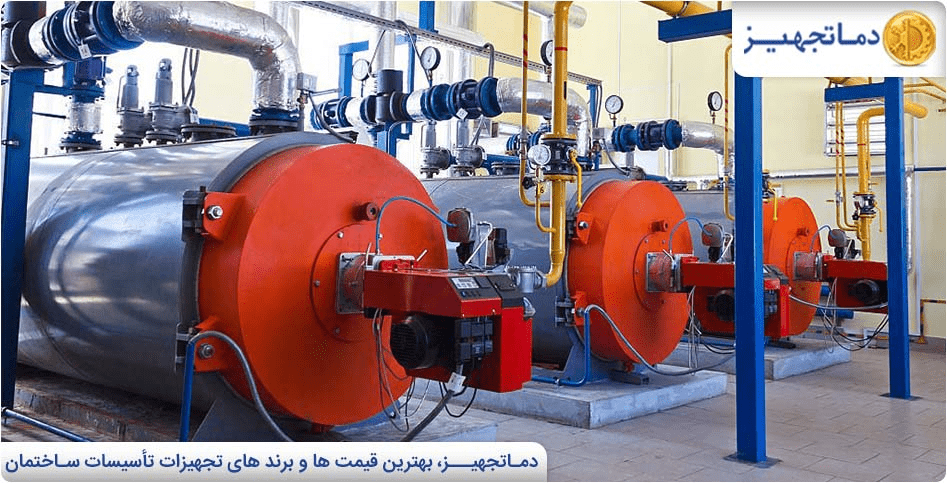

Differences Between Steel and Cast Iron Boilers

This article provides a comprehensive comparison between steel and cast-iron boilers used in central boiler rooms. Reading it will help engineers and technicians understand the key differences and make informed decisions when selecting the appropriate boiler for their projects.

Table of Contents

Fast shipping nationwide

Secure payment

Valid warranty

After-sales service

Address

Head Office: No. 463,Talebian Alley,Taleghani St.Tehran,Iran

Phone

Fax

Email

DamaTajhiz has provided the opportunity to sell and ship specialized HVAC equipment for applicants in the following countries as the first and the most popular online store for selling HVAC equipment (Heating , Ventilation , Cooling , Air conditioning) in the Middle East : Afghanistan – Tajikistan - Uzbekistan – Turkmenistan – Azerbaijan – Armenia – Georgia – Turkey – Iraq – Syria – Jordan – Kuwait – Emirates – Qatar – Oman.