Alfa Laval Plate Heat Exchanger CBH16-35H

- SS.316 stainless steel body

- Working pressure: 20 bar

- Thermal energy: 80,000 kcal/h

- Inlet and outlet pipe size: 3/4 cold side

- Inlet and outlet pipe size: 3/4 warm side

1 Year Warranty

10 years

Guide to choosing and buying Alfa Laval plate heat exchanger model CBH16-35H

Alfa Laval is a Swedish technical and engineering services company, which was founded by Oscar Lamm and Gustaf de Laval in 1883. This company, which was established in the beginning of its activity in a branch different from what it operates today, is currently engaged in the production of specialized-industrial equipment, as well as the production of parts and accessories needed in heavy industries, as well as the supply of these products in the market. Industries operate.

Mr. de Laval started the establishment of this company by building the first continuous separator with a capacity of 130 liters per minute in 1879, which is engaged in the production and sale of centrifugal pumps, pasteurizers, heat exchangers, separators, flow transfer valves, etc. He gained world fame. Alfa Laval produced the first milk pasteurizer in 1890. This company introduced its first heat exchanger to the world in 1931.

Features of Alfa Laval plate heat exchanger model CBH16-35H

Work efficiency and work pressure

Alfa Laval plate heat exchanger, model CBH16-35H, with a working pressure of at least 15 bar and a maximum of 40 bar (in different models, the working pressure is different) and with very high efficiency, provides immediate and hygienic hot water at the lowest cost and without wasting energy. does Keep in mind that if a heat exchanger is used to produce a sanitary spa for residential units, 300 to 400 liters of exchanger capacity is required for each unit.

-

Also, in case of using Alfa Laval plate heat exchanger model CBH16-35H in underfloor heating systems, for each meter of PEX pipe length worked in the floor, about 136 kilocalories of heating capacity should be considered for choosing the required heat exchanger.

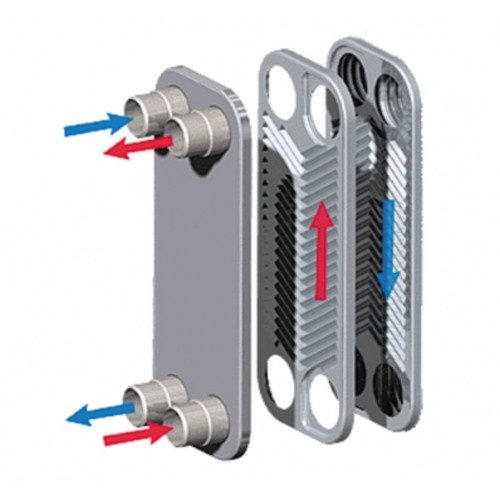

- Alfa Laval plate heat exchanger model CBH16-35H can be used for liquid-to-liquid, steam-to-liquid and gas-to-liquid systems and it is very small in size and occupies little space compared to its high operational efficiency.

- The type of design of Alfa Laval plate heat exchanger model CBH16-35H is such that it optimizes heat transfer by creating turbulence in the fluids and causes self-cleaning of the exchanger.

- The welding of plates of Alfa Laval plate heat exchanger model CBH16-35H is done in vacuum conditions, which makes it strong at high pressure and operating temperature, and also allows the connection of two balanced plates at thousands of points and a significant increase in the efficiency of the converter.

- The material of all Alfa Laval plate heat exchanger plates is stainless steel (SS316) and in Alfa Laval exchangers, the models that start with CB represent copper brazed plate heat exchangers.

- The quality and efficiency of Alfa Laval plate heat exchangers are such that 65% of the world market share of plate heat exchangers is owned by Alfa Laval company.

- Alfa Laval plate heat exchanger model required for special conditions based on the type of fluids involved in the process, the pressure and temperature of both sides and the flow rate of the consumed fluid are calculated through CAS software of Alfa Laval company and if necessary, the technical specifications of the process with Alfa Laval header is available.

- Alfa Laval company is the exclusive manufacturer of welded steel converters (Alfa Nova) with the abbreviation (AN) which are used for special purposes that require the use of all steel materials in the equipment used in the production process.

Important points when installing the Alfa Laval CBH16-35H plate heat exchanger

- The use of suitable hardness and smoothness is necessary to increase the useful life of Alfa Laval plate heat exchanger model CBH16-35H and other equipment involved in the temperature transfer process.

- In addition to the necessity of installing a hardener in the water path of the heat exchangers, which has already been mentioned, it is necessary to install the spool nut and the valve on all the water pipes entering and leaving the heat exchangers in order to perform periodical services and acid washing. .

- Due to the necessity of using a one-way valve + two strainers (filters) as well as a linear stiffener (magnetic, electronic, etc.) during the installation and operation of all types of plate heat exchangers, in the absence of necessary In the above project, at the same time as buying the heat exchanger, order the purchase of these accessories, according to the size of the inlet and outlet pipes.

Alfa Laval CBH16-35H plate heat exchanger warranty

Alfa Laval plate heat exchanger model CBH16-35H on Damatajhiz site has a warranty card from the official representative of Alfa Laval company with a serial number of the converter with a 1-year warranty and 10 years after-sales service (if non-standard acid washing of the converter is not performed).

Alfa Laval company with 120 years of experience in producing the highest quality and most efficient plate heat exchangers has 28 production centers around the world and the plate heat exchangers are supplied by the official representative of Alfa Laval company in Iran, directly from Alfa Laval company. are supplied in Sweden.

To see more information and models and prices of heat exchangers you can click on the linked words.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.