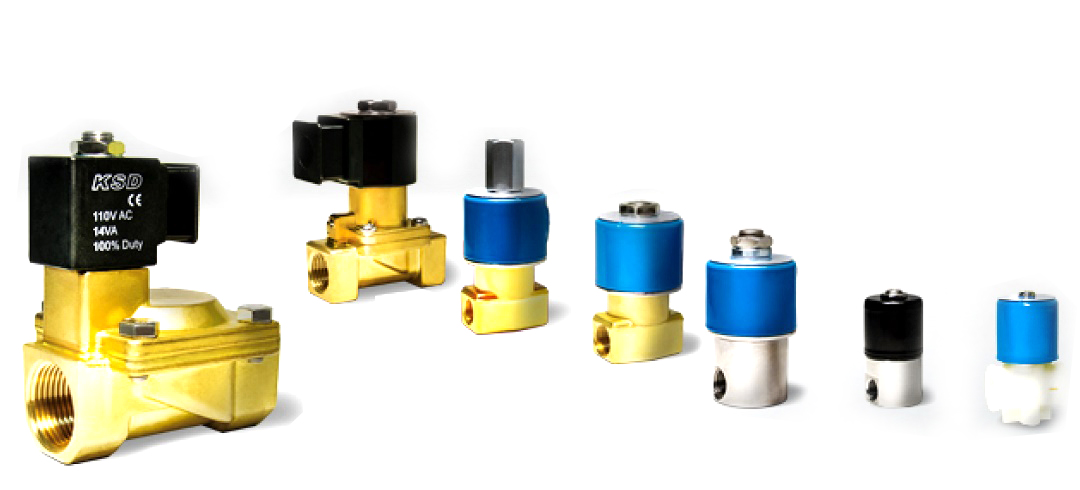

Electric Solenoid valve

As you know, the main prerequisite for doing any work is to have correct information about that subject. Regarding selection, checking the prices, buying, and getting to know more about the types of electric valves, the contents are listed below so that you, dear visitors of the specialized website of the Damatajhiz collection (an official member of the heating and air conditioning equipment sellers' union), with the help of these tips, can Sufficient information, choose and buy electric valves suitable for your living or work environment in bulk.

Choosing and buying electric solenoid valves

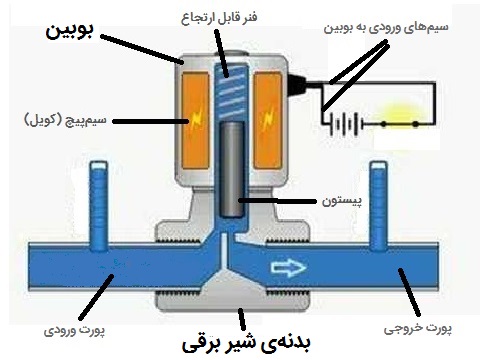

An electric valve is a valve that operates by electricity and magnetic force. A solenoid valve is a coil wrapped around an iron core, and when the electric current passes through it, it produces a magnetic field and causes the core to move linearly. Therefore, the solenoid valve converts electrical energy into linear motion. An electric valve is a device used to control fluids such as gases and liquids. Some electric valves can open or close from 0 to 100% by receiving an electric command, which is very important in automatic and industrial machines. Join us in introducing and checking the performance of different types of solenoid valves in the rest of this article.

Types of electric valves

Direct motion solenoid valves: These are divided into two types, normally open and normally closed

Servo solenoid valve: these solenoid valves can be completely open or closed based on the pressure difference in the diaphragm, even when the fluid flow is interrupted.

Solenoid valve NC (Normally closed)

NC, or normally closed solenoid valve, cuts off the fluid flow when the electricity is cut off and when the current is reconnected, the valve opens and allows the fluid to flow.

Solenoid valve NO (Normally Open)

These solenoid valves allow fluid flow when the current is cut off, and when the electricity is connected, the flow path of the solenoid valve is closed and does not allow the fluid to pass.

Solenoid valve components

- body

- Fluid inlet

- fluid outlet

- Rewind

- Coil frame

- Connecting the wires

- metal bar

- spring

- outlet valve

Maximum working pressure or MWP

The maximum working pressure (MWP) is equal to the maximum working pressure of the system to operate the valve or system components without damage.

The maximum opening pressure difference (MAXODP)

The maximum opening pressure difference (MAXODP) equals the maximum pressure difference the valve can open in this state.

Alternating current solenoid valves usually have a higher working pressure.

Minimum working pressure difference or (MINOPD)

The minimum working pressure difference (MINOPD) equals the pressure required to open the solenoid valve. When this pressure is too low, the diaphragm or piston of the solenoid valve cannot remain open.

Solenoid valve capacity

The capacity of the solenoid valve is expressed in the VK unit, and it expresses the amount of water flow (based on cubic meters per hour) with a pressure drop of 1 bar in the solenoid valve.

Essential points in choosing a solenoid valve

- Current and voltage

- Voltage type

- Maximum time on

- type of milk

- Opening size

- The amount of pressure

- Fluid and environment in which the valve can work

- Connection type for each device

In the following, we will introduce some of the commonly used types of solenoid valves in facilities:

- Electric water valve

- Gas solenoid valve

- Steam solenoid valve

- Diesel solenoid valve

- 2-way solenoid valve

- Three-way solenoid valve

Diesel solenoid valve

The diesel solenoid valve is used to pass fuel from the pump to the diesel nozzle. This causes that when the burner is turned off, diesel does not leak into the combustion chamber. When the burner is started, fuel is sprayed for about 15 seconds, the anti-generator is activated, and the air inside the boiler is removed. During this time, the diesel route must be closed, and an electric valve does this.

Gas solenoid valve

In devices that use gas fuel, there is always a risk of explosion. For example, the burner of the engine house uses a solid spark to ignite the gas, which can cause an explosion due to the gas's high pressure and the burner's vital spark. To prevent this explosion, they use a variety of pilot, gradual, and safety solenoid valves in the burner fuel path.

The function of the gas solenoid valve is that the solenoid valve operates in two stages. First, the solenoid valve is half open in the first stage, and it enters the gas with a slight pressure into the burner; after the burner is turned on, the solenoid valve is fully opened, and the gas enters the burner ultimately. These solenoid valves have a primary gas pressure adjustment screw.

Electric water valve

The water solenoid valve controls the flow of water inside the pipe and the electric current. To function (open and close), the electric water valve needs initial pressure inside the pipe (for example, at least 0.5 mbar for small valves). Water solenoid valves are used in various industries, agriculture, domestic use, etc., such as turning off and on the flow, combining two flows, drip irrigation, fogging, etc. In case of failure, it is possible to replace the defective part (such as a bobbin or solenoid) to There is simplicity.

Buying electric solenoid valves

In the specialized HVAC group of Damatajhiz, all the electric solenoid valves are only sold in bulk. Therefore, if you want to wholesale any of these products, feel free to contact us.

The effect of a solenoid valve on energy loss

Standard valves used in engine houses are usually opened or closed based on the type of operation when necessary. After some time, due to fluid deposits, air humidity, dryness of the valves, etc., they are entirely open or not closed. In environments like the engine room, they cause loss of fluid energy or the heat of the water in the engine room. To prevent the problem, an electric valve is used.

Failure factors in solenoid valves

- Lack of alignment and lubrication prevents fluid transfer.

- Use of improper voltage

- Broken parts such as hinges or levers

- Repetitive disconnection and disconnection of the electric valve and its heating

- Breaking the electrical clamp or cutting the electrical current connection wire

- Solenoid valve leakage is due to factors such as mass, garbage, scratched seats, torn seals, lack of or inappropriate lubrication, heat, and humidity.

- Cap is not in place

Advantages of solenoid valves

- Easy installation

- Installation in dangerous places with chemical vapors or explosive or scorching environments

- Shortening the piping path and easier fluid discharge from the pipeline

- Ability to control remotely or from the control room

- High safety

- energy saving

In the electric valve group, the reference website, and the store of Damatajhiz, see the information and prices of all kinds of electric valves for water, steam, gas, etc., from the brands of Danfoss, Dongs, Parker, Unidi, etc., for review and selection.

In addition to a valid business license from the heating and air-conditioning trade union, Damatajhiz has an electronic trust symbol. It started operating its store site in 2013 in Tehran's head office.

See more, and choose smarter.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.