DamaTajhiz Semi-Automatic 150000 Grain Metal Resin Water Softener

- Working pressure: 4 bar

- Dimensions (height, diameter): 150 * 45 cm

- Can be ordered in two types with aqualite or purolite resin

- Manufacture of various types of resin hardeners in the form of duplex or triplex, covering the inner surface with epoxy paint

- Contains accessories such as salt tank, granulated silica, pressure gauge

✔️ Pre-Sales Services:

- Flexible payment options + Standard installation services

- Engineering consultation + Expert calculations and capacity sizing

![]() Delivery Time: 4 working days (coordinated with sales experts)

Delivery Time: 4 working days (coordinated with sales experts)

DamaTajhiz Semi-Automatic Metal Resin Water Softener Selecting and Purchasing Guide

The 150,000-grain semi-automatic metal resin water softener is designed to remove suspended minerals and dissolved salts from the water used in building heating and cooling systems.

Unstable calcium and magnesium ions, which originate from calcium and magnesium bicarbonates in the water, convert into stable calcium carbonate and magnesium carbonate deposits under heat. These deposits form on heat exchange surfaces in HVAC systems. Such scaling in components like air handler and fan coil coils, chiller condensers and evaporators, internal surfaces of cast iron boilers, steel boiler tubes, and heat exchangers reduces thermal efficiency. Therefore, using resin or ion-exchange softeners is essential to eliminate these harmful deposits before they accumulate.

This semi-automatic resin water softener, manufactured by DamaTajhiz Engineering Co., is offered in various capacities and configurations, with outstanding quality, premium warranty, and after-sales support, standing out among similar products.

DamaTajhiz — Thousands of Products for Thousands of Projects (Since 2004)

Key Considerations When Buying the 150,000-Grain Semi-Automatic Resin Water Softener

- The most important factor in properly using semi-automatic resin softeners is regular maintenance and periodic backwash operations by a trained operator.

- One of the key responsibilities of a boiler room technician is to perform regular backwash operations (removing water hardness and deposits) on semi-automatic softeners. This should be done consistently based on the instructions provided below. Failure to perform regular backwash leads to salt and mineral buildup inside the unit, eventually causing the softener to stop functioning.

Difference Between Automatic and Semi-Automatic Resin Softeners

Backwash and regeneration in softeners with semi-automatic valves must be done manually and on a set schedule by the operator. In contrast, fully automatic softeners perform these tasks without operator intervention, based on preset flow or time settings.

Formula for Calculating Water Softener Capacity

Required Water Softener Capacity (in grains) = (Water Hardness in PPM) × (Water Flow Rate in GPM) × 60 × 24 ÷ 17.1

To calculate the required capacity of resin softeners, measure the project’s water consumption and the hardness level (using test kits or measuring devices), then apply the above formula for accurate sizing.

Features of Semi-Automatic Resin Water Softeners

- Ion Exchange Process

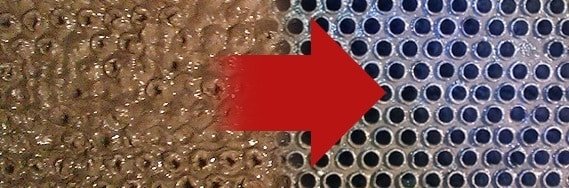

Unlike other types of softeners, resin softeners eliminate hardness through ion exchange, which can be verified using hardness test kits. In contrast, descalers only keep minerals suspended without actually removing them.

DamaTajhiz models marked with "P" are filled with premium Purolite resin from the UK, offering higher exchange capacity and a higher price. - Comes with Essential Accessories

All DamaTajhiz resin softeners include a 3-way semi-automatic valve, related piping, corrosion-resistant polyvinyl nozzles, and essential accessories like a brine tank, graded silica, pressure gauge, and resin. - Operating Pressure

The 150,000-grain semi-automatic resin softener from DamaTajhiz operates at 4 bar. The tank body and dish head thicknesses are engineered based on the device’s capacity and size. - Coating and Standards

To protect the internal surface of the water softener and meet output water standards, internal surfaces are coated with epoxy paint. - Custom Manufacturing Available

DamaTajhiz Engineering Co. also manufactures duplex and even triplex resin softeners based on customer specifications and engineering standards.

DamaTajhiz – Thousands of Products for Thousands of Projects (Since 2004)

DamaTajhiz Resin Water Softener Startup Instructions

- First, place the resin water softener on a proper foundation and connect the piping according to the previous page instructions.

- Next, open the bottom flange and gently pour the coarse silica onto the nozzle plate inside the unit. (Be careful not to damage the nozzles.)

- Level the silica surface, then tightly close and seal the bottom flange. Now open the top flange and pour the finer silica on top of the coarse layer inside the unit.

- Empty the resin bags completely on top of the silica in the softener, then firmly close and seal the top flange.

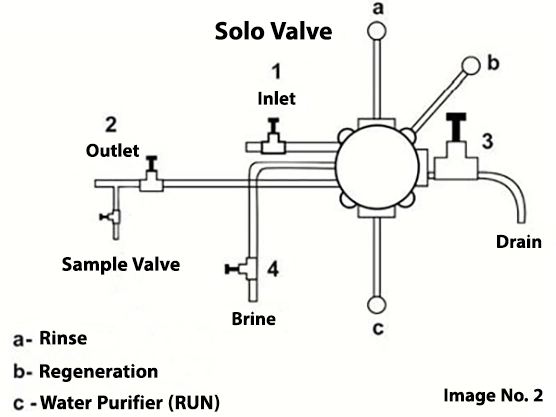

- Set the multiport valve lever to position 3 (RUN), close valve No. 2 (outlet), and open valve No. 4 (drain) and valve No. 1 (inlet) for 5 minutes to rinse the silica.

- Then close valve No. 4 (drain) and set the multiport valve to position 1 (WASH) for 10 minutes to rinse the resin.

- Set the multiport valve back to position 3 (RUN), and bleed the air from the softener using valve No. 6.

- By opening valve No. 2 (outlet), the water softener is now ready for operation. (Add salt and water into the brine tank to prepare the unit for regeneration.)

Important Tips for Operating DamaTajhiz Resin Water Softeners

- The hardness of the outlet water from the DamaTajhiz 150,000-grain semi-automatic resin softener must always be checked using a hardness test kit through the sampling valve. If the hardness exceeds the acceptable level, the operator must perform resin regeneration immediately.

- During resin regeneration, make sure the tank pressure is between 1.7 and 3.5 bar. Low pressure may disrupt brine suction, and high pressure could damage the multiport valve components.

- For pressures above 4.5 bar, it is recommended to install a pressure regulator before the valve, or at least close valve No. 1 (inlet) while switching the multiport valve positions to avoid sudden pressure surges.

- Always use high-purity crystallized salt. Using rock salt or regular table salt can reduce the resin's lifespan due to impurities and lead to incomplete regeneration.

- The brine suction rate is factory-set, but can be adjusted near the brine pipe behind the valve if needed. Suction must ensure about 10% brine concentration for proper regeneration. A reduction in suction may be due to low pressure or blockage in the brine line.

- Avoid using turbid water or water containing suspended particles, iron, manganese, copper, or other heavy metals, as these can degrade the resin and reduce the unit’s efficiency. It is advisable to use a sand filter before the water softener.

- When turning the multiport valve handle, gently pull it toward yourself and place it in the desired position. Sudden release may damage the valve’s internal parts.

- It is recommended to lubricate the multiport valve once a year using regular grease through the gap between the cap and the valve body without disassembling the valve.

- Protect the resin and water inside the softener from freezing. Freezing can destroy the resin completely.

Startup & Installation of Semi-Automatic Metal Tank Resin Water Softeners

DamaTajhiz resin water softeners use chemical water treatment and special resins (anionic or cationic) based on customer requirements to provide completely softened water at low operating cost for HVAC and industrial applications such as steam boilers, steel and cast iron boilers, cooling towers, and more. These softeners operate semi-automatically and their startup procedure is described above.

Preliminary Steps Before Starting Up the Softener After Installation

- Connect the inlet and outlet water pipes of the unit to the system.

- After opening the inspection port (top flange), fill the tank with silica and either cationic or anionic resin as required, then firmly close the flange using a star pattern method.

- Place the salt tank (containing a properly concentrated water-salt solution—250 grams of salt per liter of resin) underneath the brine line of the softener.

Startup Instructions for Semi-Automatic Metal Tank Resin Softener by DamaTajhiz

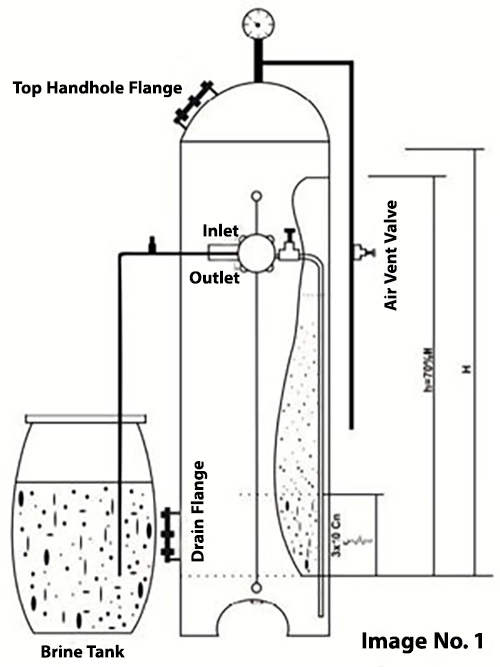

- First, close all valves and open the air release valve on the unit. (Image 1)

- Turn the Solo valve handle to the "Run" position.

- Open valve No. 1 in Image 2 (inlet). The tank will begin to fill with water gradually.

- Once water starts to come out of the air vent, close the air vent valve.

- Open valve No. 2 in Image 2 (outlet). The system is now ready for operation and water softening.

- Note 1: During operation, ensure that the internal pressure of the softener tank stays between 1.7 and 2.5 bar (check the pressure gauge on the unit).

- If the pressure is below 1.7 bar, there will be issues with sealing the Solo valve and drawing in brine. If it exceeds 6 bar, components of the Solo valve may get damaged.

- Note 2: Never operate the Solo valve under pressures higher than 2.5 bar.

- Note 3: Always check the hardness of the treated water using a test kit. As soon as the hardness exceeds the permissible level, start the resin regeneration process as described below. On average, this process should be performed every 2 weeks by the boiler room operator.

How to Regenerate the Resin in the Softener

- First, close valves No. 1-2-3-4 shown in Image 2.

- Set the Solo valve handle to the "Regen" position.

- Open valves No. 3 and 4 to let the saltwater solution flow into the system. If you remove the cap over the salt nozzle (located behind the Solo valve next to the drain line), you can adjust the suction using a suitable screwdriver. (Some water will be drained and replaced with brine.)

- After the appropriate time has passed, proceed to the next step: rinsing the resin with fresh water.

Rinsing the Resin with Water

- First, close all valves.

- Turn the Solo valve to the "Wash" position.

- Open valves No. 1 and 3 (inlet and drain). Water will now enter from the bottom of the resin column and exit from the top.

- Wait for about 20 minutes to allow complete rinsing of the resin and removal of any remaining salt solution.

- Close all valves, then open valve No. 1 (inlet) of the resin softener.

- Finally, return the Solo valve handle to the "Run" position. The system is now ready for operation again.

DamaTajhiz – Thousands of Products for Thousands of Projects (Since 2004)

Order & Warranty for DamaTajhiz 150,000 Grain Semi-Automatic Metal Resin Water Softener

- The DamaTajhiz 150,000 grain semi-automatic metal resin water softener comes with a one-year exclusive DamaTajhiz Golden Warranty.

- DamaTajhiz Engineering Company provides complete technical details and the best price for buying DamaTajhiz resin water softeners, along with a golden warranty to ensure you enjoy a smart and optimal purchase.

- The prices for all semi-automatic resin water softeners listed on the specialized DamaTajhiz platform are updated and include applicable discounts for our valued clients. These prices are also covered by DamaTajhiz's Best Price Guarantee policy.

|

|

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.