Purchasing Guide for Alfa Laval Plate Heat Exchanger

- Alfa Laval Company by having 120 years of experience in the field of production of the best quality and the most effective plate heat exchangers has 28 production centers throughout the world and plate heat exchangers supplied by official agent of Alfa Laval Company in Iran are directly supplied by Alfa Laval Company in Sweden.

- Quality and efficacy of Alfa Laval plate heat exchangers has been excellent enough to attract 65% of the market share of the world plate heating exchangers for Alfa Laval Company.

- Working Pressure of Alfa Laval Heat Exchangers are equal to 15-40 Bar.

- All Alfa Laval welded plate heat exchangers represented at site of DamaTajhiz are provided with warranty card of the official agent of Alfa Laval Company by inserting serial No. of the exchanger for 1-year warranty and 15 years of after-sale-services (in case of non-standard pickling).

- Alfa Laval plate heat exchangers are made of steel stainless SS316 and Alfa Laval exchangers which are started from CB indicates plate heating exchangers with copper brazed

- Alfa Laval Company is also an exclusive producer of (Alfa Nova) steel weld exchangers with abbreviated sign (AN) which has been used where the use of all steel materials in equipment operating in the processes is necessary.

- Welding of plates of Alfa Laval Plate Heat Exchangers is done in vacuum conditions which causes its consistency in high operational pressure and temperature and provides the ground for communication of two balanced plates in thousands of points and remarkable increase of the exchanger performance input.

- Alfa Laval Plate Heat Exchangers supplies urgent and healthy consumable hot water with the lowest expense and without energy waste by 10-bar work pressure and high efficiency and in case of use of heating exchanger for production of healthy hot water of residential units, consider 300 liters of exchanger per unit.

- In case of use of plate heat exchanger in under floor heating systems, consider about 136 kilocalories of heating capacity for selection of required heat exchanger per meter length of PEX pipe installed in the floor.

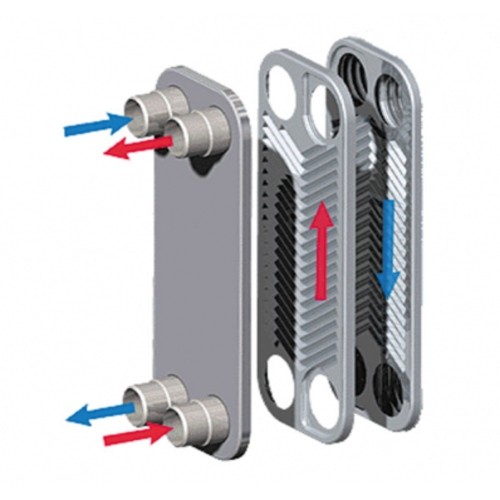

- These systems can be used for liquid to liquid, steam to liquid and gas to liquid systems and in spite of having high productivity are very low volume and occupies low space.

- Alfa Laval Plate Heat Exchangers are designed in such a way that optimizes heat transfer by turbulence in floods and causes self-cleaning of the exchanger.

- Model of plate heat exchanger required for special conditions have been based on type of floods involving in the process, pressure and temperature of both sides and flow rate of consumable flood, via CAS software of Alfa Laval Co. and if required, technical specifications of the process are presented by head letter of Alfa Laval.

- Using suitable softener and filter for increase of long life of the plate heat exchanger and other equipment involving in temperature transfer process is obligatory.

The points should be taken into consideration after purchasing Alfa Laval Plate Heat Exchangers

- In most cases, input and outputs of fluids to the exchanger should be determined in such a way that two fluids inside the exchanger flow in a counter current form to reach the most operational efficiency.

- In piping systems, it is possible to install the small exchangers on the baseless line. But when large exchanges are used, it is necessary to use suitable bases to prevent from vibration.

- It should be noted that the exchanger should be far from any kind of welding heat while installation. For this purpose, the exchanger may be wrapped in a moisture towel.

- Temperature sensor should be installed in the exchanger output and as much as possible nears the output on the pipe.

- It should be noted that irrupt temperature changes cause exertion of very high pressure on the exchanger and fatigue of the exchanger, as a result, use of current and temperature adjustment instrument increases ex changer's life.

- Adjustment of current for keeping a temperature stable or having proper pressure loss should be done slowly to prevent from system shock.

- To get assured of correct performance of the exchanger, you are recommended to use current control valves and temperature and pressure gauges both sides of exchanger.

- For correct washing of the exchanger on the site, contact Company supplying the exchanger.

- Improper washing of the exchangers may result to appear the hole in exchanger plates and it is irrevocable damage and is not covered by the warranty.

Fast shipping nationwide

Secure payment

Valid warranty

After-sales service

Address

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

Phone

Fax

Email

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.