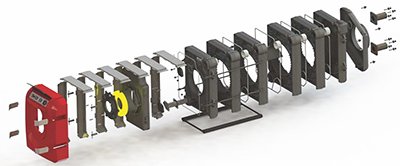

Chauffagekar Superheat 400 10-Blade Cast Iron Boiler

- Heating energy: 258000 kcal/h

- Boiler dimensions (length, width, height): 1503*630*774 mm

- Number of blades: 10

- Working pressure: 4 bar

- Fuel type: natural gas or gasoline

10 Years Warranty

10 years

Selection and Purchase Guide for Chauffagekar Super 400-10 Cast-Iron Boiler

The Chauffagekar Super 400-10 cast iron boiler, produced and marketed by Chauffagekar since 2001 as the best-selling cast-iron boiler in the country, is widely renowned for its high thermal efficiency as well as small dimensions.

Features of the Chauffagekar Super 400-10 Cast-Iron Boiler

- Mandatory standards of 4472 and 4473, CE European standard certificate, SGS ISO 9001:2008 quality management certificate.

- Easy boiler transportation due to its single-blade design and the ability to separate the boiler’s blades,

- Easy boiler repair compared to other steel boilers due to the ability to change the boiler’s damaged blades.

- Cast-iron boilers have better warranties and more affordable prices than steel boilers,

- While using cast-iron boilers, it is important to limit workload and to perform socket break-ins between boiler blades after installation.

- The Chauffagekar Super 400-10 is made of flame-retardant cast-iron alloy and produced as separate blades. It is resistant to oxidization, chemical agents effective against surfaces, and environmental agents like humidity and combustion condensates.

- The Chauffagekar Super 400-10 cast-iron boiler is designed to increase heat transfer efficiency while reducing boiler dimensions. It can sustain a 4-bar workload and 105-degree centigrade operation temperature, which makes it suitable for installation and use in up to 10 store buildings. In Chauffagekar boilers, the casting-iron width of every blade, according to the announcement made by Chauffagekar, is approximately 6 mm.

- In addition to producing hot water for building heating systems and hot sanitary water in central heating rooms, the Chauffagekar Super 400-10 cast-iron boiler is compatible with all energy management systems (BMS) that are required for feeding single-effect absorption chillers. Also, according to the table and engineering standards, to supply hot water for heating systems and consume sanitary hot water used in large buildings, several central heating boilers should be used in parallel.

- Suppose the number of apartments is more than 6. In that case, two parallel central heating boilers that each have 70 percent of the required heating capacity will ensure a stable heating and hot water supply for consumption in the building.

Notes for optimizing energy consumption while using Chauffagekar Super 400-10 cast-iron boilers in the boiler room

- Checking the resin or magnetic water softener installed in the boiler room every month,

- Checking cast-iron boilers each year for desalination

- Checking and cleaning surfaces that have been exposed to fire and smoke

Calculating capacity and installing Chauffagekar Super 400-10 cast-iron boiler

- To calculate the approximate required power, first, multiply the effective built-up area by 100 (kilocalories) and then add 6000 (kilocalories) for each residential unit for supplying hot consumption water. For example, for a building with a 1500 cubic meter built-up area having 10 apartments, the amount of boiler heating power required is as follows: (1500×100)+(6000×10)=210000. After calculating the figure above, up to 20 percent is usually added to the calculated capacity of the heating room hot water boiler as a confidence coefficient.

- To calculate the required capacity of the hot water cast-iron boiler according to the number of residential units, area, building use class, the existence or absence of warm water pools, etc., you can consult with the Damatajhiz company experts.

- Any changes to the final price of the Chauffagekar Super 400-10 cast-iron boiler will be announced at the time of making the purchase inquiry.

- Dimensions and prices presented above for the Chauffagekar hot water cast-iron boilers include the cover.

- Installing a thermometer monometer to display the boiler water temperature and also the building’s central heating system pressure for each cast-iron heater in the heating room is mandatory.

- Installing submerged thermostats (submerged aquastats) with a temperature range of 30 to 90 degrees centigrade (or 30 to 110 degrees centigrade) to adjust boiler temperature and issue on-off commands to the flame relay on each cast-iron heater is also mandatory.

- Since all main heating room equipment, including the central heating boiler, are installed on the concrete foundation that is previously built-in suitable dimensions in the precise location of equipment according to the layout plan, make the necessary preparations concerning the required concrete foundation according to the specified dimensions and standards before installing the main heating room equipment including the cast-iron boiler.

To see more models and buy cast iron boiler products in other capacities, click on the link.

The Chauffagekar Super 400-10 Cast-Iron Boiler Warranty

In addition to a 10-year warranty, the Chauffagekar Super 400-10 cast iron boiler, like other Chauffagekar products, has widely available technical support and after-sale services.

Technical information and guaranteed prices for a variety of Chauffagekar Super 400-10 cast-iron boilers, including the original warranty, are provided to our dear customers on the main Damatajhiz website and stored for a smart and efficient purchasing experience.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.