Hepaco Plate Heat Exchanger HP-250

- SS.316 stainless steel body

- Working pressure: 30 bar

- Thermal energy: 125,000 kcal/hr

- Inlet and outlet pipe size: Cold side 1

- Inlet and outlet pipe size:1 1/4 warm side

HEPACO Plate Heat Exchanger HP-250

HEPACO plate heat exchanger HP-250 provides immediate consumption and sanitary warm water with the minimum cost and without wasting energy with an efficiency of over 95 percent. To calculate the approximate plate heat exchanger’s capacity for supplying sanitary water of residential units, consider 300 to 400 liters of heat exchanger capacity per unit.

Some of the most important specifications of the HEPACO heat exchanger HP-250 include Material, working efficiency, and working pressure

- HEPACO plate heat exchanger HP-250 is integrated, water to water, gas to water, steam to water, oil to water type, etc.

- HEPACO plate heat exchanger HP-250 is fabricated from stainless steel S.S.316.

- To exploit the maximum capacity of the HEPACO heat exchanger HP-250, it is recommended to convey the fluids in parallel mode and in form of Counter Flow.

- Due to the thermal capacity of the warm water or hot water boiler and heat exchanger selection in order access to adequate amounts of warm water for heat exchange is very important.

- The working pressure of the small HEPACO heat exchangers (models: HP40 to HP150) is equal to 10 bar and the working pressure of models: HP200 to HP1500 is equal to 30bar.

- Using steam with a pressure of up to 3bar as a fluid carrier of heat energy in HEPACO integrated plate heat exchanger HP-250 is allowed.

- Interestingly, HEPACO heat exchanger HP-250 in water-to-water type has a heat transfer coefficient of 5000W / m2cº, while resource-efficient heat transfer coefficient 500w / m2cº and double sources have a heat transfer coefficient of 500 W / M2Cº and warm water sources with coils have a heat transfer coefficient of 1250 W/M2 Cº.

- In the case of applying HEPACO plate heat exchanger HP-250 for under-floor heating systems, it is recommended to consider about 136 kcal heating capacity per meter PEX pipe length on the floor.

- The reasonable price of a heat exchanger with small dimensions, low weight, and high efficiency, has very good performance efficiency.

Features of Hepaco Heat Exchanger Model HP-250

- Fuel-saving up to 30 percent would be feasible by replacing HEPACO heat exchanger HP-250 with coiled or double-jacket hot water heaters.

- HEPACO heat exchangers are provided in more than 20 different models and capacities and are always ready to supply domestic hot water instantly. They are also applied to provide Pools, buildings (floor heating), and all industrial applications heating loads.

- HEPACO plate heat exchanger HP-250 provides maximum heating load capacity and has the minimum sediment coefficient compared to all common heat exchangers, which is because of applying a special design that creates perfectly sinusoidal turbulent flows of water with minimum pressure drop.

Tips for using HEPACO plate heat exchanger HP-250

- In general, according to the deposition of mineral water’s salts after heating it, applying an appropriate softener on the cold water inlet circuit is necessary for the continued viability of all types of plate heat exchangers.

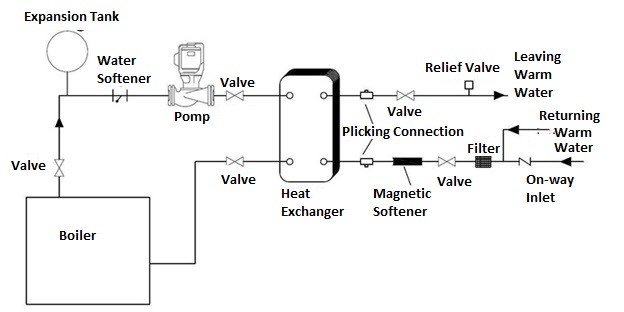

- As previously mentioned, in addition to the necessity of installing a softener on the water pipe of the heat exchanger HP-250, installation of UNION and faucet on all inlet and outlet water pipes of heat exchangers is required for the possibility of periodic services and pickling.

- According to the necessity of applying one check valve and two filters and also a linear softener (magnetic, electronic, etc.) during installation and operation of plate heat exchangers, note to order them if the required equipment is not available in your project.

- When selecting the required heat exchanger, in addition, to calculating and determining the capacity and thermal level, heat exchanger type, sizes, as well as material and working pressure of heat exchanger, a pressure drop of water passing through the coils or heat exchanger plates (and air through the heat transfer coils) must be determined to obtain the circulating pump’s head or aeration fan static pressure.

- Accurate calculation of sweep water pipes diameter in HEPACO plate heat exchangers (where water is the working fluid) will lead to sufficient supplement of needed working fluid volume in a heat exchanger.

Schematic Diagram of the Heat Exchanger Installation

Warranty and after-sales service

HEPACO plate heat exchanger HP-250 is offered with a one-year warranty and 10 years after-sales service.

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.