner with the calculated heating capacity (Maximum 20% more than the boiler capacity)

- Using a suitable resin hardener with the volume of circulating water in the heating system or setting a proper descaling on the engine room pipes.

- Accurately adjusted torch flame (blue burner and direct longitudinal flow of the burner flame in the boiler)

- The proper length of the combustion chamber of the boiler and non-permanent flame collision with the rear or middle blades of the cast iron boiler.

- Every spot of the boiler's body should be equally thick

- Proper sealing of the boiler blades during installation and not having high water pressures (caused by the intensive number of floors) on the water circulation inside the boiler.

Warranty and Originality of the Calor Steel Water Boilers :

10 years warranty and After-Sale Service of MI3 Iran Pipe and Machinery Cast Iron Boiler - HYPER-12.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.