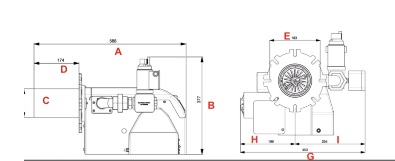

Chauffagekar Gas-fuel Burner CKI-G260

- Maximum heating power: 225.000 Kw/hr

- Fuel consumption: natural gas

- Combustion mode: single stage

- Power consumption: single phase

- Flame tube diameter: 112 mm

Warranty :

1 year Iran Radiator warrantyAfter-sale Services :

10 yearsGuide to Choose and Buy Chauffagekar Gas-fuel Boiler Burner CKI-G260

The Chauffagekar Gas-fuel Boiler Burner CKI-G260 is a device that converts fossil fuel energy into heat energy by combining fuel and air and combustion of this mixture. The Chauffagekar Gas-fuel Boiler Burner CKI-G260 has a maximum heat capacity of 206,000 kcal per hour. Chauffagekar Company is one of the most well-known brands active in the production and supply of heating equipment in the country's industries and exports to all parts of the world. In previous years, cast iron boilers were offered alone, with buyers providing separate boiler burners to equip their boilers for use. Incorrectly choosing two related products would fail the boiler, burner, or both. To solve this problem, Chauffagekar Industrial Company chose the standard of the boiler along with the boiler burner and offered two products at the same time. Benefits of choosing a standard boiler and boiler burner include reducing combustion pollutants, increasing thermal efficiency and reducing energy consumption.

Features of Chauffagekar Gas-fuel Boiler Burner CKI-G260

- When choosing a Chauffagekar Gas-fuel Boiler Burner CKI-G260, pay full attention to the diameter of the flame tube to allow the pipe to enter the boiler and install the boiler burner.

- In general, when using the Chauffagekar Gas-fuel Boiler Burner CKI-G260 and the need to pay attention to the type of boiler burner fuel, various reasons must consider the capacity of the boiler burner about 20% more than the capacity of the boiler or heater combustion chamber.

- Suppose the gas line pressure of the boiler burner is 2 pounds. In that case, it is necessary to use a balancer to adjust and balance the small changes in gas pressure of the gas boiler burner supply with the required size and flow of the boiler burner gas at the beginning of the gas line. Also, suppose the gas supply pressure of the boiler burner is higher than 2 pounds (15 or 30 to a maximum of 60 pounds). In that case, it is necessary to install a gas regulator with the appropriate size, working pressure and gas flow at the beginning of the boiler burner gas line.

- Installing a gas filter with the appropriate size and working pressure after the gas quarter round valve and before the gas regulator and shock or solenoid valve gas valves is one of the first pieces of equipment required for the gas line in gas boiler burners.

- It has an integrated body.

- It has an engine speed of 2800 RPM

- It is a single-stage combustion method.

- No electrical panel

- It has a control roller, manual air damper, solenoid valve, air and gas pressure.

- It has a flame monitoring system of the ionization rod type

- The above gas boiler burner is suitable for boiler boilers model Super 400-8 to 11 blades, Super 7-5 to 8 blades, Solar 10-10 to 13 blades and Turbo 8 blades.

Performance of Chauffagekar Gas-fuel Boiler Burner CKI-G260

- The inlet airflow is manually controlled by an air damper installed in the burner body based on its capacity.

- Gas burners can be classified into those that have a blower or fan and others without one (without sound). The burners used in apartment packages are of the kind of gas burner without blower and sound.

- The gas burner is designed to combustion natural gas, and the gas required for combustion in these burners, after passing through the gas filter, is controlled by a solenoid valve. A blower installed on the engine shaft supplies the necessary air for their combustion.

- The gas stream passes through a filter, mixes with the combustion air and is ready for combustion. If the combustion air pressure is too low or the gas pressure is too high or too low, this is sensed by the built-in pressure sensors and the burner is switched off by the force of the air and gas switches via the relay command.

Adjusting the Chauffagekar Gas-fuel Boiler Burner CKI-G260

Complete combustion of the fuel is the result of fine-tuning the fuel-air ratio. The more precisely this ratio is adjusted, the higher the combustion efficiency and therefore, less energy is required. In small boiler burners, the air adjustment needed for combustion of the boiler burner is made by a manual damper. Still, this adjustment is provided by an automatic damper for the required combustion air in large boiler burners. However, because the engine room boiler's air temperature and humidity vary throughout the year, the air damper must be readjusted each season in large boiler burners. Today, modern boiler burners have an intelligent PLC control system that automatically adjusts the ratio between fuel and air throughout the day and all seasons.

Due to the incompleteness of fuel combustion efficiency in boiler burners and considering some heat losses, when choosing a boiler burner, we think the boiler burner capacity should be about 20% more than the boiler capacity.

- The calorific value of each litre of diesel is approximately equal to 8500 K.cal.

- The calorific value of each kilogram of diesel is approximately equal to 10500 K.cal.

- The calorific value of each cubic meter of natural gas is approximately equal to 9200 K.cal.

- In general, the fuel combustion efficiency of all boiler burners drops by about 4% for every 300 meters increase in height from the door's surface or due to a decrease in air concentration.

Warranty of Chauffagekar Gas-fuel Boiler Burner CKI-G260

The Chauffagekar Gas-fuel Boiler Burner CKI-G260 has a 1-year warranty from the Chauffagekar company.

Visit the Damatajhiz website for more information and to buy burners.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.