DamaTajhiz Booster Pump Model B.W.S.I.D.T PUMPIRAN

- Expert consultation and booster pump sizing

- Equipped with original and guaranteed electro pumps

- European valves and fittings

- Hot-dip galvanized manifolds

- Control panel by Hyundai (Korea) or Telemecanique (Schneider)

Pre-Sales Services:

Engineering consultation + capacity calculation and sizing

Flexible payment options + standard installation services

Selection and Purchase Guide for DamaTajhiz Booster Pump – Model B.W.S.I.D.T PUMPIRAN

Booster pumps, regardless of application type, working pressure, number of pumps, etc., are generally produced in two types: constant speed and variable speed.

In water supply booster pumps, an inverter is usually used to prevent electrical and mechanical shocks at the pump's startup. This allows the motor to start gently at low speed, gradually increasing the speed and power of the pump. If the maximum speed of the pump is reached and the required water flow or pressure is still not achieved, a second pump is automatically activated.

Additionally, in continuously operating water booster pumps or those used in industry and agriculture, a PLC system is used to alternate pump startups. This system is known as the “Change Over” system.

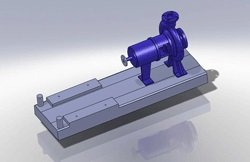

Generally, the word booster means amplifier, and a booster pump refers to one or more electric pumps connected in parallel via proper piping and related components on a suitable base frame. This system provides the required water flow and pressure for firefighting or water supply systems, especially in high-rise buildings, as well as for residential, industrial, agricultural, and swimming pool applications. If you're interested in purchasing the DamaTajhiz booster pump model B.W.S.I.D.T PENTAX (for water supply and firefighting) without high costs and long delivery times, please read the following details and contact our sales experts in the Heating & Boiler Room Equipment Department for a smooth and satisfying purchasing experience.

DamaTajhiz – Thousands of Products for Thousands of Projects (Since 2004)

Features of DamaTajhiz Booster Pump – Model B.W.S.I.D.T PUMPIRAN

- Operates on single-phase or three-phase power based on the pump motor capacity

- All bolts and nuts used in DamaTajhiz water and firefighting booster pumps are galvanized and coated

- In the B.W.S.I.D.T PUMPIRAN model, pumps are mounted on a frame, and the frame is fixed on the main structure

- This model features electric motors with speeds of either 2900 rpm or 1450 rpm

- All booster pump models include original Italian CIM or Giacomini valves, or UK-made Pex valves, and York (original) or equivalent quality non-return valves, in quantities appropriate to the number of pumps

- All water and firefighting booster pump models are equipped with Danfoss KP1 pressure switches or BD (Germany or Danfoss) pressure transmitters, 10cm pressure gauges, and original Hyundai (Korea) or Telemecanique (Schneider) control panels with a 2-year warranty

- All manifolds in DamaTajhiz booster pumps are made from properly sized galvanized pipes. Water supply booster pump manifolds are coated with three layers of food-grade epoxy paint using compressed air to ensure maximum hygiene

- The B.W.S.I.D.T PUMPIRAN model and other booster pump models include properly sized pressure tanks from top-tier brands, with valid warranties

Advantages of Variable Speed Booster Pumps

- Constant outlet water pressure even with changing consumption

- No need for a jockey (backup) pump

- Elimination of water hammer due to smooth pump start/stop

- The pumped water volume matches actual consumption needs

- Reduced wear on couplings and moving parts, leading to extended system lifespan

- Lower maintenance and service costs

- Up to 30% energy savings thanks to inverter-controlled variable speed system

- In general, all types of booster pumps (water supply, firefighting, industrial, etc.) by DamaTajhiz are produced based on project requirements — including pump type and model (such as Lowara, Pentax, Ebara, Grundfos, Pumpiran, etc.) selected by the client and approved by project consultants, and supported by DamaTajhiz’s technical experience.

- When comparing water supply and firefighting booster pump prices, pay close attention to valve and fitting quality, pump brand and power, control panel components, electrical control quality and authenticity, pump assembly quality, collector build, and overall pump performance.

Types of Firefighting Booster Pumps by DamaTajhiz

DamaTajhiz firefighting booster pumps are widely used in residential and office projects, including:

- Two-line Firefighting Booster Pump with Pentax CBT 310 Pump

Equipped with 24-liter Zilmet tank – for 5-story buildings with 5 fireboxes - Two-line Firefighting Booster Pump with Pentax CBT 600 Pump

Equipped with 24-liter Zilmet tank – for 8-story buildings with 8 fireboxes

Types of Water Booster Pumps by DamaTajhiz

DamaTajhiz water booster pumps are suitable not only for residential and commercial buildings, but also for offices, hotels, hospitals, and military/police facilities, including:

- Water Booster Pump with Pentax CBT 210 Pump

Ideal for up to 6-story buildings with 2 units per floor, each having 2 bathrooms, and an average unit area of 120–150 sqm - Water Booster Pump with Pentax CBT 310 Pump

Suitable for 8-story buildings with 2 units per floor (140 sqm avg.) and 2 bathrooms

Also suitable for 10-story buildings with 2 units per floor (90 sqm avg.) and 2 bathrooms - Water Booster Pump with Pentax CBT 600 Pump

Suitable for 8-story buildings with 4 units per floor, 120–140 sqm avg., and 2 bathrooms - Water Booster Pump with Pentax CBT 800 Pump

Ideal for 8-story buildings with 2 units per floor (120 sqm) and 2 bathrooms - Water Booster Pump with Pentax CBT 1000 Pump

Designed for 15-story buildings with 60 units, averaging 70–140 sqm, and 2 bathrooms - Water Booster Pump with Pentax CBT 160

General Tables for Calculating Booster Pump Head and Flow Rate

- Water Booster Pump Pressure (Head) Calculation Table (adapted from Grundfos Handbook)

- To determine the water pump pressure, first find the building height in the left column, then move horizontally to find the minimum booster pump pressure where it intersects with the floor area column.

- For example, the minimum pressure required for a building with a height of 50 meters and 400 square meters per floor is 7.44 atm. Also, the fire protection standard for up to 800 m² per floor using a 3/4" hose reel with a 1/4" nozzle is 1.5 atm and 8 GPM (~30 lit/min) behind the furthest and highest nozzle (when using two hose reels simultaneously).

For resident-operated fire protection using a 1.1/2" fire cabinet, the standard is 4.5 bar and 50 GPM (~190 lit/min) behind the furthest and highest cabinet (when using two cabinets simultaneously).

For firefighter-operated protection using a 2.1/2" cabinet, the standard is 6.8 bar and 250 GPM (~950 lit/min) behind the furthest and highest cabinet (again with two cabinets in use).

- Water Booster Pump Flow Rate Calculation Table (adapted from Grundfos Handbook)

Booster Pump Flow Rate Table Booster Pump Flow Rate Table

Units Single

Lit/minSingle

m³/hrDouble

Lit/minDouble

m³/hrOffice

Lit/minOffice

m³/hrHotel

Lit/minHotel

m³/hrHospital

Lit/minHospital

m³/hrBeds 6 84 5 100 6 67 4 234 14 134 8 60 9 100 6 134 8 84 5 284 17 184 11 90 12 117 7 167 10 100 6 351 21 234 14 120 15 117 7 167 10 100 6 434 26 250 15 150 18 134 8 200 12 117 7 501 30 284 17 180 21 134 8 200 12 117 7 551 33 301 18 210 24 150 9 217 13 134 8 651 39 351 21 240 30 167 10 234 14 150 9 735 44 401 24 300 36 184 11 250 15 167 10 801 48 434 26 360 42 200 12 267 16 184 11 902 54 468 28 420 48 217 13 284 17 200 12 1052 63 501 30 480 60 234 14 300 18 234 14 1202 72 568 34 600 72 250 15 317 19 250 15 1302 78 601 36 720 80 267 16 351 21 267 16 1603 96 952 57 800 90 284 17 367 22 284 17 1703 102 1002 60 900 100 300 18 384 23 284 17 1804 108 1069 64 1000 120 334 20 418 25 317 19 2104 126 1186 71 1200 150 384 23 468 28 367 22 2555 153 1352 81 1500 180 418 25 501 30 384 23 2855 171 1519 91 1800 210 451 27 534 32 418 25 3155 189 1686 101 2100 240 501 30 601 36 451 27 3606 216 1852 111 2400 300 601 36 785 47 552 33 4680 280 2254 135 3000

Note:

- (m3/h) = 4.4 (U.S. gpm)

- To determine the maximum flow rate for a residential building, first find the number of units in the left column, then move horizontally to find the flow rate under "units with one bathroom" or "units with two bathrooms".

- For example, the flow rate for a building with units having two bathrooms is 18 m³/h (about 300 lit/min).

- For commercial buildings like offices, hotels, or hospitals, find the number of people or beds in the right column, then move horizontally to find the corresponding flow rate.

- For instance, a hospital with 1,000 beds needs a booster pump with a capacity of 64 m³/h (1,069 lit/min).

- The most commonly ordered booster pump brands by contractors and engineers from DamaTajhiz include Lowara, Pentax, Grundfos, Ebara, and Pump Iran.

Pump Classification Based on Function in Booster Systems

- Main Pump

These pumps provide the required head and flow rate for the entire water supply or fire fighting system. - Jockey Pump

In systems with high flow requirements, large pumps and motors are used, which consume significant energy. However, during low-demand periods, a smaller jockey pump is used to save energy and reduce wear on the main pumps. It also compensates for pressure drops due to leaks or system losses. (Variable-speed booster pumps do not require a jockey pump.) - Standby Pump

For critical buildings like hotels, hospitals, and factories where continuous water supply is essential, a standby pump is installed. If a main pump fails, the standby unit activates to maintain uninterrupted water service.

Note: A standby pump is mandatory in fire-fighting booster systems.

DamaTajhiz — Thousands of Products for Thousands of Projects (Since 2004)

Main Components of Fixed-Speed and Variable-Speed Booster Pumps

The main components of booster pumps include electric pumps, the base frame, diaphragm or bladder tank, low and high-pressure switches, pipes, suction and discharge manifolds, fittings, and valves. Fixed-speed booster pumps also include a fixed-speed control panel, while variable-speed systems require a variable-speed control panel, inverter (VFD), and pressure transmitter. More details are provided below.

Additional Notes on Booster Pumps

- Since water demand in buildings constantly changes, failure to regulate water pressure in the pipes can cause serious issues.

- In fixed-speed systems, one or more pumps deliver a constant flow regardless of demand, causing frequent pressure fluctuations and related water supply problems.

- Sudden startup of one or more pumps can spike the water pressure, damaging pipes and valves, while sudden shutdowns can cause pressure drops and water flow interruptions.

In general, fire-fighting booster pumps must be connected to the building’s emergency power system to ensure fire suppression. According to technical and safety standards, if there is no emergency power system and a power outage occurs, at least one of the pumps in the fire-fighting booster system must be a diesel pump.

Classification of Constant-Speed Booster Pumps Based on the Number of Pumps

- Single-Pump Booster Systems:

This type of booster system is used for low to medium sanitary water demands. It is a fully integrated system where the inlet manifold connects to the water source and the outlet manifold connects to the consumption network, operated by a single pump. - Booster Pump with Jockey Pump (or lead pump):

These systems consist of one or more main pumps and a smaller-capacity pump (with the same pressure rating as the main pumps) used as a jockey pump in the circuit. - Booster Pump without Jockey Pump:

These systems include more than one main pump.

Note: In variable-speed booster pumps, there is no need to use a jockey pump as a backup.

Main Design Factors of Booster Pumps

- Maximum water consumption

- Minimum required pressure

- Hourly fluctuations in water usage

Overview of Booster Pump Components

- Electric Motor: The electric motor powers the booster pump. In multi-pump systems, two or more pumps are installed in parallel on a single base frame. The IP rating (protection level against dust and water) should be considered when selecting the motor.

- Suction Section: This includes a pipe manifold connected to the pump’s suction side and the storage tank outlet via fittings and valves.

- Shut-off Valve: Used to isolate a pump from the system. Cast iron valves are used in larger systems and brass valves in smaller ones.

- Strainer: Prevents particles in the water from damaging the pump impeller.

- Vibration Isolator: Prevents the transmission of pump vibrations to the piping network.

- Flange: Used to connect different booster components; available in welded or threaded types based on system size.

- Discharge Section: Similar to the suction section, it connects the pump outlet to the consumption network.

- Check Valve: Prevents backflow and water hammer damage.

- Electrical Control Panel: Coordinates electrical and mechanical components. It must be certified for safety and protect against voltage fluctuations, dry running, and operational sequencing.

For more information, refer to the article on booster pump control circuits on the Damatajhiz website. - Manometer: Measures input and output pressure and displays each pump’s pressure.

- Pressure Switch: Regulates and monitors minimum and maximum pressure in the booster pump system.

- Pressure Transmitter: Used in variable-speed systems to maintain constant water pressure.

- Coupling: If the motor and pump are not integrated, a coupling is used to connect them based on shaft diameter.

- Base Frame: All components (pumps, motor, panel, suction/discharge parts) are mounted on a sturdy frame for integration and vibration reduction.

- Pressure Tank (Diaphragm or Bladder Type): Since water is incompressible, pressure must remain constant. The pressure tank stores water at a set pressure and reduces frequent pump starts/stops and water hammer. While a jockey pump can eliminate the need for a tank in non-inverter systems, combining both provides better protection.

- Flange and Union

- Nipple and Reducer

- Vibration Isolator

- Shut-off Valve

Ordering and Warranty of Damatajhiz Water and Fire Booster Pumps

- All Damatajhiz water and fire booster pump models come with a 15-month golden warranty and 10 years of after-sales service.

- To view prices and technical details for purchasing Damatajhiz water booster pumps, or to learn more about fire-fighting models, click on the “Technical Specifications” tab at the top of this page.

- On the Damatajhiz specialized platform, detailed specifications, calculation methods, and guaranteed prices for water and fire booster pumps with golden warranties are offered to help you make smart, cost-effective purchases.

- We emphasize that by reviewing this content before placing your order, you can make an informed and technical decision and avoid being overcharged by other companies using brand names or vague promises.

|

|

| Application | Booster Pump Model | Number of Pumps | Pump Model Type | Max Head (m) | Max Flow (m³/hr) | Diaphragm Tank Capacity (Lit) | Flange Diameter (in) | Electrical Specifications | |||

| Suction | Discharge | RPM | KW | A | |||||||

| Water booster pump for buildings up to 7 floors with 60 units, average area between 80 to 120 sqm, with 2 bathrooms |

B.W.S.I.D.T PUMPIRAN 250~32 |

2 units | Pumpiran 250~32 |

79 | 22 | 50 | 2 | 1.1/4 | 2900 | 11.1 | 21.6 |

| Water booster pump for buildings up to 8 floors with 80 units, with 2 bathrooms, and average area from 70 to 140 sqm |

B.W.S.I.D.T PUMPIRAN 250~40 |

2 units | Pumpiran 250~40 |

85 | 58 | 50 | 2.1/2 | 1.1/2 | 2900 | 18.6 | 37.5 |

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.